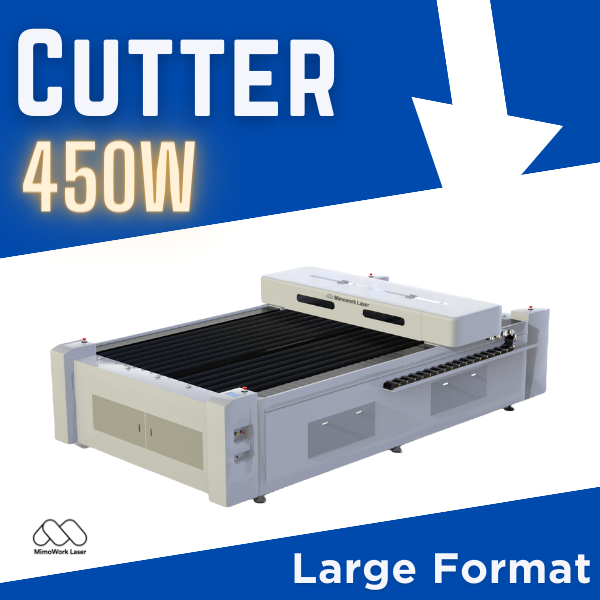

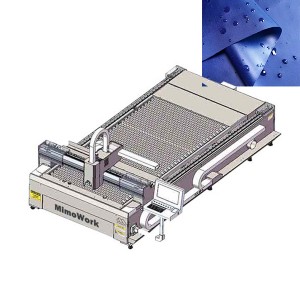

450W Laser Cutter (Large Format)

▶ Large Format Laser Cutter for Tough Cuts

Technical Data

|

Working Area (W * L) |

1300mm * 2500mm (51” * 98.4”) |

|

Software |

Offline Software |

|

Laser Power |

450W |

|

Laser Source |

CO2 Glass Laser Tube |

|

Mechanical Control System |

Ball Screw & Servo Motor Drive |

|

Working Table |

Knife Blade or Honeycomb Working Table |

|

Max Speed |

1~600mm/s |

|

Acceleration Speed |

1000~3000mm/s2 |

|

Position Accuracy |

≤±0.05mm |

|

Machine Size |

3800 * 1960 * 1210mm |

|

Operating Voltage |

AC110-220V±10%,50-60HZ |

|

Cooling Mode |

Water Cooling and Protection System |

|

Working Environment |

Temperature:0—45℃ Humidity:5%—95% |

|

Package Size |

3850mm * 2050mm *1270mm |

|

Weight |

1000kg |

Design Highlights of the 500W Laser Cutter (Large Format)

A Giant Leap in Productivity

◾ Stable & Excellent Cutting Quality

Constant Optical Path Design

With the optimal output optical path length, the consistent laser beam at any point in the range of the cutting table can result in an even cut through the entire material, regardless of thickness. Thanks to that, you can get a better cutting effect for acrylic or wood than the half-flying laser path.

◾ High Efficiency and Precision

Efficient Transmission System

The X-axis precision screw module and Y-axis unilateral ball screw provide excellent stability and precision for the high-speed movement of the gantry. Combined with a servo motor, the transmission system creates fairly high production efficiency.

◾ Durable & Long Service Life

Stable Mechanical Structure

The machine body is welded with a 100mm square tube and undergoes vibration aging and natural aging treatment. The gantry and cutting head use integrated aluminum. The overall configuration ensures a stable working state.

◾ High speed processing

High Speed of Cutting & Engraving

Our 1300*2500mm laser cutter can achieve 1-60,000mm /min engraving speed and 1-36,000mm/min cutting speed.

At the same time, position accuracy is also guaranteed within 0.05mm, so that it can cut and engrave 1x1mm numbers or letters, totally no problem.

Why choose MimoWork Laser

130250 Large Format 450W Laser Machine Details Comparison

|

|

Other manufacturer’s |

MimoWork laser machine |

|

Cutting speed |

1-15,000mm/min |

1-36,000mm/min |

|

Engraving speed |

1-15,000mm/min |

1-60,000mm/min |

|

Position accuracy |

≤±0.2mm |

≤±0.05mm |

|

Laser power |

80W/100W/130W/150W |

100W/130W/150W/300W/500W |

|

Laser path |

Half-fly laser path |

Constant optical path |

|

Transmission system |

Transmission belt |

Servo motor + Ball screw |

|

Driving system |

Step driver |

Servo motor |

|

Control system |

The old system, out of the sale |

New popular RDC control system |

|

Optional electrical design |

No |

CE/UL/CSA |

|

Main body |

Traditional welding fuselage |

Reinforced bed, the overall structure is welded with a 100mm square tube and undergoes vibration aging and natural aging treatment. |

Samples From 450W Large Format Laser Cutter Cutting Wood

Suitable wood materials

MDF, Basswood, White Pine, Alder, Cherry, Oak, Baltic Birch Plywood, Balsa, Cork, Cedar, Balsa, Solid Wood, Plywood, Timber, Teak, Veneers, Walnut, Hardwood, Laminated Wood and Multiplex

Wide applications

• Furniture

• Signage

• Company Logo

• Letters

• Woodwork

• Die Boards

• Instruments

• Storage Box

• Architectural Models

• Decorating Floor Inlays

▶ 500W Large Format Laser Cutter

Upgrade Options for you to Choose

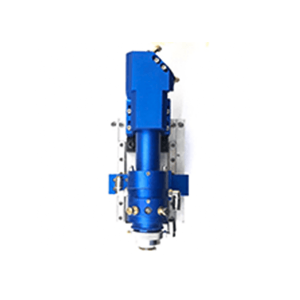

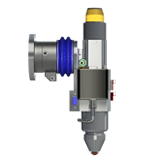

Mixed Laser Head

Auto Focus

The CCD Camera can recognize and position the pattern on the printed acrylic, assisting laser cutter to realize accurate cutting with high quality. Any customized graphic design printed can be flexibly processed along the outline with the optical system, playing an important part in advertising and other industry.

With this cutting-edge upgrade, you can boost your machine's laser power output up to an impressive 600W, allowing you to cut even thicker and tougher materials with ease. Our Upgradable Laser Tube is designed to be easy to install, meaning you can quickly and easily upgrade your existing laser cutting machine without the need for complicated and time-consuming modifications. This makes it an ideal solution for businesses that are looking to increase their production capabilities and expand their range of services. By upgrading to our Upgradable Laser Tube, you'll be able to cut through a wide variety of materials with precision and accuracy. Whether you're working with wood, acrylic, metal, or other solid materials, our laser tube is up to the task. The high power output means that even the thickest materials can be cut with ease, giving you greater flexibility and versatility in your work.