Laser Welding vs TIG Welding: He aha ka mea i hoʻololi i 2024

He aha ka Handheld Laser Welding?

Kuʻi lima lima lima ʻole

Kuʻi lima lima limahoʻohana i ka mīkini laser lawe lima e hoʻohui i nā mea, maʻamau me nā metala.

Hiki i ka welding laser lima lima nonui akuka maneuverability a me ka pololei,

A hana i kahi kiʻekiʻe, maʻemaʻe weld meliʻiliʻihookomo wela,

Hoemi anadistortion a me ka pono no ka hana nui ma hope o ka weld.

Hiki i nā mea hana ke hoʻololi maʻalahi i ka mana a me ka wikiwiki o ka laser,

E hoʻāhoʻonohonoho i hoʻonohonoho ʻiano nā mea like ʻole a me nā mānoanoa.

Papa maʻiʻo:

He aha ka Laser Weld Cleaning?

Ka Pono o ka Maemae ma ka Welding

ʻO ka hoʻomaʻemaʻe mua ʻana no ka welding TIG

I ka pili ana i ka wiliwili,

He kuleana koʻikoʻi ka maʻemaʻe i ka hoʻokōkūlana kiʻekiʻehopena.

Pili kēia loina i ka welding TIG a me ka welding laser paʻa lima,

Akā ʻokoʻa nā ʻano o ka hoʻomākaukau ʻana i ka mea.

No kēlā me kēia kaʻina hana wiliwili,

ʻO ka loaʻa ʻana o nā mea haumia e like me ka ʻōpala, ka pena, a me ka momona

Hikikoʻikoʻi koʻikoʻika pono o ka weld.

Hiki i kēia mau haumia ke alakaʻi i nā hono nāwaliwali, porosity, a me nā hemahema ʻē aʻe

Hoʻopilikia kēia i ka ikaika o ka huahana hope.

Penei ʻoePonoE hana me kēia mau Contaminants:Hoomaemae Weld Laser.

Hoʻomaʻemaʻe Laser Weld vs TIG Welding: Laser Weld Cleaning

Hana ʻia nā ʻili i hoʻomaʻemaʻe ʻia i nā welika kiʻekiʻe

Hoʻomaʻemaʻe Laser Weld no ka holoi lima lima lima

ʻOiai ke hilinaʻi nei ka welding TIGmanualnā ʻano hoʻomaʻemaʻe e like me ka angle grinding a me ka holoi ʻana i ka acetone,

Hāʻawi ʻia ka welding laser paʻa i kahi mea hou akuoluolu'ē aʻe me kona hiki ke hoʻomaʻemaʻe hui.

ʻAʻole hoʻonui kēia hana hou i ka pono

Akā, e hōʻoiaʻiʻo i ka maikaʻi o ke kaʻina hana welding e like me ka hiki,

Ke alakaʻi nei i nā hopena maikaʻi aʻe.

Hoʻomākaukau ʻia ʻo TIG welding:

I TIG (ʻO ke kinoea inert ʻo Tungsten) welding, meticulous hoomakaukau pono.

Ma mua o ka hoʻomaka ʻana i ke kaʻina hana welding,

He mea maʻamau ka hoʻohananā mea wili kihie wehe i ka ʻōpala a i ʻole nā palapala mai ka ʻili o ka mea.

ʻO kēia hoʻomaʻemaʻe mechanical e kōkua i ka hoʻomaʻemaʻe ʻana i ka ʻili mai nā haumia.

Ma hope o kēia, holoi pono ʻia meacetonehana maʻamau.

ʻO ka Acetone kahi mea hoʻoheheʻe ikaikawehe ponoʻO ka momona a i ʻole nā mea haumia i koe,

Ke waiho nei i kahi maʻemaʻe no ka weld.

ʻO kēia kaʻina hana hoʻomaʻemaʻe ʻelua hiki ke hoʻopau i ka manawa,

Akā he mea nui ia no ka loaʻa ʻana o kahi weld ikaika a paʻa.

Hoʻomākaukau ʻia ʻo Laser Weld

ʻO ka ʻokoʻa, hāʻawi ʻia ka welding laser paʻa lima

He mea hou akuhoʻopololei ʻiai ka hoʻomākaukau ʻana i luna.

Me a3-i-1welder laser, e maʻalahi ke kaʻina hana.

Hoʻolako pinepine ʻia kēia mau mīkini holomuanā nozzles hiki ke hoʻololi

ʻAe kēia no ka hoʻomaʻemaʻe ʻana i ka ʻili ma mua o ka wili ʻana.

ʻAʻole like me nā hana kuʻuna, kahi e pono ai nā mea hana kaʻawale a me nā mea hoʻomaʻemaʻe.

