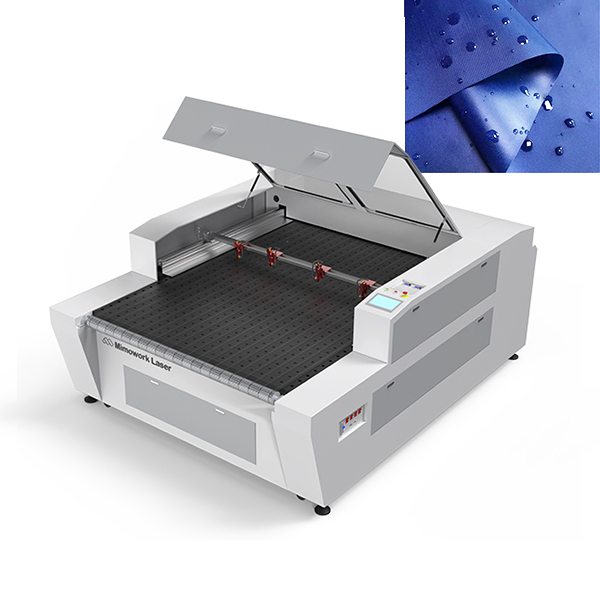

Textile Laser Cutting Machine

▶ Textile Laser Cutter Machine

Technical Data

| Working Area (W * L) | 1800mm * 1000mm (70.9” * 39.3 ”) Working Area can be Customized |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Multiple Laser Heads option available

* Customized Working Format available

Mechanical Structure

◼ High Automation

Works together with the feeding system without human intervention. The whole cutting process is continuous, accurate and with high quality. Fast and more fabric production like apparel, home textile, functional gear is easy to fulfill. One fabric laser cutting machine can replace 3~5 labors that saves lots of costs. (Easy to get 500 sets of digitally printed garments with 6 pieces in an 8-hour shift.)

MimoWork laser machine comes with two exhaust fans, one is the upper exhaust and the other is the lower exhaust. The exhaust fan can not only keep the feeding fabrics stuck still on the conveyor working table but also get you away from the possible smoke and dust, making sure that the indoor environment is always clean and nice.

◼ Customized Production

— Optional working table types: conveyor table, fixed table (knife strip table, honey comb table)

— Optional working table sizes: 1600mm * 1000mm, 1800mm * 1000mm, 1600mm * 3000mm

• Meet varied demands for coiled fabric, pieced fabric and different formats.

Customize your design, Mimo-Cut software will instruct the right laser cutting on fabric. MimoWork cutting software is developed to be closer to our client's needs, more user-friendly, and more compatible with our machines.

◼ Safe & Stable Structure

- Signal Light

You can monitor the laser cutter status directly, helping to track productivity and avert danger.

- Emergency Button

The emergency button is intended to provide you with a high-quality safeguarding component for your laser machine. It features a simplistic, yet straightforward design that can be easily operated, greatly adding safety measures.

- Safe Circuit

Superior electronic component. It is anti-rust and corrosion-resistant as its powder-coated surface promises longer-term usage. Make sure the operation stability.

- Extension Table

The extension table is convenient for collecting fabric being cut, especially for some small fabric pieces like plush toys. After cutting, these fabrics can be conveyed to the collection area, eliminating manual collecting.

Upgrade Options you can choose

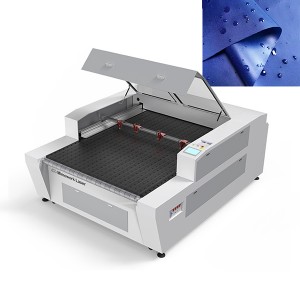

Two Laser Heads - Option

Automatic Laser Fabric Cutter Boosts Your Production, Saves Labor Costs

(laser cutting for fashion and textiles)

Fabric Samples

Pictures Browse

Video Display

How to cut cotton fabric with laser cutter

Brief steps are below:

1. Upload the garment graphic file

2. Auto-feed the cotton fabric

3. Start laser cutting

4. Collect

Material Overview

More Fabrics you can laser cut:

• Cordura • Polyester • Denim • Felt • Canvas • Foam • Brushed Fabric • Non-woven • Nylon • Silk • Spandex • Spacer Fabric • Synthetic Fabric • Leather • Insulation Material

The choice between a CO2 laser and a CNC oscillating knife cutting machine for textile cutting depends on your specific needs, the type of textiles you work with, and your production requirements. Both machines have their advantages and disadvantages, so let's compare them to help you make an informed decision:

CO2 Laser Cutting Machine:

1. Precision:

CO2 lasers offer high precision and can cut intricate designs and patterns with fine details. They produce clean, sealed edges, which is important for certain applications.

