Excellent quality Can A Laser Engraver Cut Vinyl - Cardboard Laser Cutting Machine – MimoWork Laser

Excellent quality Can A Laser Engraver Cut Vinyl - Cardboard Laser Cutting Machine – MimoWork Laser Detail:

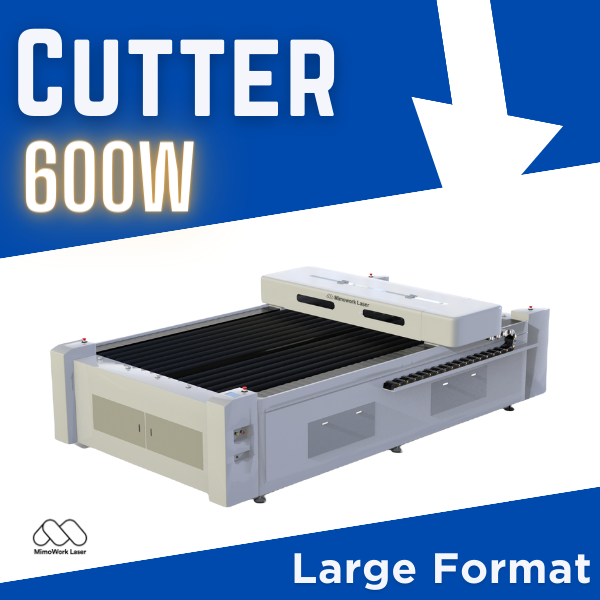

▶ MimoWork Laser Cardboard Cutting Machine

Technical Data

|

Working Area (W *L) |

1300mm * 900mm(51.2” * 35.4 ”) <Customized Laser Cutting Table Sizes> |

|

Software |

Offline Software |

|

Laser Power |

40W/60W/80W/100W/150W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

1750mm * 1350mm * 1270mm |

|

Weight |

385kg |

▶ Full of Productivity and Durability

Machine Structure Features

✦ Strong Machine Case

- Long Service Life

✦ Enclosed Design

- Safe Production

✦ CNC System

- High Automation

✦ Stable Gantry

- Consistent Working

◼ Well-Performed Exhaust System

All MimoWork Laser Machines are equipped with a well-performed Exhaust System, including the cardboard laser cutting machine. When laser cutting cardboard or other paper products, the smoke and fume produced will be absorbed by the exhaust system and discharged to the outside. Based on the size and power of the laser machine, the exhaust system is customized in ventilation volume and speed, to maximize the great cutting effect.

If you have higher requirements for the cleanliness and safety of the working environment, we have a upgraded ventilation solution – a fume extractor.

◼ Air Assist Pump

This air assist for laser machine directs a focused stream of air onto the cutting area, which is designed to optimize your cutting and engraving tasks, especially when working with materials like cardboard.

For one thing, the air assist for the laser cutter can effectively clear away the smoke, debris, and vaporized particles during laser cutting cardboard or other materials, ensuring a clean and precise cut.

Additionally, the air assist reduces the risk of material scorching and minimizes the chances of fire, making your cutting and engraving operations safer and more efficient.

◼ Honeycomb Laser Cutting Bed

The honeycomb laser cutting bed supports a wide range of materials while allowing the laser beam to pass through the workpiece with minimal reflection, ensuring the material surfaces are clean and intact.

The honeycomb structure provides excellent airflow during cutting and engraving, which helps prevent the material from overheating, reduces the risk of burn marks on the underside of the workpiece, and effectively removes smoke and debris.

We recommend the honeycomb table for cardboard laser cutting machine, for your high degree of quality and consistency in laser-cut projects.

One Tip:

You can use small magnets to hold your cardboard in place on the honeycomb bed. The magnets adhere to the metal table, keeping the material flat and securely positioned during cutting, ensuring even greater precision in your projects.

