Laser Cleaning Wood

While laser cleaning is generally safe for wood, it's important to conduct tests on a small, inconspicuous area first to ensure the laser settings are appropriate for the specific type of wood and its condition.

With the right setup and precautions, laser cleaning can be a highly efficient and effective way to clean and restore wood surfaces.

What Is Pulsed Laser Cleaning?

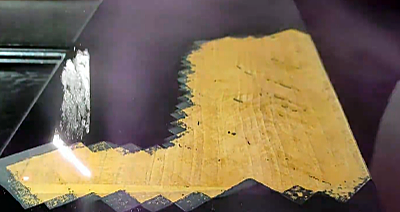

Pulsed Laser Cleaner Stripping Oxide Layer From Wooden Stand

Pulsed Laser Cleaning is a specialized technique

That uses high-intensity,short-duration laser pulses

To remove contaminants, coatings, or unwanted materials

From the surface of a substrate without causing damage.

Pulsed lasers store and release energy periodically,

Creating a series of intense laser pulses.

These pulses have a very high energy density

That can effectively remove materials through processes

Like sublimation, vaporization, and concussive detachment.

Compared to Continuous Wave (CW) Lasers:

Versatility:

Pulsed lasers can be used to clean a wide range of materials, including metals, ceramics, and composites.

By adjusting parameters like pulse energy, duration, and repetition rate.

Better Heat Control:

Pulsed lasers can better control the heat input to the substrate, preventing excessive heating or micro-melting that could damage the underlying material.

This makes pulsed lasers well-suited for cleaning delicate or heat-sensitive surfaces.

Pulsed laser cleaning is commonly used in applications such as rust, paint, oil, and oxide layer removal from metal surfaces.

It is particularly effective for precision cleaning tasks where tight control over the cleaning process is required, such as mold cleaning.

Do Laser Cleaners Work on Wood?

Laser Cleaning Paint from Wooden Door

Yes, laser cleaners can be highly effective for cleaning and restoring wood surfaces.

Laser cleaning is a non-contact, precise method,for removing unwanted coatings, stains, and contaminants from wood

Without damaging the underlying material.

The laser beam is directed at the wood surface,where the contaminants absorb the laser energy.

This causes the contaminants to vaporize and detach from the wood,

Leaving the wood surface clean and undamaged.

For Stripping Paint, Varnish and Stains from Wood:

Laser cleaning is particularly useful for removing paint, varnish, and stains from wood,

including on delicate or intricate woodwork like antique furniture or wooden sculptures.

The laser can be precisely adjusted to target only the unwanted layers without harming the wood itself.

This makes laser cleaning a superior alternative to traditional methods

like sanding or chemical stripping,which can be more labor-intensive and risk damaging the wood.

For Removing Dirt, Grease and Other Contaminants:

In addition to paint and stain removal,

Laser cleaning can also effectively remove dirt, grease, and other surface contaminants from wood,

Restoring its natural color and grain.

The process is also useful for cleaning and purifying wooden structures and artifacts,

Helping to preserve cultural heritage.

Laser Cleaning is Highly Efficient to Clean & Restore Wood Surface

With the Right Setup and Precautions

Does Laser Wood Stripping Work?

Laser Cleaning Stripping Paint from Wooden Frame

Yes, laser wood stripping is an effective and efficient method for removing paint, varnish, and other coatings from wood surfaces.

Compared to traditional methods like sanding or chemical stripping,laser wood cleaning is significantly faster and more efficient.

It can remove coatings from large areas

In a fraction of the time required by manual techniques.

Versatility Through Adjustable Power & Focus:

The laser's adjustable power and focus settings

Make it versatile enough to handle different wood types and coating thicknesses.

This allows for customized cleaning to suit the specific project needs.

Environmentally Friendly with Less Mess:

Laser wood stripping is also a more environmentally friendly option,

As it does not require the use of harsh chemicals.

This eliminates the need for hazardous waste disposal

And reduces the impact on the surrounding environment.

Why Should You Choose Laser to Clean Wood?

Laser Cleaning Heavy Coating From Wood

Laser cleaning is an excellent choice for cleaning wood surfaces due to its numerous advantages over traditional cleaning methods.