CNC Oscillating Knife Cutting Machine:

1. Material Compatibility:

CNC oscillating knife machines are well-suited for cutting a wide variety of materials, including textiles, foams, and flexible plastics. They are particularly suitable for thick and rigid materials.

2. Versatility:

CO2 lasers can cut a wide range of fabrics, both natural and synthetic, including delicate materials like silk and lace. They are also suitable for cutting synthetic materials and leather.

2. Versatility:

While they may not offer the same level of precision for intricate designs as CO2 lasers, CNC oscillating knife machines are versatile and can be used for a range of cutting and trimming applications.

3. Speed:

CO2 lasers are generally faster than CNC oscillating knife-cutting machines for certain textile applications, especially when cutting complex shapes with a single layer each time. The actual cutting speed can reach 300mm/s to 500mm/s when laser-cut textiles.

3. Lower Maintenance:

CNC oscillating knife machines often require less maintenance than CO2 lasers since they don't have laser tubes, mirrors, or optics that need cleaning and alignment. But you need to change knives every few hours for the best cutting results.

4. Minimal Fraying:

CO2 lasers minimize fraying and unraveling of fabric edges due to the heat-affected zone being relatively small.

4. No Heat-Affected Zone:

CNC knife cutters do not generate a heat-affected zone, so there is no risk of fabric distortion or melting.

5. No Tool Changes:

Unlike CNC oscillating knife machines, CO2 lasers do not require tool changes, making them more efficient for handling a variety of cutting tasks.

5. Clean Cuts:

For many textiles, CNC oscillating knives can produce cleaner cuts with minimal risk of burning or charring compared to CO2 lasers.

CNC vs Laser | The Efficiency Showdown

In this video, we revealed the game-changing strategies that will skyrocket your machine's efficiency, propelling it to outshine even the most formidable CNC cutters in the realm of fabric cutting.

Get ready to witness a revolution in cutting-edge technology as we unlock the secrets to dominating the CNC vs. laser landscape.

In Summary, Here are Some Considerations to Help you Decide:

1. Material Compatibility:

If you primarily work with delicate fabrics and require high precision for intricate designs, the additional added value is what you are looking for, a CO2 laser may be the better choice.

2. Mass Production:

If you want to cut multiple layers at one time for mass production with low requirements on clean edges, a CNC oscillating knife cutter may be more versatile.

3. Budget and Maintenance:

Budget and maintenance requirements also play a role in your decision. Smaller, entry-level CNC oscillating knife-cutting machines can start at around $10,000 to $20,000. Larger, industrial-grade CNC oscillating knife-cutting machines with advanced automation and customization options can range from $50,000 to several hundred thousand dollars. These machines are suitable for large-scale production and can handle heavy-duty cutting tasks. The textile laser cutting machine costs much less than this.

Making Decisions - CO2 Laser or CNC

Ultimately, the choice between a CO2 laser and a CNC oscillating knife cutting machine for textile cutting should be based on your specific needs, production requirements, and the types of materials you handle.

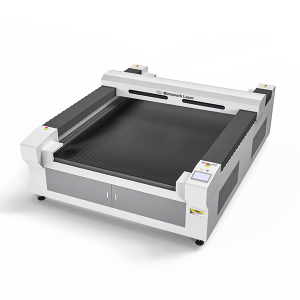

More Choices - Fabric Laser Cutters

• Laser Power: 100W/150W/300W

• Working Area (W *L): 1600mm * 1000mm

• Collecting Area (W *L): 1600mm * 500mm

• Laser Power: 150W/300W/450W

• Working Area (W *L): 1600mm * 3000mm