Acrylic Laser Engraving Machine 130 (Laser Engraving Plexiglass/PMMA)

▶ Laser Engraving Machine for Acrylic (Small Acrylic Laser Cutting Machine)

Technical Data

|

Working Area (W *L) |

1300mm * 900mm (51.2” * 35.4 ”) |

|

Software |

Offline Software |

|

Laser Power |

100W/150W/300W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

2050mm * 1650mm * 1270mm (80.7'' * 64.9'' * 50.0'') |

|

Weight |

620kg |

(With the Acrylic Laser Engraver, You Can Laser Engrave Photo on Acrylic, Acrylic Laser Cut Shapes)

Other Upgrade Options for You to Choose

DC Brushless Motors

Servo Motors

Rotary Attachment

Auto Focus

Lifting Platform

Ball & Screw

Using the Acrylic Laser Engraver

We Make the Acrylic Tags

▷

The laser engraver for acrylic has different power options for you to choose, by setting different parameters, you can realize engraving and cutting acrylic in one machine, and in one go.

Not only for acrylic(plexiglass/PMMA), but also for other non-metals. If you are gonna expand your business by introducing other materials, the CO2 laser machine will support you. Such as wood, plastic, felt, foam, fabric, stone, leather, and so on, these materials can be cut and engraved by the laser machine. So investing in it is so cost-effective and with long-term profits.

What are you gonna make with the acrylic laser engraving and cutting machine?

Upgrade with

CCD Camera for your printed acrylic

The CCD Camera laser cutter uses advanced camera technology to precisely recognize printed patterns on acrylic sheets, allowing for accurate and seamless cutting.

This innovative acrylic laser cutter ensures that intricate designs, logos, or artwork on the acrylic are precisely replicated without any errors.

① What is CCD Camera?

② How Camera Laser Cutting Works?

CCD Camera can recognize and locate the printed pattern on the acrylic board to assist the laser with accurate cutting. Advertising board, decorations, signage, branding logos, and even memorable gifts and photos made of printed acrylic can be easily processed.

Operation Guide:

Step 1.

UV print your pattern on the acrylic sheet

Step 3.

Pick up your finished pieces

Any Questions about the Laser Engraving Machine for Acrylic?

Pictures Browse

Popular Applications of Laser Engraving Acrylic

• Advertisement Displays

• Architectural Model

• Company Labeling

• Delicate Trophies

• Modern Furniture

• Product Stand

• Retailer Signs

• Sprue Removal

• Bracket

• Shopfitting

• Cosmetic Stand

Videos - Laser Cut & Engrave Acrylic Display

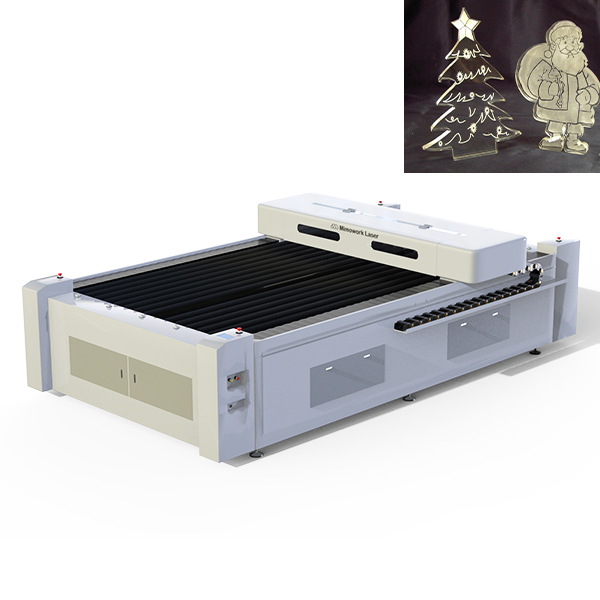

How to Laser Engrave Clear Acrylic?

→ Import your design file

→ Start the laser engraving

→ Assemble the acrylic and LED base

→ Connect to the power

Brilliant and amazing LED display is well done!

Highlights of Laser Engraved Acrylic

✔ Subtle engraved pattern with smooth lines

✔ Permanent etching mark and clean surface

✔ No need for post-polishing

What Acrylic Can be Laser Engraved?

Before you embark on experimenting with acrylic in your laser, it's essential to grasp the distinctions between the two primary types of this material: cast and extruded acrylic.

1. Cast Acrylic

Cast acrylic sheets are crafted from liquid acrylic that is poured into molds, resulting in a wide variety of shapes and sizes.

This is the type of acrylic frequently used in crafting awards and similar items.

Cast acrylic is particularly well-suited for engraving due to its characteristic of turning a frosty white color when engraved.