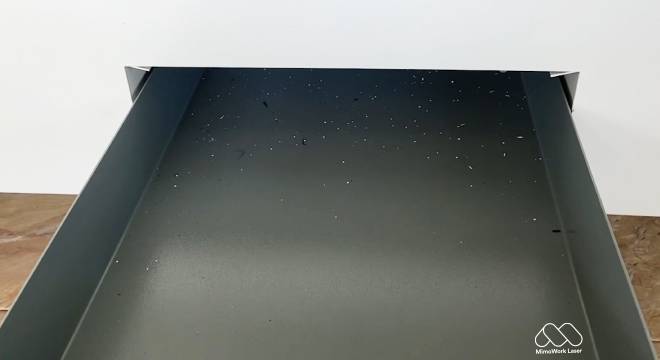

◼ Dust Collection Compartment

The dust collection area is located below the honeycomb laser cutting table, designed for collecting the finished pieces of laser cutting, waste, and fragment dropping from the cutting area. After laser cutting, you can open the drawer, take out the waste, and clean the inside. It’s more convenient for cleaning, and significant for next laser cutting and engraving.

If there is debris left on the working table, the material to be cut will be contaminated.

▶ Upgrade Your Carboard Production into Top Level

Advanced Laser Options

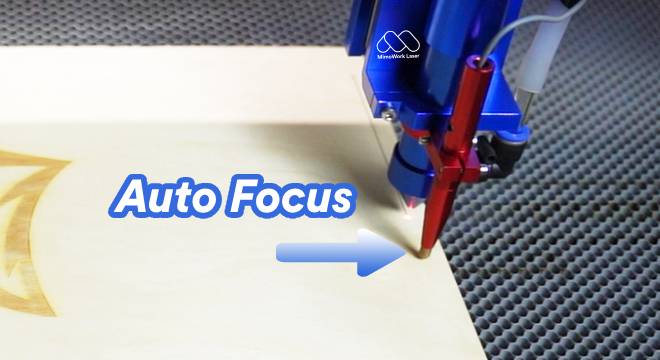

Auto Focus Device

The auto-focus device is an advanced upgrade for your cardboard laser cutting machine, designed to automatically adjust the distance between the laser head nozzle and the material being cut or engraved. This smart feature accurately finds the optimal focal length, ensuring precise and consistent laser performance across your projects. Without manual calibration, the auto-focus device improves your work more precisely and efficiently.

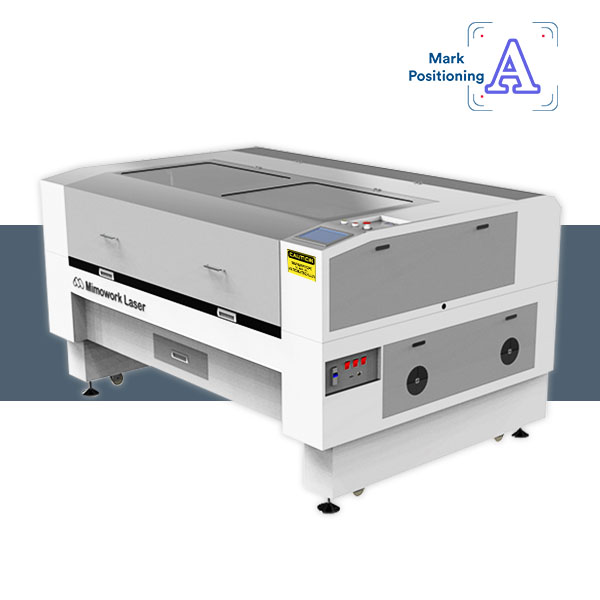

CCD Camera

For the printed paper like business card, poster, sticker and others, accurate cutting along the pattern contour is of significant importance. CCD Camera System offers contour cutting guidance by recognizing the feature area, which is easy to operate and eliminates unnecessary post-processing.

Servo Motors

Servo motors ensure higher speed and higher precision of the laser cutting and engraving. A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops.

Brushless DC Motors

Brushless DC (direct current) motor can run at a high RPM (revolutions per minute). The stator of the DC motor provides a rotating magnetic field that drives the armature to rotate. Among all the motors, the brushless dc motor can provide the most powerful kinetic energy and drive the laser head to move at tremendous speed. MimoWork’s best CO2 laser engraving machine is equipped with a brushless motor and can reach a maximum engraving speed of 2000mm/s. You only need small power to engrave graphics on the paper, a brushless motor equipped with the laser engraver will shorten your engraving time with greater accuracy.

Select Suitable Laser Configurations to Improve Your Production

Any Questions or Any Insights?