Here's Why you Should Choose Laser to Clean Wood

Precision and Control:

Laser cleaning allows for precise and controlled removal of unwanted coatings, such as paint, varnish, or stains, without damaging the underlying wood.

The laser can be precisely targeted to only affect the surface layer, leaving the wood itself unharmed.

Non-Abrasive Cleaning:

Unlike sanding or chemical stripping, laser cleaning is a non-contact method that does not physically abrade the wood surface.

This helps maintain the integrity and appearance of the wood, especially on delicate or antique pieces.

Versatility:

Laser cleaning systems can be adjusted to accommodate different types of wood and varying levels of contamination.

This versatility allows the technique to be used on a wide range of wood restoration and maintenance projects.

Cost-Effectiveness:

With the price tag dropping with laser cleaners on the market, the speed, precision, and reduced labor.

And material costs associated with laser cleaning definitely make it a more cost-effective solution in the long run.

What Types of Wood Can be Laser Cleaned?

Laser Cleaning Wooden Table for Restoration

Laser Cleaned Wooden Table

Many different types of wood can be effectively cleaned using laser technology.

The most suitable woods for laser cleaning are those that are not too dark or reflective in color.

Suitable for Laser Cleaning: Hardwood

Hardwoods like maple, oak, and cherry are excellent candidates for laser cleaning,

As their surfaces are able to absorb the laser energy

And have their dirt, grime, and stains vaporized.

Darker, denser woods like ebony and rosewood can also be laser cleaned

But may require more passes of the laser to fully remove contaminants.

Less Ideal for Laser Cleaning: Lighter Coloured & Reflective Wood

In contrast, lighter colored and more reflective woods

Like pine or laminate flooring are less ideal (But Still Cleans Effectively)

The key is finding woods that have a surface that can efficiently absorb the laser's energy

In order to vaporize the dirt and stains,

without the laser damaging or burning the underlying wood.

Laser Cleaning Machine for Wood

Due to the noncontinuous laser output and high peak laser power, the pulsed laser cleaner is more energy-saving and suitable for fine parts cleaning.

The adjustable pulsed laser is flexible and serviceable in rust removal, paint removal, stripping coating, and eliminating oxide and other contaminants.

Versatility Through Adjustable Power Parameter

Low Operating and Maintenance Costs

Non-Contact Cleaning Minimize Wood Damage

What is Laser Cleaning?

Why Laser Ablation is the Best

What Applications Needs Laser Wood Cleaning?

Laser Cleaning Grime From a Wooden Brush Handle

Restoration of Antique and Vintage Furniture:

Laser cleaning is an excellent method for restoring the beauty of antique and vintage wooden furniture.

It can gently remove dirt, grime, and old finishes without damaging the underlying wood surface, preserving the integrity of these valuable pieces.

Removal of Contaminants from Wood Surfaces:

Laser cleaning is effective in removing various contaminants from wood surfaces, such as oil, grease, and adhesive residues.

This makes it useful for cleaning industrial equipment, medical devices, and other applications where a clean, contaminant-free wood surface is required.

Preparation for Refinishing and Finishing:

Before applying new finishes or coatings to wooden surfaces, laser cleaning can be used to prepare the surface by removing old finishes, stains, and other impurities.

This ensures better adhesion and a more uniform appearance of the new finish.

Cleaning of Wooden Floors and Cabinetry:

Laser cleaning can be an efficient and environmentally friendly method

For cleaning and maintaining wooden floors, cabinets, and other wooden architectural elements in residential and commercial settings.

Removal of Graffiti and Unwanted Markings:

Laser cleaning can be used to remove graffiti, paint, and other unwanted markings

From wooden surfaces without causing damage to the underlying wood.

Preparation for Laser Engraving and Marking:

Laser cleaning can be used to prepare wooden surfaces for laser engraving or marking

By removing any contaminants or coatings that could interfere with the laser's performance.

Cleaning of Wooden Sculptures and Artwork:

Laser cleaning is a gentle and precise method for cleaning and restoring wooden sculptures, carvings,

And other wooden artworks without risking damage to the delicate surfaces.