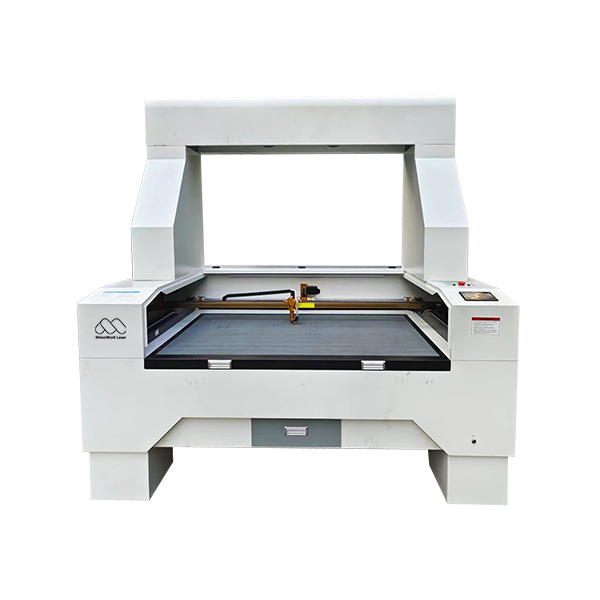

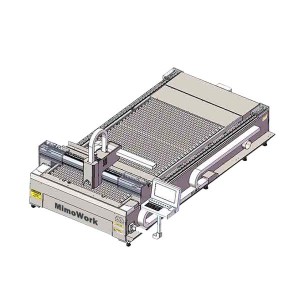

Laser Cutter & Engraver with Projector

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”)1600mm * 1000mm (62.9” * 39.3 ”)

(customized working area) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

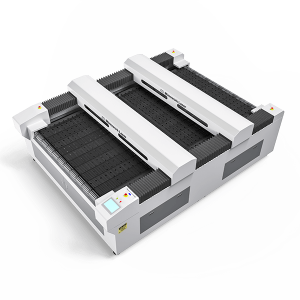

* Multiple laser heads can be customized

▶ FYI: The Flatbed Laser Cutter Machine 130 is suitable to cut and engrave on solid materials such as acrylic and wood. Honey comb working table and knife strip cutting table can carry the materials and help to reach best the cutting effect without dust and fume that can be sucked into and purified.

Video of Laser Cutting Leather Uppers

Find more videos about our laser cutters at our Video Gallery

Projector Positioning - laser cutting & engraving

✔ Easy to place the workpiece in the right area

✔ High-precision cutting and engraving based on preview graphic

✔ Non-contact laser processing - clean edge and surface

Proper and right laser power guarantees heat energy uniformly melts through leather pieces. Fine laser beam leads to precise laser cutting holes and engraving, creating unique leather designs. The projector laser cutter is the ideal tool to process leather.

Unique advantages of laser cutting signs & decorations

✔ Clean and smooth edges with thermal melting when processing

✔ No limitation on shape, size, and pattern realizes flexible customization

✔ Customized laser tables meet requirements for varieties of materials formats

Crystal surface and exquisite engraving details

✔ Bringing about more economical and environment-friendly manufacturing process

✔ Customized patterns can be engraved whether for pixel and vector graphic files

✔ Quick response to market from samples to large-lot production