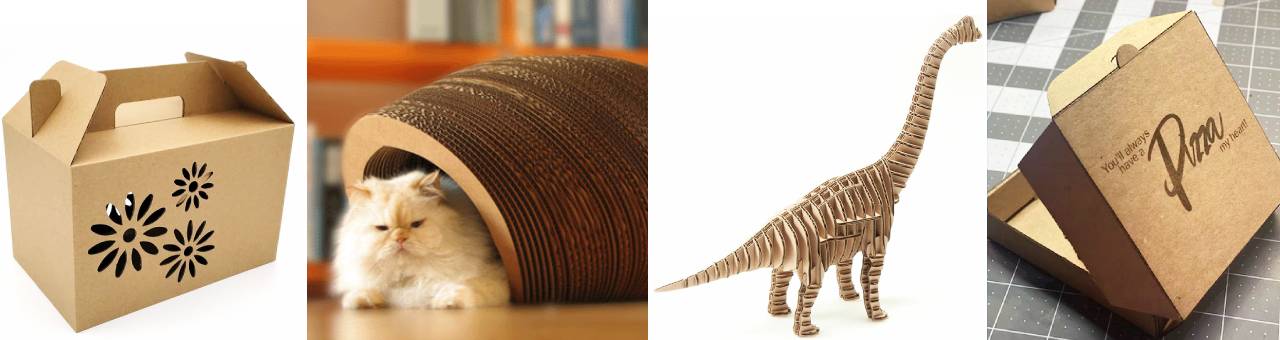

▶ With Cardboard Laser Cutting Machine

You Can Make

Video: DIY Cat House with Laser Cutting Cardboard

>> More about Laser Cutting Paper

Special Applications for Paper Laser Cutting

Check out the videos >>

Fast Laser Engraving Invitation Card

Custom Laser Cut Paper Craft

Laser Cut Multi-layer Paper

What is Your Paper Idea?

Let the Paper Laser Cutter Help You!

Related Laser Paper Cutter Machine

Galvo Laser Engraver & Cutter 40

• Working Area: 400mm * 400mm

• Laser Power: 180W/250W/500W

• Max Cutting Speed: 1000mm/s

• Max Marking Speed: 10,000mm/s

Paper Laser Cutter 1060

• Working Area: 1000mm * 600mm

• Laser Power: 40W/60W/80W/100W

• Max Cutting Speed: 400mm/s

Customized Table Sizes Available

MimoWork Laser Provides!

Professional and affordable paper laser cutter

FAQ – Y’all Got Questions, We Got Answers

1. How to Find the Optimal Focal Length?

The focal length can be quite different, depending on the type of lens you have in your laser head. To start you need to make sure that one piece of cardboard is on an angle, use one scrap to wedge the cardboard. Now engrave a straight line on your piece of cardboard with the laser.

When that’s done, take a close look at your line and find the point where the line is the thinnest.

Use the focal ruler to measure the distance between the smallest point you marked and the tip of your laser head. This is the right focal length for your particular lens.

>> Check out More Tutorial Details

2. Which Cardboard Type is Suitable for Laser Cutting?

Corrugated cardboard stands out as the preferred choice for laser-cutting projects demanding structural integrity.

It offers affordability, is available in diverse sizes and thicknesses, and is amenable to effortless laser cutting and engraving.

A frequently used variety of corrugated cardboard for laser cutting is the 2-mm-thick single-wall, double-face board.

>> More about Laser Cutting Cardboard

Related Articles

Stunning Laser Cut Paper Designs

How to Laser Cut Paper without Burning it?

How Laser Galvo Works? CO2 Galvo Laser Engraver

Any Questions about the Cardboard Laser Cutting Machine?

Product detail pictures:

Related Product Guide:

Our aim would be to fulfill our shoppers by offering golden company, very good value and good quality for Excellent quality Can A Laser Engraver Cut Vinyl - Cardboard Laser Cutting Machine – MimoWork Laser , The product will supply to all over the world, such as: Colombia , Uruguay , New York , Our team knows well the market demands in different countries, and is capable of supplying suitable quality products and solutions at the best prices to different markets. Our company has already set up a experienced, creative and responsible team to develop clients with the multi-win principle.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.