Die Board Cutting Machine Quotes - 60W CO2 Laser Engraver – MimoWork Laser

Die Board Cutting Machine Quotes - 60W CO2 Laser Engraver – MimoWork Laser Detail:

Technical Data

60W CO2 Laser Engraver – Best laser engraving machine to get started

|

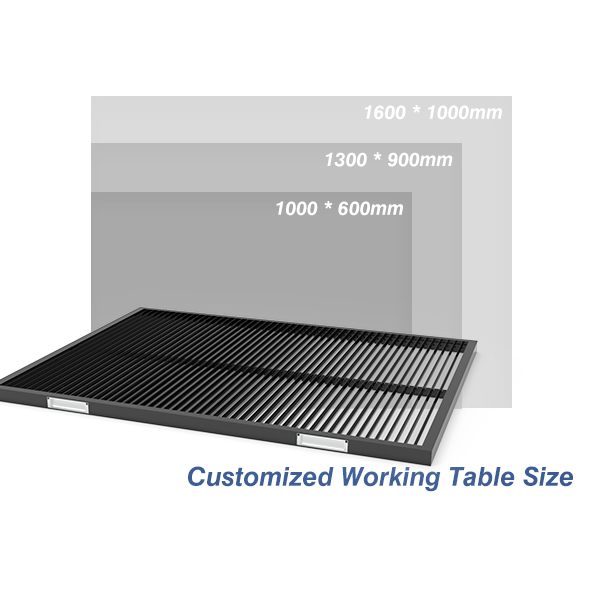

Working Area (W *L) |

1000mm * 600mm (39.3” * 23.6 ”) 1300mm * 900mm(51.2” * 35.4 ”) 1600mm * 1000mm(62.9” * 39.3 ”) <Customized Table Sizes Available> |

|

Software |

Offline Software |

|

Laser Power |

60W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

1750mm * 1350mm * 1270mm |

|

Weight |

385kg |

* Higher Power Output Laser Tube Upgrades Available

Upgrade options for you to choose

Rotary Device

If you want to engrave on the cylindrical items, the rotary attachment can meet your needs and achieve a flexible and uniform dimensional effect with a more precise carved depth. Plugin the wire into the right places, the general Y-axis movement turns into the rotary direction, which solves the unevenness of engraved traces with the changeable distance from the laser spot to the round material’s surface on the plane.

Servo Motors

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops. Servo motors ensure higher speed and higher precision of the laser cutting and engraving.

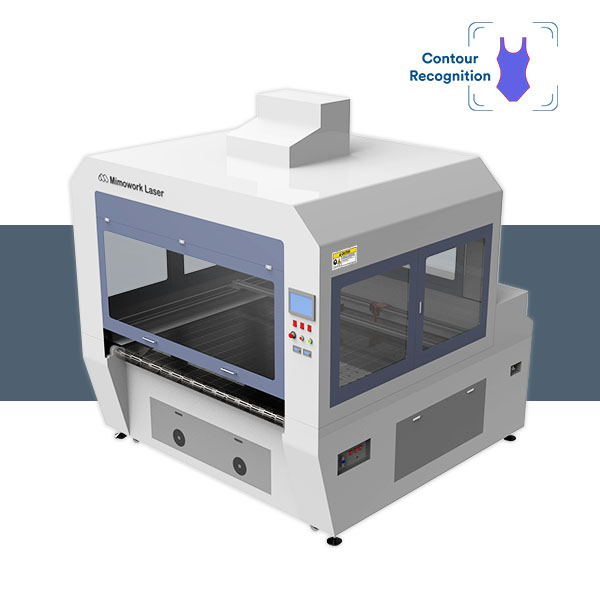

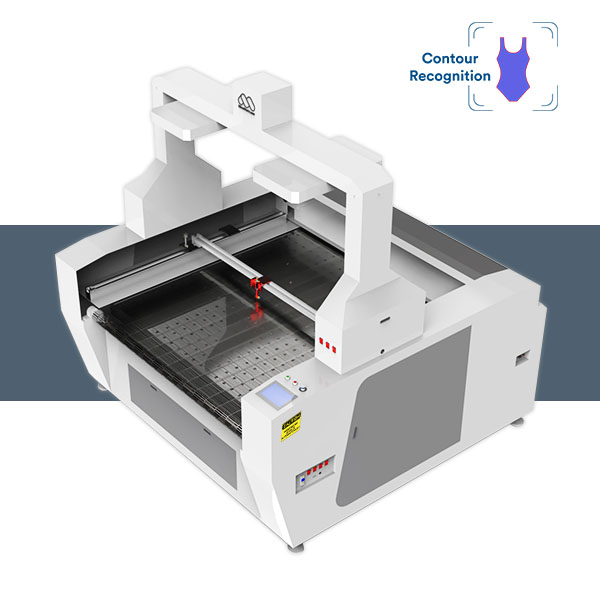

CCD Camera

CCD Camera can recognize and locate the printed pattern on the materials to assist the laser with accurate cutting. Signage, plaques, artwork and wood photo, branding logos, and even memorable gifts made of printed wood, printed acrylic, and other printed materials can be easily processed. The CCD camera is equipped beside the laser head to search for the workpiece using registration marks at the start of the cutting procedure. Through this way, printed, woven, and embroidered fiducial marks as well as other high-contrast contours can be visually scanned so that the laser cutter camera can know where the actual position and dimension of the workpieces are, achieving a precise pattern laser cutting design.

Brushless DC Motors

Brushless DC (direct current) motor can run at a high RPM (revolutions per minute). The stator of the DC motor provides a rotating magnetic field that drives the armature to rotate. Among all the motors, the brushless dc motor can provide the most powerful kinetic energy and drive the laser head to move at tremendous speed. MimoWork’s best CO2 laser engraving machine is equipped with a brushless motor and can reach a maximum engraving speed of 2000mm/s. The brushless dc motor is rarely seen in a CO2 laser cutting machine. This is because the speed of cutting through a material is limited by the thickness of the materials. On the contrary, you only need small power to carve graphics on your materials, A brushless motor equipped with the laser engraver will shorten your engraving time with greater accuracy.

>> More details about motors

Have specific needs for your machine?

Tell us your requirements

Video Display

▷ Laser Cutting & Engraving Paper

▷ Laser Engraving Characters on Wood

Compatible wood materials:

MDF, Plywood, Bamboo, Balsa Wood, Beech, Cherry, Chipboard, Cork, Hardwood, Laminated Wood, Multiplex, Natural Wood, Oak, Solid Wood, Timber, Teak, Veneers, Walnut…

Contact Us for Inquire to get Started Right Away!

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high quality regulate, reasonable price tag, excellent support and close co-operation with shoppers, we have been devoted to furnishing the best benefit for our buyers for Die Board Cutting Machine Quotes - 60W CO2 Laser Engraver – MimoWork Laser , The product will supply to all over the world, such as: Oslo , Islamabad , Slovenia , Company name, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly