Laser Cleaning Grease

Laser cleaning can effectively remove grease, especially in industrial applications.

Portable handheld laser cleaning machines use high-intensity laser beams to vaporize or displace contaminants

like grease, rust, and paint from surfaces.

Does Laser Cleaning Remove Grease?

How it Works and Benefits of Laser Cleaning Grease

The laser emits energy that is absorbed by the grease

causing it to heat rapidly and either vaporize or break down

The focused beam allows for precise cleaning without damaging the underlying material

making it suitable for various surfaces.

Unlike traditional cleaning methods that may require chemicals

laser cleaning typically uses only light and air, reducing chemical waste.

Benefits of Laser Cleaning for Grease Removal

1. Efficiency: Quick removal of contaminants with minimal downtime.

2. Versatility: Effective on different materials, including metals, plastics, and composites.

3. Reduced Waste: Minimal secondary waste compared to chemical cleaners.

What Can a Laser Cleaning Machine Clean?

Here’s an in-depth look at what specific materials these machines can effectively clean:

Laser Cleaning: Metals

1. Rust and Oxidation:

Lasers can efficiently remove rust from steel surfaces

without damaging the underlying metal.

2. Weld Spatter:

On metallic surfaces, lasers can eliminate weld spatter,

restoring the appearance and integrity of the metal

without abrasive chemicals.

3. Coatings:

Lasers can strip paint, powder coatings, and other surface treatments from metals.

Laser Cleaning: Concrete

1. Stains and Graffiti:

Laser cleaning is effective for

removing graffiti and stains

from concrete surfaces.

2. Surface Preparation:

It can be used to prepare concrete surfaces for bonding

by removing contaminants

and roughening the surface

without mechanical tools.

Laser Cleaning: Stone

1. Natural Stone Restoration:

Lasers can clean and restore natural stone surfaces,

such as marble and granite,

by removing dirt, oil, and other residues

without scratching the surface.

2. Moss and Algae:

On outdoor stone surfaces,

lasers can efficiently remove biological growth

like moss and algae

without the use of harsh chemicals.

Laser Cleaning: Plastic

1. Surface Cleaning:

Certain plastics can be cleaned of contaminants, inks, and residues using lasers.

This is particularly useful in the automotive and packaging industries.

2. Marking Removal:

Lasers can also remove unwanted markings on plastic surfaces,

such as labels or scratches,

without affecting the structural integrity of the material.

Laser Cleaning: Wood

1. Surface Treatment:

Lasers can clean

and prepare wooden surfaces

by removing dirt and old finishes.

This process can enhance the wood’s appearance

while preserving its texture.

2. Burn Marks: In cases of fire damage,

aser cleaning can effectively remove burn marks

and restore the wood underneath.

Laser Cleaning: Ceramic

1. Stain Removal:

Ceramics can be cleaned of tough stains

and residues using lasers,

which can penetrate the surface layer

without cracking or damaging the ceramic.

2. Restoration:

Lasers can restore the shine

of ceramic tiles and fixtures

by removing dirt and buildup

that traditional cleaning methods might miss.

Laser Cleaning: Glass

Cleaning: Lasers can remove contaminants from glass surfaces, including oils and adhesives without damaging the material.

Want to Know about How Laser Cleaning Grease Works?

We Can Help!

Laser Cleaning Applications: Laser Cleaning Grease

In the automotive sector

technicians use handheld lasers to eliminate grease buildup on engine components and chassis

improving maintenance processes and reducing downtime.

Manufacturing also benefits,

as operators can quickly clean tools and machinery,

ensuring optimal performance and prolonging equipment life without the need for harsh solvents.

In food processing,

lasers are utilized to maintain hygiene by removing grease

from surfaces and machinery, ensuring compliance with health regulations.

Similarly, aerospace applications see lasers employed

to clean grease from intricate parts, enhancing safety and reliability.

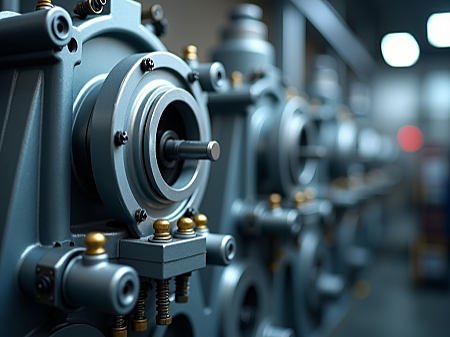

Grease in Manufacturing

Manufacturers often face the issue of grease accumulation on intricate machinery parts.

