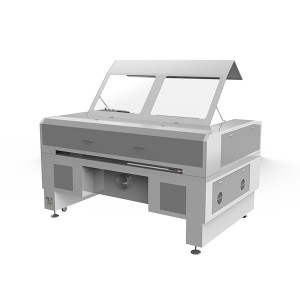

MDF Laser Cutter

▶ MDF wood laser cutter and laser engraver

Technical Data

|

Working Area (W *L) |

1300mm * 900mm (51.2” * 35.4 ”) |

|

Software |

Offline Software |

|

Laser Power |

100W/150W/300W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

2050mm * 1650mm * 1270mm (80.7'' * 64.9'' * 50.0'') |

|

Weight |

620kg |

Multifunction in One Machine

Vacuum Table

Two-way Penetration Design

Stable and Safe Structure

◾ Adjustable Air Assist

Air assist can blow the debris and chippings from the surface of wood, and protect the MDF from scorching during laser cutting and engraving. Compressed air from the air pump is delivered into the carved lines and incision through the nozzle, clearing the extra heat gathered on the depth. If you want to achieve burning and darkness vision, adjust the pressure and size of airflow for your desire. Any questions to consult us if you are confused about that.

◾ Exhaust Fan

The lingering gas can be absorbed into the exhaust fan to eliminate the smoke bothering the MDF and laser cutting. Downdraft ventilation system cooperated with fume filter can bring out the waste gas and clean the processing environment.

◾ Signal Light

Signal light can indicate the working situation and functions exerting of laser machine, helps you to do the right judgment and operation.

◾ Emergency Button

Happen to some sudden and unexpected condition, the emergency button will be your safety guarantee by stopping the machine at once.

◾ Safe Circuit

Smooth operation makes a requirement for the function-well circuit, whose safety is the premise of safety production.

◾ CE Certification

Owning the legal right of marketing and distributing, MimoWork Laser Machine has been proud of the solid and reliable quality.

▶ MimoWork Laser options contributes to your mdf laser cut projects

Upgrade options for you to choose

Auto Focus

CCD Camera

Mixed Laser Head

Ball & Screw

Motors

DC Brushless Motor

Servo Motor

(MDF Laser Cut Letters, MDF Laser Cut Names, MDF Laser Cut Terrain)

MDF Samples of Laser Cutting

Pictures Browse

• Grill MDF Panel

• MDF Box

• Photo Frame

• Carousel

• Helicopter

• Terrain Templates

• Furniture

• Flooring

• Veneer

• Miniature Buildings

• Wargaming Terrain

• MDF Board

Other Wood Materials

— laser cutting and engraving wood

Bamboo, Balsa Wood, Beech, Cherry, Chipboard, Cork, Hardwood, Laminated Wood, Multiplex, Natural Wood, Oak, Plywood, Solid Wood, Timber, Teak, Veneers, Walnut…

Any questions about laser cutting & laser engraving MDF

Laser Cutting MDF: Achieve Optimality

To achieve optimal results in both cutting and engraving medium-density fiberboard (MDF), it's essential to understand the laser processes and adjust various parameters accordingly.

Laser cutting involves the use of a high-power CO2 laser, typically around 100 W, delivered through an X-Y scanned laser head. This process enables efficient single-pass cutting of MDF sheets with thicknesses ranging from 3 mm to 10 mm. For thicker MDF (12 mm and 18 mm), multiple passes may be necessary. The laser light vaporizes and removes material as it moves along, resulting in precise cuts.

On the other hand, laser engraving employs lower laser power and refined feed rates to partially penetrate the material's depth. This controlled approach allows for the creation of intricate 2D and 3D reliefs within the MDF thickness. While lower-power CO2 lasers can yield excellent engraving results, they have limitations in terms of single-pass cut depth.

In the quest for optimal results, factors like laser power, feed speed, and focal length must be carefully considered. The choice of focal length is particularly crucial, as it directly impacts the spot size on the material. Shorter focal length optics (around 38 mm) produce a small-diameter spot, ideal for high-resolution engraving and fast cutting but suitable mainly for thin materials (up to 3 mm). Deeper cuts with shorter focal lengths may result in non-parallel sides.

In the quest for optimal results, factors like laser power, feed speed, and focal length must be carefully considered. The choice of focal length is particularly crucial, as it directly impacts the spot size on the material. Shorter focal length optics (around 38 mm) produce a small-diameter spot, ideal for high-resolution engraving and fast cutting but suitable mainly for thin materials (up to 3 mm). Deeper cuts with shorter focal lengths may result in non-parallel sides.

In Summary

Achieving the best outcomes in MDF cutting and engraving necessitates a nuanced understanding of laser processes and meticulous adjustment of laser settings based on the MDF type and thickness.

MDF Laser Cut Machine

for wood and acrylic laser cutting

• Suitable for large format solid materials

• Cutting multi-thickness with optional power of laser tube

for wood and acrylic laser engraving

• Light and compact design

• Easy to operate for beginners