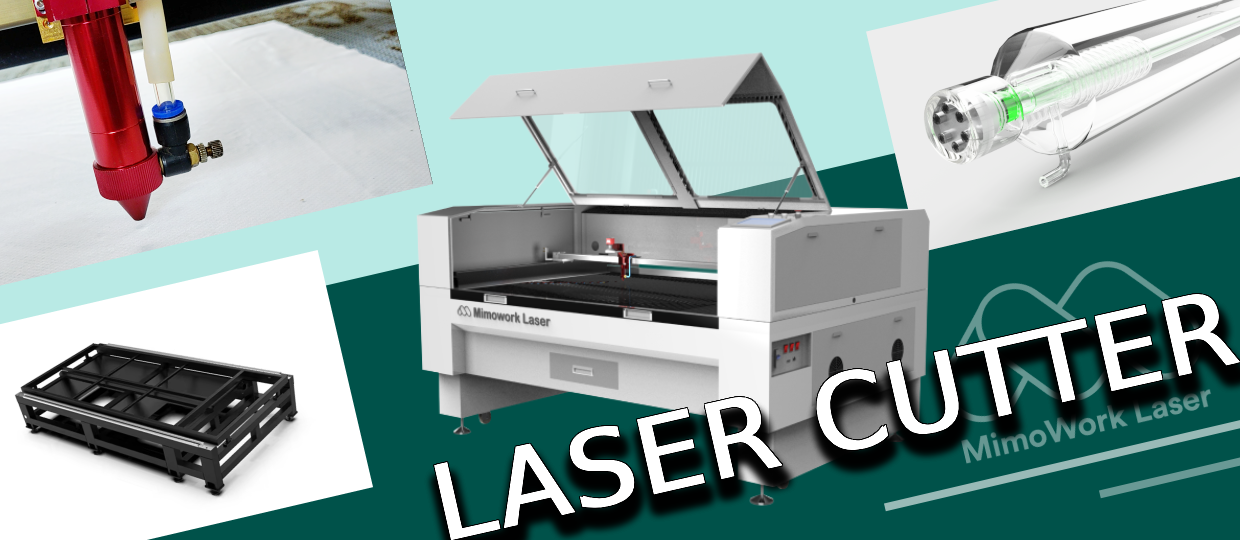

Laser Foam Cutter for Small Business and Industrial Use

▶ MimoWork Laser Foam Cutting Machine

Technical Data

|

Model |

Working Table Size (W * L) |

Laser Power |

Machine Size (W*L*H) |

|

F-1060 |

1000mm * 600mm |

60W/80W/100W |

1700mm*1150mm*1200mm |

|

F-1390 |

1300mm * 900mm |

80W/100W/130W/150W/300W |

1900mm*1450mm*1200mm |

|

F-1325 |

1300mm * 2500mm |

150W/300W/450W/600W |

2050mm*3555mm*1130mm |

Customized Machine Sizes can be available

If you need more configurations and parameters about the foam laser cutter, please email us to discuss them further with our laser expert. (email: info@mimowork.com)

The bed frame is welded using thick square tubes and reinforced internally to enhance structural strength and tensile resistance. It undergoes high-temperature annealing and natural aging treatment to eliminate welding stress, prevent deformation, reduce vibrations, and ensure excellent cutting precision.

The enclosed design of the CO2 laser cutting machine enhances safety, efficiency, and usability during foam cutting operations. This thoughtfully engineered structure surrounds the working area, creating a secure environment for operators and protecting against potential hazards.

The CNC (Computer Numerical Control) system is the brain behind the CO2 laser cutting machine, ensuring precise and automated operation during the foam cutting process. Designed for efficiency and reliability, this advanced system allows seamless coordination between the laser source, cutting head, and motion control components.

The enclosed design of the CO2 laser cutting machine enhances safety, efficiency, and usability during foam cutting operations. This thoughtfully engineered structure surrounds the working area, creating a secure environment for operators and protecting against potential hazards.

◼ Honeycomb Laser Cutting Bed

The honeycomb laser cutting bed supports a wide range of materials while allowing the laser beam to pass through the workpiece with minimal reflection, ensuring the material surfaces are clean and intact.

The honeycomb structure provides excellent airflow during cutting and engraving, which helps prevent the material from overheating, reduces the risk of burn marks on the underside of the workpiece, and effectively removes smoke and debris.

We recommend the honeycomb table for cardboard laser cutting machine, for your high degree of quality and consistency in laser-cut projects.

