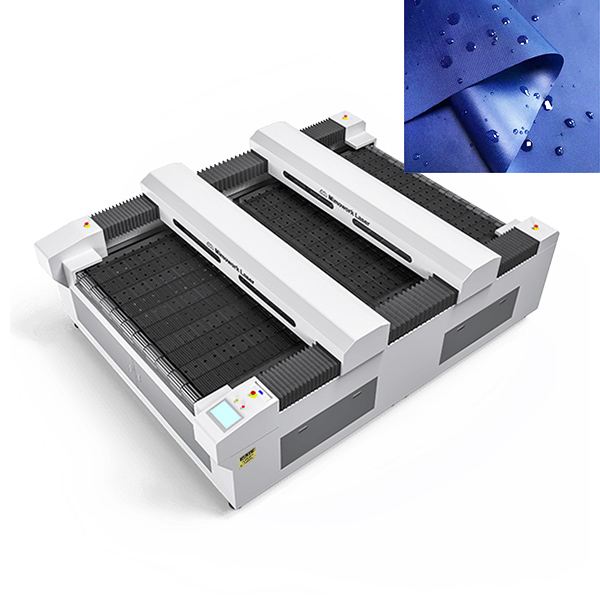

Industrial Laser Cutter for Fabric

▶ Industrial fabric laser cutting machine

Technical Data

| Working Area (W * L) | 1600mm * 3000mm (62.9’’ *118’’) |

| Max Material Width | 1600mm (62.9’’) |

| Software | Offline Software |

| Laser Power | 150W/300W/450W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Rack & Pinion Transmission and Servo Motor Driven |

| Working Table | Conveyor Working Table |

| Max Speed | 1~600mm/s |

| Acceleration Speed | 1000~6000mm/s2 |

* Two independent laser gantries are available to double your efficiency.

Mechanical Structure

▶ High Efficiency & High Output

- Two independent laser gantries

Two independent laser gantries lead the two laser heads to achieve fabric cutting in different positions. Simultaneous laser cutting doubles productivity and efficiency. The advantage especially stands out on the large format working table.

The working area of 1600mm * 3000mm (62.9’’ *118’’) can carry more materials at one time. Plus with the dual laser heads and conveyor table, automatic conveying and continuous cutting speed up the production process.

▶ Excellent Cutting Quality

The servo motor features high levels of torque at high speed. It can deliver higher precision on position the gantry and the laser head than the stepper motor does.

- High power

To meet more strict demands for large formats and thick materials, the industrial fabric laser cutting machine is equipped with high laser powers of 150W/300W/500W. That is favorable to some composite materials and resistant outdoor equipment cutting.

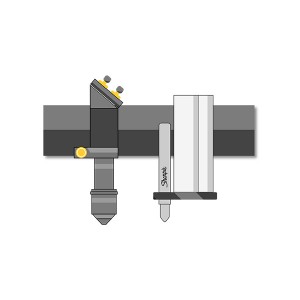

- Fine laser beam

▶ Safe & Stable Structure

- Signal light

Due to the automatic processing of our laser cutters, it is often the case that the operator is not at the machine. A signal light would be an indispensable part that can show and remind the operator of the working condition of the machine. Under the normal working condition, it shows a green signal. When the machine finishes working and stops, it would turn yellow. If the parameter is abnormally set or there’s improper operation, the machine will stop and a red alarm light will be issued to remind the operator.

- Emergency button

When the improper operation causes some emergent risk to one’s safety, this button can be pushed down and cut off the machine power immediately. When everything’s clear, only releasing the emergency button, then switching on the power can make the machine power on back to work.

- Safe circuit

Circuits are an important part of the machinery, which guarantees the operators’ safety and machines’ normal operation. All circuit layouts of our machines are using CE & FDA standard electrical specifications. When there comes to be an overload, short circuit, etc., our electronic circuit prevents malfunction by stopping the flow of current.

Under the working table of our laser machines, there is a vacuum suction system, which is connected to our powerful exhausting blowers. Besides the great effect of smoke exhausting, this system would provide good adsorption of the materials that are put on the working table, as a result, the the thin materials especially fabrics are extremely flat during cutting.

R&D for Flexible Material Cutting

CO2 RF Laser Source - Option

Video Example: Cut & Mark Fabric for Sewing with Laser

Fabric Samples from Large Fabric Cutter

Video Display

Cordura Fabric Laser Cutting

— protective vest

◆ Cutting through the fabric at one time, no adhesion

◆ No thread residue, no burr

◆ Flexible cutting for any shapes and sizes

Laser-friendly Fabrics:

nylon, aramid, Kevlar, Cordura, denim, filter cloth, fiberglass, polyester, felt, EVA, coated fabric, etc.

Pictures Browse

• Work Cloths

• Bullet Proof Clothing

• Firefighter Uniform

How Much is an Industrial Laser Cutter for Fabric?

The cost of an industrial laser cutter for fabric can vary widely depending on several factors, including the model, size, CO2 laser type (glass laser tube or RF laser tube), laser power, cutting speed, and additional features. Industrial laser cutters for fabric are designed for high-volume and precision cutting applications.

Here are Some Approximate Price Ranges for Industrial Laser Cutters for Fabric:

1. Entry-Level Industrial Laser Cutters:

These machines come with small fixed working tables, and typically start at around $3,000 to $4,500. They are suitable for small to medium-sized businesses with moderate cutting needs from fabric piece to piece.

2. Mid-Range Industrial Laser Cutters:

Mid-range models with larger working areas, higher laser powers, and more advanced features can range from $4,500 to $6,800. These machines are suitable for medium businesses with higher production volumes.

3. High-End Industrial Laser Cutters:

Larger, high-power and fully automated industrial laser cutters can range from $6,800 to over a million dollars. These machines are designed for large scale manufacturing and can handle heavy-duty cutting tasks.

4. Custom and Specialized Machines:

If you require highly specialized features, custom-built machines, or laser cutters with unique capabilities, the price can vary significantly.

In Addition to the Initial Machine Cost:

It's important to consider other expenses such as installation, training, maintenance, and any necessary software or accessories. Keep in mind that the cost of operating the laser cutter, including electricity and maintenance, should also be factored into your budget.

To get an accurate quote for an industrial laser cutter for fabric that suits your specific requirements, it's recommended to contact MimoWork Laser directly, provide them with detailed information about your needs, and request a customized quote. Consulting MimoWork Laser will help you make an informed decision and choose the best laser cutter for your business.

Related Fabric Laser Cutters

• Laser Power: 100W/150W/300W

• Working Area (W *L): 1800mm * 1000mm

• Laser Power: 150W/300W/450W

• Working Area (W *L): 1600mm * 3000mm