CO2 Galvo Laser Engraver for Leather Engraving & Perforating

▶ Leather laser engraving machine for customization & batch production

Technical Data

| Working Area (W * L) | 400mm * 400mm (15.7” * 15.7”) |

| Beam Delivery | 3D Galvanometer |

| Laser Power | 180W/250W/500W |

| Laser Source | CO2 RF Metal Laser Tube |

| Mechanical System | Servo Driven, Belt Driven |

| Working Table | Honey Comb Working Table |

| Max Cutting Speed | 1~1000mm/s |

| Max Marking Speed | 1~10,000mm/s |

Structure Features - Leather Laser Engraver

RF Metal Laser Tube

Galvo Laser Marker adopts RF (Radio Frequency) metal laser tube to meet higher engraving and marking precision. With a smaller laser spot size, intricate pattern engraving with more details, and fine holes perforating can be easily realized for leather products while speedy efficiency. High quality and long service life are the remarkable features of the metal laser tube. Besides that, MimoWork provides DC (direct current) glass laser tube to choose which is roughly 10% of the price of an RF laser tube. Pick up your suitable configuration as production demands.

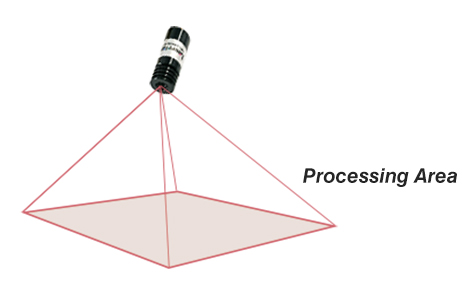

Red-light indication System

identify the processing area

Galvo Laser Lens

Galvo Laser Head

Higher Efficiency - faster speed

Rotary Plate

X-Y Moving Table

Any Questions about Galvo Laser Engraver Configurations?

(Various Applications of Laser Engraving Leather)

Samples From the Leather Laser Engraving

How to choose engraving tools for leather craft?

From vintage leather stamping and leather carving to new tech trending: leather laser engraving, you always enjoy leather crafting and trying new something to rich and refine your leather work. Open your creativity, let the leather crafts ideas run wild, and prototype your designs.

DIY some leather projects like leather wallets, leather hanging decorations, and leather bracelets, and on a higher level, you can use leather working tools like laser engraver, die cutter, and laser cutter to start your leather craft business. It’s crucial to upgrade your processing methods.

LEATHER CRAFT: Laser Engraving Leather!

Video Display: Laser Engraving & Cutting Leather Shoes

Can you Laser Engrave on Leather?

Laser marking on leather is a precise and versatile process used to create permanent marks, logos, designs, and serial numbers on leather goods such as wallets, belts, bags, and footwear.

Laser marking provides high-quality, intricate, and durable results with minimal material distortion. It's widely used in the fashion, automotive, and manufacturing industries for customization and branding purposes, enhancing product value and aesthetics.

The laser's ability to achieve fine details and consistent results makes it an excellent choice for leather marking applications. Leather suitable for laser engraving typically includes various types of genuine and natural leathers, as well as some synthetic leather alternatives.

The Best Types of Leather for Laser Engraving Include:

1. Vegetable-Tanned Leather:

Vegetable-tanned leather is a natural and untreated leather that engraves well with lasers. It produces a clean and precise engraving, making it suitable for a wide range of applications.

2. Full-Grain Leather:

Full-grain leather is known for its natural grain and texture, which can add character to laser-engraved designs. It engraves beautifully, especially when highlighting the grain.

3. Top-Grain Leather:

Top-grain leather, often used in high-end leather products, also engraves well. It's smoother and more uniform than full-grain leather, providing a different aesthetic.

4. Aniline Leather:

Aniline leather, which is dyed but not coated, is suitable for laser engraving. It maintains a soft and natural feel after engraving.

5. Nubuck and Suede:

These leathers have a unique texture, and laser engraving can create interesting contrast and visual effects.

6. Synthetic Leather:

Some synthetic leather materials, like polyurethane (PU) or polyvinyl chloride (PVC), can also be laser engraved, although results may vary depending on the specific material.

When choosing leather for laser engraving, it's essential to consider factors such as the leather's thickness, finish, and intended application. Additionally, performing test engravings on a sample piece of the specific leather you plan to use can help determine the optimal laser settings for the desired results.

Why Choose Galvo Laser to Engrave Leather

▶ High Speed

Flying marking from dynamic mirror deflection wins out in processing speed compared with flatbed lase machine. There is no mechanical movement during processing (with the exception of the mirrors), the laser beam can be guided over the workpiece at an extremely high speed.

▶ Intricate Marking

Smaller the laser spot size, higher precision of laser engraving and marking. Custom leather laser engraving on some leather gifts, wallets, crafts can be realized by the glavo laser machine.

▶ Multi-purpose in one step

Continuous laser engraving and cutting, or perforating and cutting on one step save processing time and eliminate unnecessary tool replacement. For premium processing effect, you can choose different laser powers to meet specific processing technic. Inquire us for any questions.

What is Galvo Laser? How it Works?

For the galvo scanner laser engraver, the secret of fast engraving, marking, and perforating lies in the galvo laser head. You can see the two deflectable mirrors which are controlled by two motors, the ingenious design can transmit the laser beams while controlling the movement of laser light. Nowadays there has been auto focusing galvo head master laser, its fast speed and automation will greatly expand your production volume.

![3D Laser Series [For Subsurface Laser Engraving]](https://cdnus.globalso.com/mimowork/3d-laser-series-high-end-1-300x300.png)