Handheld laser cleaning allows operators to target specific areas

without affecting surrounding components.

This precision is crucial for maintaining the integrity of delicate mechanisms

and ensuring optimal performance.

Laser Cleaning Grease in: Manufacturing

Handheld lasers can quickly remove grease,

significantly reducing the time machinery is out of operation.

This efficiency is vital in high-production environments

where minimizing downtime directly impacts profitability.

Using handheld lasers minimizes waste generated from cleaning processes.

Unlike traditional methods,

which can result in sludge and chemical runoff, laser cleaning produces minimal residue.

This not only simplifies waste disposal

but also lowers the overall cleaning costs.

Grease in Automotive

Handheld laser cleaning systems are

particularly effective for removing grease and oil from engine parts,

such as cylinder heads and crankshafts.

Laser Cleaning Grease in: Automotive

The precision of lasers allows technicians

to clean intricate surfaces without risking damage to sensitive components.

Handheld lasers can also eliminate grease buildup on brake calipers and rotors,

ensuring optimal braking performance.

This precision cleaning helps prevent brake fade and maintains the reliability of the braking system,

which is vital for driver safety.

Grease in Food Processing

Food processing facilities must adhere to strict health and safety regulations.

Handheld laser cleaning helps meet these standards by ensuring that all surfaces are free from grease and contaminants.

By using lasers, manufacturers can demonstrate their commitment to hygiene and compliance, reducing the risk of foodborne illnesses.

Laser Cleaning Grease in: Food Processing

The reliance on chemical cleaners can pose risks in food processing environments,

including contamination and allergen concerns.

Handheld laser cleaning eliminates the need for these chemicals,

providing a safer alternative that minimizes the risk of chemical residues on food contact surfaces.

Grease in Construction

Construction equipment, such as excavators, bulldozers, and cranes,

often accumulates grease and oil from regular use.

Handheld laser cleaning allows operators to efficiently remove this buildup,

ensuring that machinery operates smoothly and reducing the risk of mechanical failures.

The precision of lasers enables targeted cleaning,

preserving the integrity of sensitive components.

Laser Cleaning Grease in: Construction

Handheld lasers are ideal for cleaning various tools and accessories used on construction sites,

including power tools and scaffolding.

By effectively removing grease and grime,

lasers help maintain tool performance and extend their lifespan,

ultimately saving costs associated with repairs and replacements.

Grease in Energy Industries

In offshore oil and gas operations,

equipment and surfaces are exposed to harsh environments that can lead to significant grease buildup.

Handheld lasers are portable and can be utilized in challenging conditions,

making them ideal for maintaining the cleanliness of platforms

and machinery without requiring extensive disassembly.

Laser Cleaning Grease in: Energy Industries

Handheld lasers are adaptable for various energy sectors,

from traditional oil and gas

to renewable energy installations like wind and solar farms.

They can effectively clean components

such as solar panels and wind turbine parts,

ensuring optimal performance and efficiency.

Do Laser Cleaning Machines Really Work?

Do laser cleaning machines really work? Absolutely!

What is Laser Cleaning & How it Works?

For Laser Cleaning Grease?

Pulsed Laser Cleaner (100W, 200W, 300W, 400W)

For manufacturers looking to maintain high standards of cleanliness and quality while optimizing their production lines, laser cleaning machines offer a powerful solution that enhances both performance and sustainability.

Laser Power: 100-500W

Pulse Length Modulation: 10-350ns

Fiber Cable Length: 3-10m

Wavelength: 1064nm

Laser Source: Pulsed Fiber Laser

3000W Laser Cleaner (Industrial Laser Cleaning)

For mass cleaning and some large structure body cleaning like pipe, ship hull, aerospace craft, and auto parts, the 3000W fiber laser cleaning machine is well qualified with fast laser cleaning speed and high-repetition cleaning effect.

Laser Power: 3000W

Clean Speed: ≤70㎡/hour

Fiber Cable: 20M

Scanning Width: 10-200nm

Scanning Speed: 0-7000mm/s

Laser Source: Continuous Wave Fiber