Laser Cutting Automotive Bumper

What is a Bumper of a Car?

An Automotive Bumper (Car Front Bumper) is a vital component located at the front of a vehicle, specifically designed to absorb and minimize the impact of collisions or accidents. It serves as a protective barrier, shielding the front of the car from damage and reducing the impact forces transferred to the vehicle's occupants. In addition to its safety function, the front bumper also plays an aesthetic role, contributing to the overall design and appearance of the car. Modern bumpers are typically made of a combination of plastic, fiberglass, or other lightweight materials to provide durability while minimizing weight.

Laser Cutting Plastic for Bumpers on Car

When it comes to cutting plastic for car bumpers, laser cutting offers several advantages that set it apart from other cutting methods:

Unmatched Precision:

In contrast, laser cutting machines simplify the entire manufacturing process. With laser cutting technology, you can precisely cut mesh fabric, contour-cut non-woven fabric adhered to heat conductive wires, and laser perforate and cut seat covers. MimoWork is at the forefront of developing laser cutting technology, improving car seat production efficiency while reducing material waste and saving valuable time for manufacturers. Ultimately, this benefits customers by ensuring high-quality temperature-controlled seats.

High Versatility:

Laser cutting is highly versatile, capable of cutting plastic materials of various thicknesses and complexities. It can handle both thin and thick plastic sheets, allowing for flexibility in design and accommodating different bumper specifications. Laser cutting can also create intricate shapes, curves, and perforations with ease, offering limitless design possibilities for car bumpers.

Minimal Material Waste:

Laser cutting is a non-contact process, meaning that it does not involve physical contact with the plastic material. As a result, there is minimal material waste compared to other cutting methods that may involve additional trimming or machining processes. Laser cutting maximizes material utilization, leading to cost savings and reduced environmental impact.

Clean and Smooth Edges:

The laser beam produces clean, smooth, and burr-free edges when cutting plastic. This eliminates the need for post-processing or additional finishing steps, saving time and effort. The resulting smooth edges also contribute to the overall aesthetics of the car bumper, providing a polished and professional appearance.

Non-Destructive Process:

Laser cutting minimizes physical stress on the plastic material, as it is a non-contact process. This reduces the risk of warping, distortion, or damage to the bumper during the cutting process. The non-destructive nature of laser cutting ensures the integrity and quality of the car bumper components.

Video Showcase | Laser Cutting Car Parts

Find more videos about our laser cutters at our Video Gallery

Equipped with a dynamic auto-focus sensor (Laser Displacement Sensor), the real-time auto-focus co2 laser cutter can realize laser cutting car parts. With the plastic laser cutter, you can complete high-quality laser cutting of automotive parts, car panels, instruments, and more due to the flexibility and high accuracy of dynamic auto-focusing laser cutting.

Laser cutting offers unmatched precision, versatility, customization options, and efficiency when cutting plastic for car bumpers. Its ability to produce clean cuts, accommodate complex designs, and optimize material utilization makes it a preferred choice for manufacturing high-quality and visually appealing car bumpers.

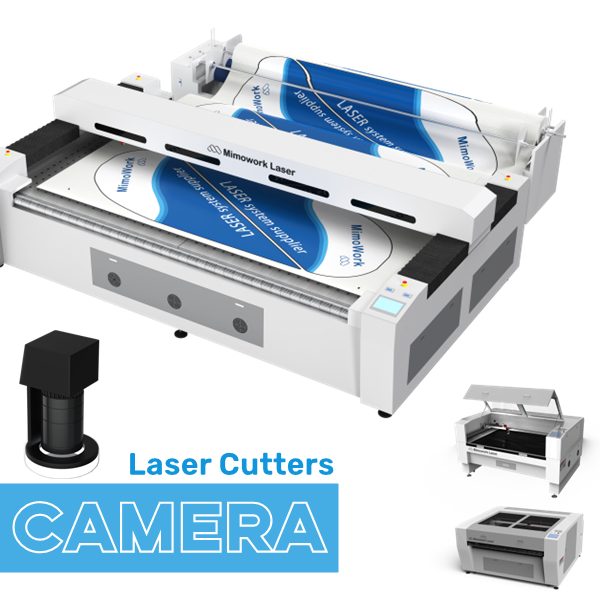

Recommended Laser Cutter for Vehicle Bumper

Comparison Between Laser cutting & Traditional Cutting Methods

In Conclusion

Laser cutting for automotive bumpers offers a range of benefits that traditional cutting methods simply can't match. Laser cutting provides exceptional precision, allowing for clean and accurate cuts, ensuring perfect fitment of bumper components. It offers versatility in handling various thicknesses and shapes of materials, accommodating complex designs and customization. Laser cutting minimizes material waste, maximizing material utilization and reducing environmental impact. It produces smooth edges, eliminating the need for additional finishing processes. The speed and efficiency of laser cutting contribute to faster production times. Moreover, the non-destructive nature of laser cutting minimizes physical stress on the material, ensuring the integrity and quality of the automotive bumpers. Overall, laser cutting is a superior choice for automotive bumpers, delivering precision, versatility, customization, and efficiency.