While it can be cut with a laser, it does not yield flame-polished edges, making it better suited for laser engraving applications.

2. Extruded Acrylic

Extruded acrylic, on the other hand, is a highly popular material for laser cutting.

It is manufactured through a high-volume production process, which often makes it more cost-effective than cast acrylic.

Extruded acrylic responds differently to the laser beam—it cuts cleanly and smoothly, and when laser cut, it produces flame-polished edges.

However, when engraved, it doesn't yield a frosted appearance; instead, you get a clear engraving.

Video Tutorial: Laser Engraving & Cutting Acrylic

Related Laser Machine for Acrylic

for acrylic and wood laser cutting

• Suitable for large format solid materials

• Cutting multi-thickness with optional power of laser tube

for acrylic and wood laser engraving

• Light and compact design

• Easy to operate for beginners

Interested in the Laser Cutting & Engraving Machine

FAQ - Acrylic Laser Engraving & Cutting

# How do you cut Acrylic Without Cracking it?

To cut acrylic without cracking it, using a CO2 laser cutter is one of the best methods. Here are some tips to achieve clean and crack-free cuts:

Use the Right Power and Speed: Adjust the power and cutting speed of the CO2 laser cutter appropriately for the thickness of the acrylic. A slow cutting speed with low power is recommended for thick acrylic, while higher power and faster speed are suitable for thinner sheets.

Ensure Proper Focus: Maintain the correct focal point of the laser beam on the surface of the acrylic. This prevents excessive heating and minimizes the risk of cracking.

Use a Honeycomb Cutting Table: Place the acrylic sheet on a honeycomb cutting table to allow smoke and heat to disperse efficiently. This prevents heat buildup and reduces the chances of cracking...

# How to Find the Focal Length of Laser?

Perfect laser cutting and engraving result means appropriate CO2 laser machine focal length.

This video answers you with specific operation steps for adjusting the CO2 laser lens to find the right focal length with a CO2 laser engraver machine.

The focus lens co2 laser concentrates the laser beam on the focus point which is the thinnest spot and has a powerful energy.

Some tips and suggestions are also mentioned in the video.

# How to Select Laser Cutting Bed for Your Production?

For different materials to be laser cut or engraved, what laser cutting machine table is the best?

1. Honeycomb Laser Cutting Bed

2. Knife Strip Laser Cutting Bed

3. Exchange Table

4. Lifting Platform

5. Conveyor Table

* For Laser Engraving Acrylic, Honeycomb Laser Bed is the Best Choice!

# How Thick of Acrylic Can a Laser Cutter Cut?

The cutting thickness of acrylic with a CO2 laser cutter depends on the power of the laser and the type of CO2 laser machine being used. Generally, a CO2 laser cutter can cut acrylic sheets ranging from a few millimeters to several centimeters in thickness.

For lower-powered CO2 laser cutters commonly used in hobbyist and small-scale applications, they can typically cut acrylic sheets up to around 6mm (1/4 inch) in thickness.

However, more powerful CO2 laser cutters, especially those used in industrial settings, can handle thicker acrylic materials. High-powered CO2 lasers can cut through acrylic sheets ranging from 12mm (1/2 inch) up to 25mm (1 inch) or even thicker.

We had a test for laser cutting thick acrylic up to 21mm with 450W laser power, the effect is beautiful. Check out the video to find more.

How to Laser Cut 21mm Thick Acrylic?

In this video, we use the 13090 laser cutting machine to cut a strip of 21mm thick acrylic. With module transmission, the high precision helps you balance between cutting speed and cutting quality.

Before starting the thick acrylic laser cutting machine, the first thing you consider is to determine the laser focus and adjust it to the appropriate position.

For thick acrylic or wood, we suggest the focus should lie in the middle of the material. Laser testing is necessary for your different materials.

# Can Laser Cut Oversized Acrylic Signage?

How to laser cut an oversized acrylic sign larger than your laser bed? The 1325 laser cutting machine(4*8 feet laser cutting machine) will be your first choice. With the pass-through laser cutter, you can laser cut an oversized acrylic sign larger than your laser bed. Laser cutting signage including wood and acrylic sheet cutting is so easy to complete.

How to Laser Cut Oversized Signage?

Our 300W laser cutting machine has a stable transmission structure – gear & pinion and high precision servo motor driving device, ensuring the whole laser cutting plexiglass with continuous high quality and efficiency.

We have high power 150W, 300W, 450W, and 600W for your laser cutting machine acrylic sheet business.

Besides laser cutting acrylic sheets, the PMMA laser cutting machine can realize elaborate laser engraving on wood and acrylic.