Weed Barrier Fabric: A Comprehensive Guide

Introduction of Weed Barrier Fabric

What is Weed Barrier Fabric?

Weed barrier fabric, also known as fabric weed barrier, is an essential landscaping material designed to block weeds while allowing water and nutrients to pass through.

Whether you need a temporary solution or long-term weed control, choosing the best weed barrier fabric ensures effective results.

High-quality options, including laser-cut weed barrier fabric, provide precision durability for gardens, pathways, and commercial landscapes.

Weed Barrier Fabric

Types of Weed Barrier Fabric

Woven Fabric

Made from woven polypropylene or polyester.

Durable, long-lasting (5+ years), and great for high-traffic areas.

Best for: Gravel paths, walkways, and under decks.

Biodegradable Fabric (Eco-Friendly Option)

Made from natural materials like jute, hemp, or paper.

Breaks down over time (1–3 years).

Best for: Organic gardening or temporary weed control.

Perforated Fabric (Pre-Punched for Plants)

Has pre-cut holes for easy planting.

Best for: Landscaping projects with specific plant spacing.

Non-Woven Fabric

Made from bonded synthetic fibers (polypropylene or polyester).

Less durable than woven but still effective for moderate use.

Best for: Flower beds, shrub borders, and vegetable gardens.

Features & Benefits of Laser-Cut Weed Barrier

✔ Precision Planting – Laser-cut holes or slits ensure consistent plant spacing.

✔ Time-Saving – Eliminates the need to manually cut holes for each plant.

✔ Durable Material – Typically made from woven or heavy-duty non-woven polypropylene for long-lasting weed suppression.

✔ Optimal Water & Air Flow – Maintains permeability while blocking weeds.

✔ Customizable Patterns – Available in various hole sizes (e.g., 4", 6", 12" spacing) for different plants.

How to Install Weed Barrier Fabric

Clear the Area – Remove existing weeds, rocks, and debris.

Level the Soil – Smooth out the ground for even fabric placement.

Lay the Fabric – Unroll and overlap edges by 6–12 inches.

Secure with Staples – Use landscape pins to hold fabric in place.

Cut Planting Holes (if needed) – Use a utility knife for precise cuts.

Add Mulch or Gravel – Cover with 2–3 inches of mulch for aesthetics and added weed suppression.

Pros of Weed Barrier Fabric

Cons of Weed Barrier Fabric

✔ Weed Suppression – Blocks sunlight, preventing weed growth.

✔ Moisture Retention – Helps soil retain water by reducing evaporation.

✔ Soil Protection – Prevents soil erosion and compaction.

✔ Low Maintenance – Reduces the need for frequent weeding.

✖ Not 100% Weed-Proof – Some weeds may grow through or on top over time.

✖ Can Restrict Plant Growth – May hinder deep-rooted plants if not installed properly.

✖ Degrades Over Time – Synthetic fabrics break down after several years.

Pros & Cons of Laser-Cut Weed Barrier

| Pros ✅ | Cons ❌ |

| Saves time on hole-cutting | More expensive than standard fabric |

| Perfect for uniform plant spacing | Limited flexibility (must match planting layout) |

| Reduces labor in large-scale projects | Not ideal for irregularly spaced plants |

| Long-lasting & durable | May require custom orders for unique patterns |

Key Distinctions

vs. Velvet: Chenille is more textured and casual; velvet is formal with a glossy finish.

vs. Fleece: Chenille is heavier and more decorative; fleece prioritizes lightweight warmth.

vs. Cotton/Polyester: Chenille emphasizes luxury and tactile appeal, while cotton/polyester focus on practicality.