Hiki i nā mea welder laser ke hoʻomaʻemaʻe maʻalahi i ka ʻili me kahi kukuna laser kikoʻī.

ʻAʻole wale kēia e mālama i ka manawa akā e hōʻemi pū kekahika nui o na lakopono ma ka paena.

Ua hoʻololi ʻia ka Welding Laser vs TIG Welding i 2024

E leka uila iā mākou no nā mea hou aku e pili ana i ka ʻōnaehana welding laser lima

No ke aha e hoʻohana ai i ke kinoea pale i ka welding?

He kuleana koʻikoʻi ke koho o ke kinoea pale

Ke kinoea pale no ka welding TIG: Argon

I ka pili ana i ka wiliwili,

Pono ke koho o ke kinoea pale no ka hōʻoia ʻana i nā hopena kiʻekiʻe.

ʻO ka mea kūikawā, ʻo TIG welding a me ka welding laser paʻa i nā koi like ʻole a me nā koho

I ka wā e pili ana i ka pale kinoea, e pili ana i ka hana a me ke kumukūʻai.

Ke kinoea pale i lokoTIG Welding

I ka TIG (Tungsten Inert Gas) welding,

ʻO ke kinoea pale mua i hoʻohana ʻiamaʻemaʻe kiʻekiʻeargon.

Ua koho ʻia kēia kinoea maikaʻi no kona mākaukau maikaʻi loapale i ka wai weld

Mai ka hoʻohaumia ʻana o ka lewa, ʻoi aku ka oxidation.

Hiki ke alakaʻi i ka oxidationnā hemahemai ka weld, e like me ka porosity a me nā hui palupalu,

ʻO ka meahoʻopaʻapaʻaka paʻa piha o ka metala.

Ma muli o kona pono,

Pono pinepine ʻo TIG welding amauka hoʻolako ʻana i ka argon i loko o ke kaʻina hana kuʻi.

Eia nō naʻe, hiki i ka argon ke kūʻai aku i nā kumukūʻai kiʻekiʻe,

ʻOi loa i nā papahana e koi ana i ka wiliwili nui.

Ke kinoea pale i lokoKuʻi lima lima lima

ʻO ke kinoea pale ʻokoʻa no ka welding laser: nitrogen

Ma ka ʻaoʻao ʻē aʻe, hoʻohana pinepine ka welding laser paʻa lima i ka nitrogen e like me ke kinoea pale.

ʻAʻole wale ka Nitrogenponoi ka pale ʻana i ka oxidation

Akā ʻoi aku ka nuikumu kūʻaima mua o ka argon.

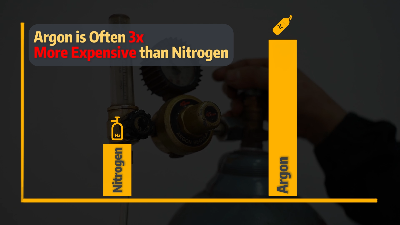

Hiki ke nui ke kumu kūʻai;

ʻaneʻane hiki ke Nitrogenekolu manawaʻoi aku ka maikaʻi ma mua o ka argon maʻemaʻe kiʻekiʻe.

Hana kēia i ka nitrogen i koho maikaʻi no nā ʻoihana e ʻimi nei e hōʻemi i nā kumukūʻaime ka mohai olemaikaʻi.

TIG vs Laser Weld: Palekana Koho Gas

Loaʻa i ka mālama kālā ʻoiai e mālama ana i ka maikaʻi

Hoʻohālikelike Kumukūʻai ma waena o Argon a me Nitrogen

Ke hoʻololi nei i ka nitrogen i nā hāʻawi kuʻi lima lima limalehulehupono

Hoʻokohu kālā:

Me kamea nuiʻokoʻa ma waena o ka argon a me ka nitrogen,

ʻO ka hoʻohana ʻana i ka nitrogen hiki ke alakaʻi i ka mālama nui i ka manawa.

ʻo kēiapono loano nā papahana nui a ʻoihana paha

Hana i nā hana kuʻi pinepine.

Palekana pono:

Hāʻawi ka Nitrogenpale ponokū'ē i ka oxidation,

E hōʻoia i ka paʻa ʻana o ka weldmaemae a ikaika.

ʻOiai ʻike ʻia ʻo argon no kāna pale ʻoi aku ka maikaʻi,

ʻO ka nitrogen mauhe koho kūponoe hoʻokō pono i nā pono o nā noi wili he nui.

