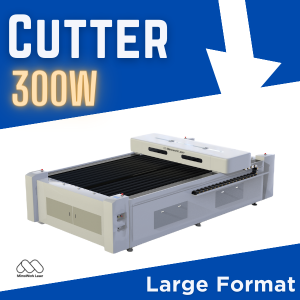

Cordura Fabric Laser Cutter

▶ Cordura Laser Cutter 160

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Servo Motor Upgrade Available

Features of Cordura Laser Cutter

Swift and powerful cutting

Huge energy from the laser source can be turned into heat when contacting the Cordura fabric. That will instantly cut through (just to say melt through) the synthetic fabric, and seal the edge in virtue of the heat from laser cutting.

High speed & high efficiency

According to the powerful laser beam, the laser head can be contact-less to the material. The force-free processing greatly improves the cutting speed whilst ensuring no any damage and fray for the Cordura fabric. Plus with the CNC system and auto conveyor system, laser cutter enhances the efficiency to realize the smooth and continuous cutting. Precision and high efficiency coexists side by side.

Flexible cutting as design pattern

Just import the cutting file, the laser system will auto treat the image and convey the instruction to the laser head. Fully in accordance with your design pattern, fine laser beam without any shape limitation can draw the cutting trace on the Cordura. Flexible curving cutting gives great freedom on the design pattern. Customized working table allows different formats of Cordura.

Mechanical Structure

Automation Components

Conveyor table is very fit for the coiled fabric, providing great convenience for materials auto-conveying and cutting. Also with the aid of an auto-feeder, the whole workflow can be connected smoothly.

With the aid of the exhaust fan, the fabric can be fastened on the working table by strong suction. That makes the fabric remain flat and stable to realize accurate cutting without manual and tool fixes.

Safe & Stable Structure

- Signal Light

Signal light can indicate the working situation and functions exerting of laser machine, helps you to do the right judgment and operation.

- Emergency Button

Happen to some sudden and unexpected condition, the emergency button will be your safety guarantee by stopping the machine at once. Safe production is always the first code.

- Safe Circuit

Smooth operation makes a requirement for the function-well circuit, whose safety is the premise of safety production. All electrical components are installed strictly according to CE standards.

- Enclosed Design

Higher level of safety and convenience! Taking the varieties of fabrics and working environment into account, we design the enclosed structure for the clients with specific requirements. You can check out the cutting condition through the acrylic window, or timely monitor it by the computer.

R&D for Flexible Material Cutting

Can you Laser-Cut Cordura?

Here are Some Key Points to Keep in Mind when Laser Cutting Cordura:

Video Showcase: Cordura Laser Cutting

Samples of Laser Cutting Cordura

Video Showcase: Cordura Vest Laser Cutting

Find more videos about our laser cutters at our Video Gallery

Cordura® Cutting Test

1050D Cordura® fabric is tested that has an excellent laser cutting ability

◆ No Pull Deformation with Contactless Processing

◆ Crisp & Clean Edge without Burr

◆ Flexible Cutting for Any Shapes and Sizes

Pictures Browse

• Cordura® Patch

• Cordura® Package

• Cordura® Backpack

• Cordura® Watch Strap

• Waterproof Cordura Nylon Bag

• Cordura® Motorcycle Pants

• Cordura® Seat Cover

• Cordura® Jacket

• Ballistic Jacket

• Cordura® Wallet

• Protective Vest

Related Fabric Cutter Laser

• Laser Power: 150W/300W/500W

• Working Area (W *L): 1600mm * 3000mm

• Laser Power: 100W/150W/300W

• Working Area (W *L): 1800mm * 1000mm

• Laser Power: 100W / 150W / 300W

• Working Area (W *L): 1600mm * 1000mm

• Collecting Area (W *L): 1600mm * 500mm