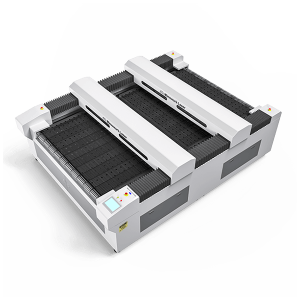

Recommended Weed Barrier Laser Cutting Machine

Laser Power: 100W/150W/300W

Working Area (W * L):1600mm * 1000mm (62.9” * 39.3 ”)

Laser Power: 100W/150W/300W

Working Area (W * L): 1800mm * 1000mm (70.9” * 39.3 ”)

Laser Power: 150W/300W/450W

Working Area (W * L): 1600mm * 3000mm (62.9’’ *118’’)

Application of Weed Barrier Fabric

Under Mulch in Flower Beds & Gardens

How it works: Prevents weeds from growing through mulch while allowing water and air to reach plant roots.

Best fabric type: Non-woven or woven polypropylene.

In Vegetable Gardens

How it works: Reduces weeding labor while allowing crops to grow through pre-cut holes.

Best fabric type: Perforated (laser-cut) or biodegradable fabric.

Under Gravel, Rocks, or Pathways

How it works: Keeps gravel/rock areas weed-free while improving drainage.

Best fabric type: Heavy-duty woven fabric.

Around Trees & Shrubs

How it works: Prevents grass/weeds from competing with tree roots.

Best fabric type: Woven or non-woven fabric.

Under Decks & Patios

How it works: Blocks weeds from growing in hard-to-reach areas.

Best fabric type: Heavy-duty woven fabric.

Related Videos

Cordura Laser Cutting - Making a Cordura Purse with a Fabric Laser Cutter

How to laser cut Cordura fabric to make a Cordura purse (bag)?

Come to the video to figure out the whole process of 1050D Cordura laser cutting.Laser cutting tactical gear is a fast and strong processing method and features top quality.

Via specialized material testing, an industrial fabric laser cutting machine is proven to have an excellent cutting performance for Cordura.

Denim Laser Cutting Guide | How to Cut Fabric with a Laser Cutter

Come to the video to learn the laser cutting guide for denim and jeans.

So fast and flexible whether for customized design or mass production it is with the help of fabric laser cutter.Polyester and denim fabric are good for laser cutting, and what else?

Any Question to Laser Cutting Weed Barrier Fabric?

Let Us Know and Offer Further Advice and Solutions for You!

Laser Cut Weed Barrier Fabric Process

Laser cutting chenille fabric involves using a high-precision laser beam to melt or vaporize fibers, creating clean, sealed edges without fraying. This method is ideal for intricate designs on chenille’s textured surface.

Step-by-Step Process

Material Preparation

Weed barrier fabric is typically made of polypropylene (PP) or polyester (PET) non-woven material, requiring heat resistance.

Thickness: Usually 0.5mm–2mm; laser power should be adjusted accordingly.

Design Preparation

Recommended laser type: CO₂ laser, suitable for synthetic fabrics.

Typical settings (test and adjust):

Power: Adjust based on fabric thickness

Speed: Slower speed = deeper cuts.

Frequency: Ensure smooth edges.

Cutting Process

Secure the fabric with clamps or tape to keep it flat.

Test-cut on scrap material to optimize settings.

The laser cuts along the path, melting edges to minimize fraying.

Monitor quality to ensure complete cuts without excessive burning.

Post-Processing

Clean edges with a brush or compressed air to remove charred residue.

Check integrity to ensure all cuts are fully separated.

FAQS

Primary materials: Usually polypropylene (PP) or polyester (PET) non-woven fabric, some with UV additives for sunlight resistance.

Economy grade: 1-3 years (no UV treatment)

Professional grade: 5-10 years (with UV stabilizers)

Premium fabric: Permeable (≥5L/m²/s drainage rate)

Low-quality products may cause puddling

Comparison:

| Feature | Laser Cutting | Traditional Cutting |

| Precision | ±0.5mm | ±2mm |

| Edge Treatment | Auto-sealed edges | Prone to fraying |

| Customization Cost | Cost-effective for small batches | Cheaper for mass production |

PP: Recyclable but slow to decompose

Bio-based alternatives emerging (e.g., PLA blends)