Hoʻohālikelike i ke kaʻina hana welding: Laser vs TIG Welding

Loaʻa i ka ʻenehana i nā hopena maikaʻi loa

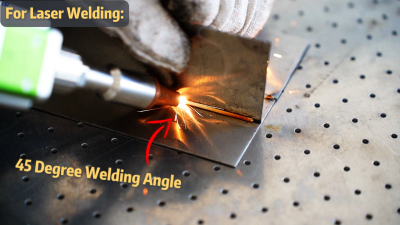

ʻO ke kihi kūpono no ka welding laser: 45 degere

Ke holo pono ke kinoea pale,

ʻO ka manawa kēia e nānā ai i ke kaʻina hana kuʻihao maoli.

ʻO ka wiliwili TIG (Tungsten Inert Gas) a me ka wiliwili lima lima

Koiʻenehana pololeie hoʻokō i nā hopena kiʻekiʻe,

Eia naʻe, ʻokoʻa lākou i kā lākou mau koi kikoʻī a me nā ʻano hana.

TIG Weldingʻenehana

Manaʻo e mālama i ka electrode ma kahika mamao kūpono a me ka wikiwikie hana a alakai i ka wai weld.

Hiki ke ʻokoʻa kēia mamao ma muli o ka mea a me ka mānoanoa e welded ʻia.

Ka mālama ʻana i ke kihi kūpono, maʻamau a puni15 a 20 degere,

Kōkua i ka loaʻa ʻana o kahi weld kūpaʻa a maʻemaʻe.

Kuʻi lima lima limaʻenehana

ʻO kekahi o nā pono o ka welding laser ʻo ka hiki ke hoʻonohonoho i kahi kihi kūlike

ʻO ka maʻamau a puni45 degere, e ʻae ana i ka hoʻokele maʻalahi o ke kaʻina hana wili.

Ke hoʻonohonoho ʻia ke kihi, mālamahe mama mauhe kī.

Hoʻohana pinepine ʻia ka welding laser paʻa limaemi ka welahoʻohālikelike ʻia me ka wiliwili TIG.

'O ia ho'i, aialiʻiliʻi ka pilikia o ka warping a distortion,

Hana ia i mea kūpono no ka hana pololei ma nā mea ʻoi aku ka lahilahi.

Laser Weld Strength vs TIG: Debunking Myths

Manaʻo kuhihewa maʻamau e pili ana i ka welding laser

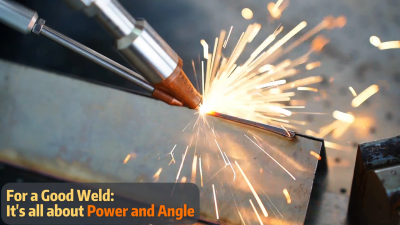

No ka Welding Laser Lima maikaʻi: Mana & Angle

ʻO kekahi o nā pōmaikaʻi nui o ka welding laser paʻa lima ʻo ia ka hiki ke hāʻawi i ka ikehu concentratedpololeikahi e pono ai.

Me kanā hoʻonohonoho mana kūponoa hekihi kūpono

ʻO ka maʻamau a puni45 degere, hiki i ka welding laser ke hoʻokō i ke komo maikaʻi a me ka ikaika.

Ka Puke Mana Pono

He mea koʻikoʻi ka hoʻonohonoho mana o ka welder laser.

Hiki ke hopena i ka haʻahaʻa haʻahaʻa o ka manalawa ole ke komo ana, e alakai ana i na welds nawaliwali.

ʻO ka mea ʻē aʻe, ʻo kahi pae mana kūpono e hiki ai i ka laser ke hoʻoheheʻe maikaʻi i ka mea, e hana ana i nā hui ikaika.

ʻAʻole loaʻa nā hopena i makemake ʻia ka hoʻohana ʻana i nā mea hana underpowered.

ʻO ka TIG a me ka hoʻoheheʻe ʻana i ka lima lima he kūpono

Makemake ʻoe e aʻo hou e pili ana i ka welding laser paʻa lima?

Handheld Laser Weld: Pehea e mālama ai i nā lako

ʻO ka mālama pono a me ka nānā ʻana i nā kikoʻī e hōʻoia i ka huahana a me ka hilinaʻi

Ua ʻike paha ʻoe ua hoʻokaʻawale ʻia ʻo TIG (Tungsten Inert Gas) a me ka welding laser lima.

ʻAʻole hiki ke hoʻohana ʻia nā ʻano kuʻi?

ʻO ia hoʻi, ma lalo o nā kūlana kūpono a me ka mālama pono,

ʻO nā mea nui i hoʻohanaʻia i kēia mau kaʻina hana hiki ke lōʻihi

Me ka pono ʻole e hoʻololi pinepine.

