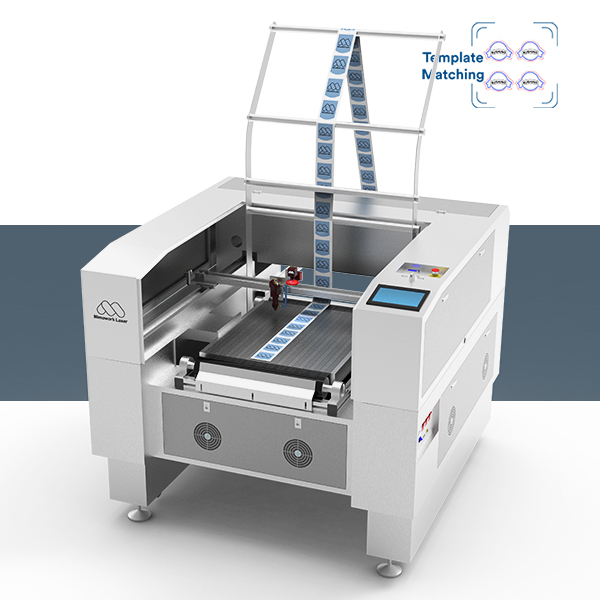

Roll Woven Label Laser Cutting Machine

(Woven label cutting machine, laser cut applique machine)

Technical Data

|

Working Area (W*L) |

400mm * 500mm (15.7” * 19.6”) |

|

Packing Size (W*L*H) |

1750mm * 1500mm * 1350mm (68.8”* 59.0”* 53.1”) |

|

Gross Weight |

440kg |

|

Software |

CCD Software |

|

Laser Power |

60W |

|

Laser Source |

CO2 Glass Laser Tube |

|

Mechanical Control System |

Step Motor Drive & Belt Control |

|

Working Table |

Mild Steel Conveyor Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Cutting Precision |

0.5mm |

|

Cooling System |

Water Chiller |

|

Electricity Supply |

220V/Single Phase/50HZ or 60HZ |

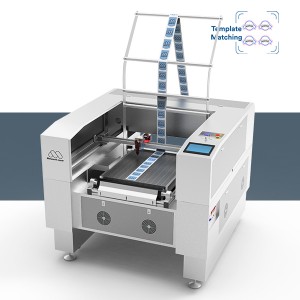

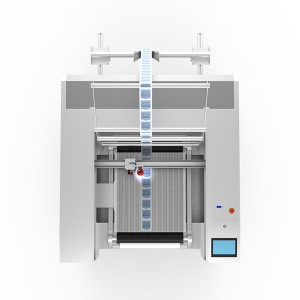

Optical Recognition System

◾ CCD Camera

As the eye of label laser cutter, the CCD Camera can accurately locate the position of the small patterns through precise calculation, and every time positioning error is only within one-thousandth of a millimeter. That provides accurate cutting instruction for the woven label laser cutting machine.

Flexible & Efficient Cutting

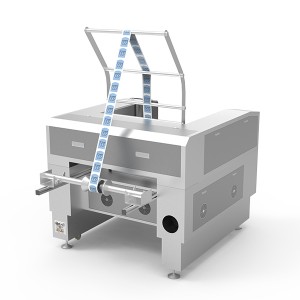

◾ Automatic Conveyor System

Specially tailored feeding device suiting the roll label cooperates well with the laser cutter machine, leading to outstanding production efficiency as well as minimum labor cost. The automatic laser design allows the whole working flow smooth and visible so that you can inspect the production condition and timely adjustment. Also vertical feeding provides the roll label with a flat surface on the working table, allowing the accurate cutting without fold and stretch.

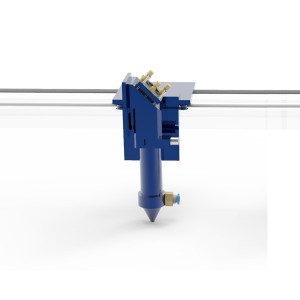

◾ Pressure Bar

Equipped behind the conveyor working table, the pressure bar take advantage of the pressure to smooth the feeding roll label to be flat. Which is benefit to complete the accurate cutting on the working table.

Stable & Safe Laser Structure

◾ Compact Laser Cutter

The small laser cutter machine comes with a little figure but flexible and reliable label cutting. Compact design occupies small space, enabling it to be placed anywhere and convenient to move. Benefiting from reliable laser machine structure with well-organized assembly, you can easily operate it and progress label production in a long service life.

◾ Signal Light

A signal light is an indispensable part to show and remind the operator of the working condition of the machine. Under the normal working condition, it shows a green signal. When the machine finishes working and stops, it would turn yellow. If the parameter is abnormally set or there’s improper operation, the machine will stop and a red alarm light will be issued to remind the operator.

◾ Emergency Button

An emergency stop, also known as a kill switch (E-stop), is a safety mechanism used to shut down a machine in an emergency when it cannot be shut down in the usual way. The emergency stop ensures the safety of operators during the production process.

◾ Air Pump

When laser cutting label, patch and other printed materials, some fume and particle from hot cutting will appear. The air blower can sweep away the extra residues and heat to keep the materials clean and flat without damage. That not only improves the cutting quality but protects the lens being damaged.

◾ CE Certification

Owning the legal right of marketing and distributing, MimoWork Laser Machine has been proud of its solid and reliable quality.

The fume extractor, together with the exhaust fan, can absorb the wast gas, pungent odor and airborne residues. There are different types and formats to select according to actual patch production. On the one hand, the optional filtration system ensures the clean working environment, and the other one is about to environment protection by purifying the waste.

The size of laser cutting table depends on the material format. MimoWork offers diverse working table areas to be select according to woven label production demand and material sizes.

Customize your own label laser cutter machine

We are here to help you!

Laser Cutting Labels Samples

▷ Pictures Browse

• Washing care label

• Logo label

• Adhesive label

• Mattress label

• Hang tag

• Embroidery label

• Pillow label

• Sticker

• Applique

▷ Video Demonstration

How to Cut Roll Woven Label with Laser Cutter

⇩ Why choose label laser cutting

◆ Accurate pattern cutting suit varieties of designs

◆ High precision through fine laser beam and digital control

◆ Clean & smooth edge with timely heat sealing

◆ Automatic feeding and cutting without manual intervention

…