◼ Well-Performed Exhaust System

All MimoWork Laser Machines are equipped with a well-performed Exhaust System, including the cardboard laser cutting machine. When laser cutting cardboard or other paper products, the smoke and fume produced will be absorbed by the exhaust system and discharged to the outside. Based on the size and power of the laser machine, the exhaust system is customized in ventilation volume and speed, to maximize the great cutting effect.

If you have higher requirements for the cleanliness and safety of the working environment, we have a upgraded ventilation solution - a fume extractor.

◼ Industrial Water Chiller

The water chiller is a vital component of the CO2 laser cutting machine, ensuring the laser tube operates at optimal temperature during foam cutting processes. By efficiently regulating heat, the water chiller prolongs the lifespan of the laser tube and maintains stable cutting performance, even during extended or high-intensity operations.

• Efficient Cooling Performance

• Precise Temperature Control

• User-Friendly Interface

• Compact and Space-Saving

◼ Air Assist Pump

This air assist for laser machine directs a focused stream of air onto the cutting area, which is designed to optimize your cutting and engraving tasks, especially when working with materials like cardboard.

For one thing, the air assist for the laser cutter can effectively clear away the smoke, debris, and vaporized particles during laser cutting cardboard or other materials, ensuring a clean and precise cut.

Additionally, the air assist reduces the risk of material scorching and minimizes the chances of fire, making your cutting and engraving operations safer and more efficient.

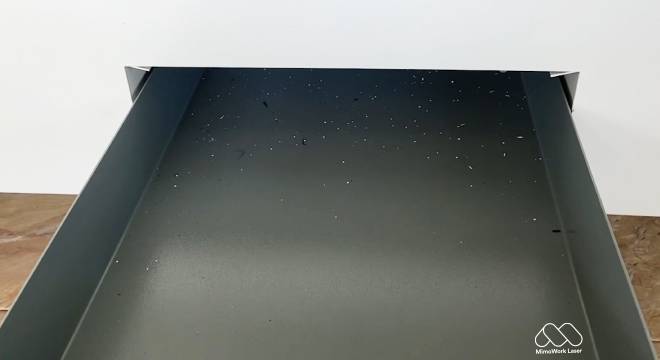

◼ Dust Collection Compartment

The dust collection area is located below the honeycomb laser cutting table, designed for collecting the finished pieces of laser cutting, waste, and fragment dropping from the cutting area. After laser cutting, you can open the drawer, take out the waste, and clean the inside. It's more convenient for cleaning, and significant for next laser cutting and engraving.

If there is debris left on the working table, the material to be cut will be contaminated.

▶ Upgrade Your Foam Production into Top Level

Advanced Options of the Laser Cutter

Servo Motors

Brushless DC Motors

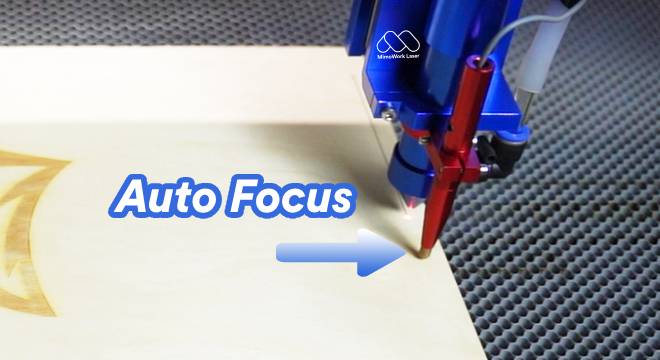

Auto Focus Device

Select Suitable Laser Configurations to Improve Your Production

Video: Laser Cutting Thick Foam (up to 20mm)

Related Laser Foam Cutting Machine

• Working Area: 1000mm * 600mm

• Laser Power: 40W/60W/80W/100W

• Max Cutting Speed: 400mm/s

• Drive System: Step Motor Belt Control

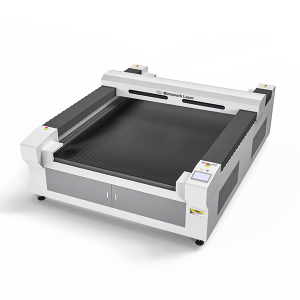

• Working Area: 1600mm * 1000mm

• Collecting Area: 1600mm * 500mm

• Laser Power: 100W / 150W / 300W

• Max Cutting Speed: 400mm/s

• Drive System: Belt Transmission & Step Motor Drive / Servo Motor Drive

• Working Area: 1300mm * 2500mm

• Laser Power: 150W/300W/450W

• Max Cutting Speed: 600mm/s

• Drive System: Ball Screw & Servo Motor Drive