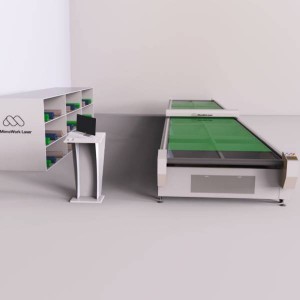

Large format Laser Cutting Machine for Fabric(10 Meters Industrial Laser Cutter)

Features of the Large Format Laser Cutter

The large format laser cutting machine adopts a 10 meters long working table, to accomdate utlra-long fabrics, realize large-size patterns cutting. We equip the machine with the gear & rack transmission and servo moter, supporting machine running smoothly and cutting precisely. Not only steady machine structure, but we custom the working table and safety device, to help with production.

◾ Customized Honey Comb Table

To keep the fabric flat and intact, we design a new honey comb table with smaller holes to support the fabrics and textiles. During machine running, the exhaust fan will provide a stronger suction to the fabric through smaller holes, ensuring cutting precise and smoothly without any fabric distortion.

◾ Safety Light Shield

The laser beam is covered by the safety light shield, like a fully closed beam path, get rid of the risk of any laser beam leakage and human touch. The laser tube, mirrors and lens are integrated installed in the device, even if for large-size working area, the cutting can be guaranteed to run steadily and consistently.

◾ High Power Water Chiller

For the ultra-long laser cutting machine, we equipe a the S&A CW-5200 series refrigerating water chiller, featuring a compact design, low energy/running cost and integrated alarm system for protection of your laser tube. This unit has been designed to work with laser machines up to and including 150W power.

◾ Emergency Stop Button

The emergency stop button is a critical safety feature on laser cutting machines, providing operators with a quick and effective way to halt machine operations and prevent potential accidents or injuries in emergency situations.

◾ Remote Control

Besides the control panel built-in the laser machine, we equip a remote control to facilitate your production. You can manage and control the machine's operations from a distance. The remote control for a large format laser cutting machine serves as a convenient and efficient tool for operators.

◾ Computer & Software for Machine

We equip the machine with a computer for work. Laser cutting software and other software meeting your requirements will be built into the computer, you can use it after plugging in. To help you with automatic production, we are always here for you.

◾ Universal Wheel

For the convenience of moving the machine, we install the universal wheel(pulley) under the machine. Considering your flexible production and the heavy machine, the universal wheel can greatly reduce moving costs, meeting various working space.

✦ Cost-Effective Price

✦ Reliable Quality

✦ Consult Laser Expert

✦ Installation & Training

As a first-class Laser Machine Manufacturer in China, we support every client in the whole production cycle with professional laser technology and considerate service. From the pre-purchase consultation, personal laser solution advice, shipping delivery, to the post-training, installation, and production, MimoWork is always here to offer help.

...

Wide Materials Compatibility:

CO2 Laser Cutting has a natural advantage in cutting fabrics and textiles due to the premium wavelength absorption. You will get an excellent cutting effect using the large format laser cutter. You will get a clean edge, precise cutting pattern, and flat and intact cloth without distortion, all of which you will get from a professional CO2 laser cutting machine.

▶ Ultra-Long Fabric Laser Cutting Machine

Upgrade Your Production (optional)

Quiet Exhaust Fan

These fans are specially designed to minimize noise levels during operation, creating a quieter and more comfortable working environment for operators. In addition to noise reduction, they efficiently remove fumes, smoke, and odors generated during laser cutting processes, ensuring optimal air quality in the workspace.

Fabric Spreading Machine

Fabric spreading machines are essential tools in the textile and garment industries, designed to efficiently and accurately lay out fabric layers for cutting. Integrated with cutting systems like laser cutters or CNC machines, fabric spreading machines enhance productivity, accuracy, and workflow efficiency in garment production, making them indispensable in modern textile manufacturing processes.

Auto Feeder is a feeding unit that runs synchronously with the laser cutting machine. The feeder will convey the roll materials to the cutting table after you put the rolls on the feeder. Feeding speed can be set according to your cutting speed. A sensor is equipped to ensure perfect material positioning and minimize errors. The feeder is able to attach different shaft diameters of rolls. The pneumatic roller can adapt textiles with various tension and thickness. This unit helps you to realize a completely automatic cutting process. Using it with a conveyor table is a great choice.

Ink-Jet Printing is widely used for marking and coding products and packages. A high-pressure pump directs liquid ink from a reservoir through a gun-body and a microscopic nozzle, creating a continuous stream of ink droplets via the Plateau-Rayleigh instability. The ink-jet printing technology is a non-contact process and has a wider application in terms of different types of materials. Moreover, inks are also options, like volatile ink or non-volatile ink, MimoWork loves to help to choose according to your needs.

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further manual intervention.

MimoWork Laser Filtration System can help one puzzle out the bothersome dust and fumes while minimizing disruption to production. Melting the surface of the material to achieve the perfect cutting result, CO2 laser processing may generate lingering gases, pungent odor, and airborne residues when you are cutting synthetic chemical materials and the CNC router can't deliver the same precision that laser does.

Related Laser Machine

• Working Area: 1600mm * 1000mm

• Laser Power: 100W/150W/300W

• Working Area: 1600mm * 3000mm

• Collection Area: 1600mm * 500mm

• Laser Power: 100W/150W/300W

• Working Area: 1600mm * 3000mm

• Laser Power: 150W/300W/450W