Nā Mea Hoʻohana ʻole

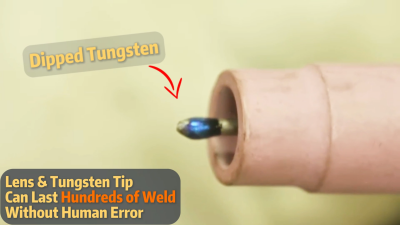

Kuʻi ʻia ka hewa Tungsten no ka wiliwili ʻana o TIG

ʻO ka electrode tungsten kahi mea koʻikoʻi i ka welding TIG.

ʻAʻole like me nā electrodes consumable i hoʻohana ʻia i nā ʻano hoʻoheheʻe ʻē aʻe,

e like me ka MIG welding, ka tungsten electrodeaole heheei ke kaʻina hana kuʻi.

Akā, mālama ia i kona kūpaʻa, hiki ke hoʻohana lōʻihi.

Eia nō naʻe, hiki i ka electrode ke lilo i haumia a i ʻole "hoʻopaʻa ʻia" inā loaʻakokoke loa i ka wai wiliwili hehee.

Ma ia mau hihia, pono e ʻoki ʻia i hope e hoʻihoʻi i kona ʻoi a me ka hana pono.

Mālama mauʻO ka electrode tungsten he mea nui ia no ka hoʻokō ʻana i nā welds maʻemaʻe, kiʻekiʻe.

Hoʻomākaukau ʻia ʻo Laser Weld

Nā Lens Laser no ka mālama ʻana i ka welding laser lima

Ma ka hoʻoheheʻe ʻana i ka laser paʻa lima, ʻo ka lens laser ka mea kikoʻī no ka kukuna laser.

Hiki ke lōʻihi ka lens i hoʻonohonoho pono ʻia, e hāʻawi ana i ka hana mau.

Eia naʻe, inā nahā ka lens ma muli o ke kūlana kūpono ʻole a i ʻole ka ʻike ʻana i ka wela nui

Pono e pani ʻia.

He mea koʻikoʻi ka mālama ʻana i ka lens i ke kūlana maikaʻi,

ʻOiai hiki i ka pōʻino liʻiliʻi ke hoʻopilikia i ka pololei a me ka pono o ka laser, e alakaʻi ana i nā welds suboptimal.

Makemake ʻoe i kahi alakaʻi kuhikuhi piha no ka welding laser paʻa lima?

Hāʻawi ka welding laser lima i nā pono he nui,

Akā, pono ia i ka nānā pono i nā protocols palekana.

E ʻimi kēia ʻatikala i nā manaʻo palekana koʻikoʻi no ka welding laser paʻa lima.

E hāʻawi pū i nā ʻōlelo aʻoaʻo no ka pale ʻana i ke koho kinoea a me nā koho uea hoʻopihapiha no nā ʻano metala maʻamau.

Ua like ka ikaika o ka welding laser e like me ka welding TIG?

Hoʻopili lasera me TIG (Tungsten Inert Gas) welding ua kaulana no ko lakou pololei a me ka maikai i ka hui metala.

Akā, pehea lākou e hoʻopaʻa ai i kekahi i kekahi ma ke ʻano o ka ikaika?

Ma kēia wikiō, e luʻu mākou i nā ʻokoʻa nui mahana weld,mea pili, alōʻihi holoʻokoʻama waena o ka welding laser a me TIG.

Kuʻi lima lima lima lima (Handheld Laser Weld)

ʻO kahi hoʻohui waiwai i ka Landscape Laser Weld Landscape

ʻO ka mea wili laser liʻiliʻi e hana i ke kumu kūʻai a hiki ke kūʻai aku

Me kahi mīkini paʻakikī a liʻiliʻi.

Hoʻolako ʻia ka mīkini welder laser portable me kahi puʻu welder lima lima hiki ke hoʻoneʻe ʻiamāmā.

A maʻalahi no ka nui-laser welding noi makekahi kihiaʻilikai.

Nā ʻano ʻano like ʻole o nā nozzles welder laser.

ʻO kahi ʻōnaehana hānai uea koho koho e maʻalahi ka hana hoʻoheheʻe laser a maikaʻi ia no ka poʻe hoʻomaka.

5 mau mea e pili ana i ka welding laser (i hala ʻoe)

Inā hauʻoli ʻoe i kēia wikiō, no ke aha e noʻonoʻo ʻole aike kau inoa nei i kā mākou Youtube Channel?

Nā noi pili e makemake paha ʻoe:

He koho maikaʻi loa ʻo Handheld Laser Weld no nā hana wili lima

A hoʻomaka ka wā e hiki mai ana me ʻoe!

Ka manawa hoʻouna: Sep-14-2024