Laser Fabric Cutter

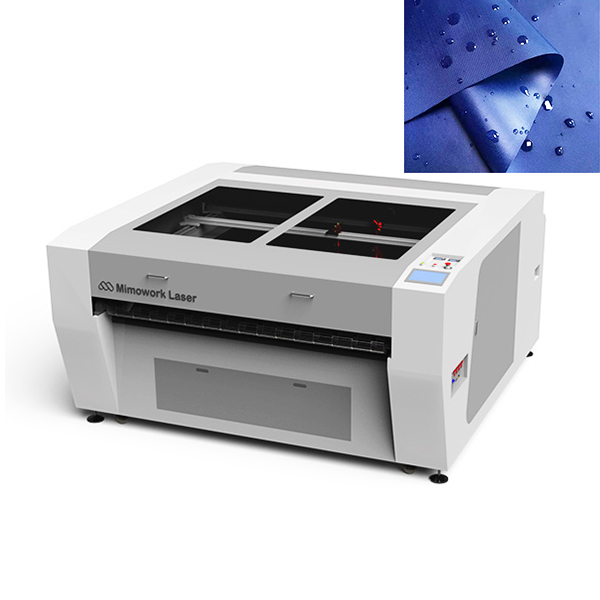

▶ Fabric laser cutting machine 160

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Servo Motor Upgrade Available

Mechanical Structure

Safe & Stable Structure

- Signal Light

Signal light can indicate the working situation and functions exerting of laser machine, helps you to do the right judgment and operation.

- Emergency Button

Happen to some sudden and unexpected condition, the emergency button will be your safety guarantee by stopping the machine at once. Safe production is always the first code.

- Safe Circuit

Smooth operation makes a requirement for the function-well circuit, whose safety is the premise of safety production. All electrical components are installed strictly according to CE standards.

- Enclosed Design

Higher level of safety and convenience! Taking the varieties of fabrics and working environment into account, we design the enclosed structure for the clients with specific requirements. You can check out the cutting condition through the acrylic window, or timely monitor it by the computer.

Customized Production

The flexible laser cutter can easily cut versatile design patterns and shapes with perfect curve cutting. Whether for customized or mass production, Mimo-cut provides technology support for cutting instructions after uploading design files.

— Optional working table types: conveyor table, fixed table (knife strip table, honey comb table)

— Optional working table sizes: 1600mm * 1000mm, 1800mm * 1000mm, 1600mm * 3000mm

• Meet varied demands for coiled fabric, pieced fabric and different formats.

High-automation

With the aid of the exhaust fan, the fabric can be fastened on the working table by strong suction. That makes the fabric remain flat and stable to realize accurate cutting without manual and tool fixes.

Conveyor table is very fit for the coiled fabric, providing great convenience for materials auto-conveying and cutting. Also with the aid of an auto-feeder, the whole workflow can be connected smoothly.

R&D for Flexible Material Cutting

Samples of Laser Cutting Fabric

Video Display

Find more videos about our laser cutters at our Video Gallery

Denim Textiles Laser Cutting

◆ No pull deformation with contactless processing

◆ Crisp & clean edge without burr

◆ Flexible cutting for any shapes and sizes

Laser Cutting Plaid Shirt, Blouse

Pictures Browse

What is the Best Laser for Cutting Fabric?

Both fiber and CO2 lasers can cut through fabric, but why do we barely see anyone use fiber lasers to cut fabric?

CO2 Laser:

The primary reason for using CO2 lasers for fabric cutting is that they are well-suited to materials that absorb the 10.6-micrometer wavelength of CO2 laser light.

This wavelength is effective for vaporizing or melting the fabric without causing excessive charring or burning.

CO2 lasers are often used for cutting natural fabrics like cotton, silk, and wool. They are also suitable for synthetic fabrics such as polyester and nylon.

Fiber Laser:

Fiber lasers are known for their high energy density and are often used for cutting metals and other materials that have high thermal conductivity. Fiber lasers operate at a wavelength of around 1.06 micrometers, which is less absorbed by fabric compared to CO2 lasers.

This means they may not be as efficient for cutting some types of fabric and may require higher power levels.

Fiber lasers can be used for cutting thin or delicate fabrics, but they may produce more heat-affected zones or charring compared to CO2 lasers.

In Conclusion:

CO2 lasers typically have a longer wavelength compared to fiber lasers, making them better for cutting thicker fabrics and materials with lower thermal conductivity. They are capable of producing high-quality cuts with smooth edges, which is essential for many textile applications.

If you primarily work with textiles and require clean, precise cuts on a variety of fabrics, a CO2 laser is generally the most suitable choice. CO2 lasers are better suited for fabrics due to their wavelength and ability to provide clean cuts with minimal charring. Fiber lasers can be used for fabric cutting in specific situations but are not as commonly employed for this purpose.

Related Fabric Cutter Laser

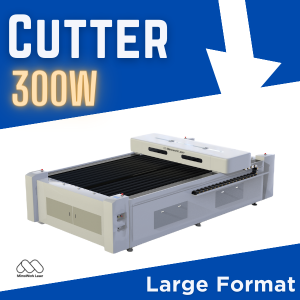

• Laser Power: 100W / 150W / 300W

• Working Area (W *L): 1600mm * 1000mm

• Collecting Area (W *L): 1600mm * 500mm

• Laser Power: 100W/150W/300W

• Working Area (W *L): 1800mm * 1000mm

• Laser Power: 150W/300W/500W

• Working Area (W *L): 1600mm * 3000mm