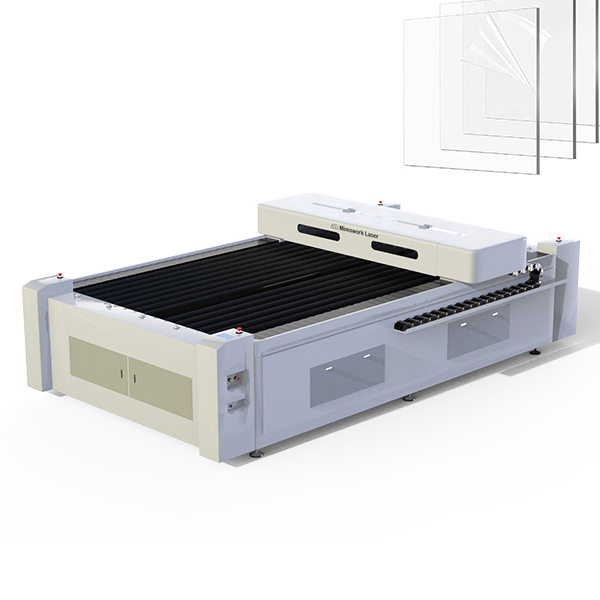

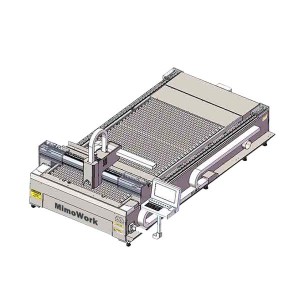

CO2 Laser Cutting Machine for Acrylic Sheet

▶ acrylic sheet laser cutting machine

Technical Data

|

Working Area (W * L) |

1300mm * 2500mm (51” * 98.4”) |

|

Software |

Offline Software |

|

Laser Power |

150W/300W/450W |

|

Laser Source |

CO2 Glass Laser Tube |

|

Mechanical Control System |

Ball Screw & Servo Motor Drive |

|

Working Table |

Knife Blade or Honeycomb Working Table |

|

Max Speed |

1~600mm/s |

|

Acceleration Speed |

1000~3000mm/s2 |

|

Position Accuracy |

≤±0.05mm |

|

Machine Size |

3800 * 1960 * 1210mm |

|

Operating Voltage |

AC110-220V±10%,50-60HZ |

|

Cooling Mode |

Water Cooling and Protection System |

|

Working Environment |

Temperature:0—45℃ Humidity:5%—95% |

|

Package Size |

3850 * 2050 *1270mm |

|

Weight |

1000kg |

▷ Features of 1325 Laser Cutter

A Giant Leap in Productivity

◾ Stable & Excellent Cutting Quality

Constant Optical Path Design

With the optimal output optical path length, the consistent laser beam at any point in the range of the cutting table can result in an even cut through the entire material, regardless of thickness. Thanks to that, you can get a better cutting effect for acrylic or wood than the half-flying laser path.

◾ High Efficiency and Precision

Efficient Transmission System

X-axis precision screw module, Y-axis unilateral ball screw provide excellent stability and precision for the high-speed movement of the gantry. Combined with servo motor, the transmission system creates fairly high production efficiency.

◾ Durable and Long Service Life

Stable mechanical structure

The machine body is welded with a 100mm square tube and undergoes vibration aging and natural aging treatment. Gantry and cutting head use integrated aluminum. The overall configuration ensures a stable working state.

◾ High Speed Processing

High speed of cutting and engraving

Our 1300*2500mm laser cutter can achieve 1-60,000mm /min engraving speed and 1-36,000mm/min cutting speed.

At the same time, position accuracy is also guaranteed within 0.05mm, so that it can cut and engrave 1x1mm numbers or letters, totally no problem.

DIY your acrylic laser cut projects

Super Power: Large Acrylic Laser Cutter

Oversized Signage | How to Laser Cut Acrylic Sheet?

Our 300W laser cutting machine has a stable transmission structure – gear & pinion and high precision servo motor driving device, ensuring the whole laser cutting plexiglass with a continuous high quality and efficiency. We have high power 150W,300W, 450W, 600W for your laser cutting machine acrylic sheet business.

What Size of Your Acrylic Sheet?

Let's know your requirements and offer you advice!

Thick Acrylic | Laser Cut Acrylic Board

Multi-thick acrylic sheet from 10mm to 30mm can be laser cut by Flatbed Laser Cutter 130250 with optional laser power (150W, 300W, 500W).

Some Considerations During Cutting:

1. Adjust the air assist to lower the air blow and pressure to ensure the acrylic can cool down slowly

2. Choose the right lens: The thicker the material, the longer the focal length of the lens

3. Higher laser power is recommended for the thick acrylic (case by case in different demands)

Find more videos about our laser cutters at our Video Gallery

Laser Cutting Acrylic: Speed

When it comes to cutting acrylic, the most effective approach often involves using a relatively slow cutting speed paired with high laser power. This particular cutting process enables the laser beam to melt the edges of the acrylic, resulting in what can be described as a flame-polished edge.

Laser Cutting Acrylic: Speed Chart

In today's market, numerous acrylic manufacturers offer a wide array of acrylic types, including both cast and extruded variants, available in various colors, textures, and patterns. With such a diverse range of options, it's no surprise that acrylic has become an exceedingly popular choice for laser cutting and engraving. The versatility and variety of acrylic make it a favored material for creative laser projects.

Here are Some General Laser Processing Tips for Working with Acrylic:

1. Supervision is Key:

Never leave your laser machine unattended when working with acrylic. Although many materials can be susceptible to ignition, acrylic, in all its various forms, has demonstrated a higher flammability risk when cut with a laser. As a fundamental safety rule, do not operate your laser machine – regardless of the material being used – without your presence.

2. Choose the Right Acrylic:

Select the appropriate type of acrylic for your specific application. Keep in mind that cast acrylic is better suited for engraving tasks, while extruded acrylic is more suitable for laser cutting purposes.

3. Elevate the Acrylic:

To minimize backside reflection and enhance cutting quality, consider elevating the acrylic above the cutting table's surface. Accessories like Epilog's Pin Table or other support systems can be used for this purpose.

Acrylic Finishing of laser cutting

• Advertisement Displays

• Architectural Model

• Bracket

• Company Logo

• Modern Furniture

• Letters

• Outdoor Billboards

• Product Stand

• Shopfitting

• Retailer Signs

• Trophy

(acrylic laser cut earrings, acrylic laser cut signs, acrylic laser cut jewellery, acrylic laser cut letters…)

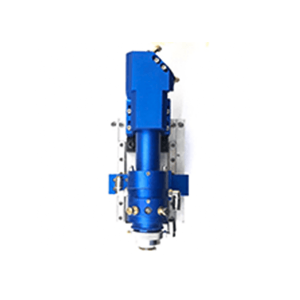

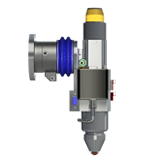

Upgrade Laser Options for you to choose

Mixed Laser Head

Auto Focus

The CCD Camera can recognize and position the pattern on the printed acrylic, assisting laser cutter to realize accurate cutting with high quality. Any customized graphic design printed can be flexibly processed along the outline with the optical system, playing an important part in advertising and other industry.

Related Acrylic Sheet Laser Cutter

for acrylic and wood laser cutting

• Fast & precise engraving for solid materials

• Two-way penetration design allows ultra-long materials placed and cut

for acrylic and wood laser engraving

• Light and compact design

• Easy to operate for beginners