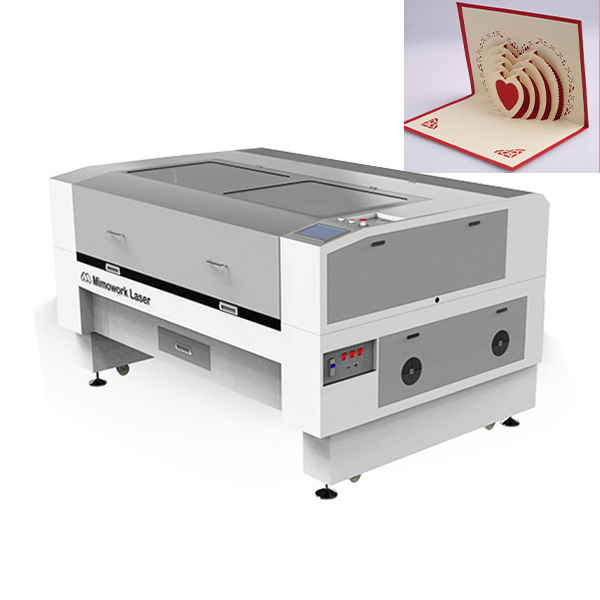

Small Laser Paper Cutter

▶ laser paper cutter machine (both paper engraving and cutting)

Technical Data

|

Working Area (W *L) |

1000mm * 600mm (39.3” * 23.6 ”) 1300mm * 900mm(51.2” * 35.4 ”) 1600mm * 1000mm(62.9” * 39.3 ”) <Customized Table Sizes Available> |

|

Software |

Offline Software |

|

Laser Power |

40W/60W/80W/100W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

1750mm * 1350mm * 1270mm |

|

Weight |

385kg |

Structure Features

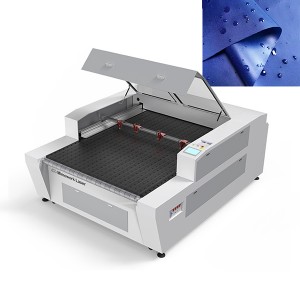

◼ Vacuum Table

The vacuum table can fix the paper on the honey comb table especially for some thin paper with wrinkles. Strong suction pressure from the vacuum table can guarantee the materials remain flat and stable to realize accurate cutting. For some corrugated paper like cardboard, you can put some magnets attached to the metal table to further fix materials.

◼ Air Assist

Air assist can blow the smoke and debris from the surface of the paper, bringing a relatively safe cutting finish without excessive burning. Also, the residue and accumulative smoke block out the laser beam through the paper, whose harm is especially obvious on cutting the thick paper, like cardboard, so proper air pressure need to be set to get rid of the smoke while not blowing them back to the paper surface.

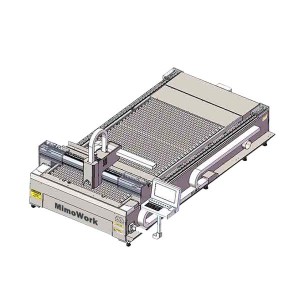

▶ laser paper cutter machine (both laser paper engraving and cutting))

Upgrade Options for you to choose

Servo Motors

Brushless DC Motors

Customized A Laser Solution to Boost Your Paper Business

(laser cut invitation, laser cut crafts, laser cut cardboard)

What is Your Requirement?

• Invitation Card

• 3D Greeting Card

• Window Stickers

• Package

• Model

• Brochure

• Business Card

• Hanger Tag

• Scrap Booking

• Lightbox

Special Applications for Paper Laser Cutting

▶ Kiss Cutting

Different from laser cutting, engraving, and marking on paper, kiss cutting adopts a part-cutting method to create dimensional effects and patterns like laser engraving. Cut the top cover, the color of the second layer will appear. More information to check out the page: What is CO2 Laser Kiss Cutting?

▶ Printed Paper

For the printed and patterned paper, accurate pattern cutting is necessary to achieve a premium visual effect. With the assist of the CCD Camera, Galvo Laser Marker can recognize and position the pattern and strictly cut along the contour.

Check out the videos >>

Fast Laser Engraving Invitation Card

Laser Cut Multi-layer Paper

What is Your Paper Idea?

Let the Paper Laser Cutter Help You!

Related Laser Paper Cutter Machine

• CCD camera laser cutter - Custom laser cutting paper

• Compact and small machine size

MimoWork Laser Provides!

Professional and affordable paper laser cutter

FAQ - Y'all Got Questions, We Got Answers

1. Which Cardboard Type is Suitable for Laser Cutting?

Corrugated cardboard stands out as the preferred choice for laser-cutting projects demanding structural integrity. It offers affordability, is available in diverse sizes and thicknesses, and is amenable to effortless laser cutting and engraving. A frequently used variety of corrugated cardboard for laser cutting is the 2-mm-thick single-wall, double-face board.

Laser Cut Cardboard to Make A Cat House

2. Is There a Paper Type Unsuitable for Laser Cutting?

Indeed, excessively thin paper, such as tissue paper, cannot be laser-cut. This paper is highly susceptible to burning or curling under the heat of a laser. Additionally, thermal paper is not advisable for laser cutting due to its propensity to change color when subjected to heat. In most cases, corrugated cardboard or cardstock is the preferred choice for laser cutting.

3. Can you Laser Engrave Cardstock?

Certainly, cardstock can be laser engraved. It's crucial to carefully adjust the laser power to avoid burning through the material. Laser engraving on colored cardstock can yield high-contrast results, enhancing the visibility of the engraved areas.