Laser Cutting Shirt, Laser Cutting Blouse

The Trend of Apparel Laser Cutting: Blouse, Plaid Shirt, Suit

The technology of laser cutting fabric and textiles is pretty mature in the clothing and fashion industry. Many manufacturers and designers have upgraded their clothing and accessories production using the clothing laser cutting machine, to make laser cut blouses, laser cut shirts, laser cut dresses, and laser cut suits. They are popular in the fashion and clothing market.

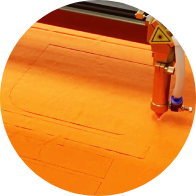

Different from traditional cutting methods like manual cutting and knife cutting, laser cutting clothing is a high-automation workflow including importing design files, auto-feeding the roll fabric, and laser cutting the fabric into pieces. The whole production is automatic, requires less labor and time, but brings higher production efficiency and excellent cutting quality.

Laser cutting machine for garment is advantageous in making various styles of clothing. Any shapes, any size, any patterns like hollow patterns, the fabric laser cutter can make it.

Laser Creates High Value-Added for Your Clothing

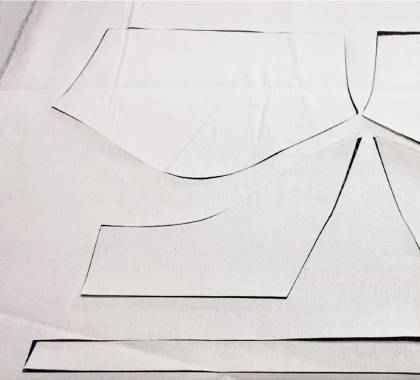

Laser Cutting Apparel

Laser Cutting is a common technology, making use of a powerful and fine laser beam to cut through the fabric. As the moving of the laser head which is controlled by the digital control system, the laser spot turns into a consistent and smooth line, making the fabric different shapes and patterns. Due to the wide compatibility of CO2 laser, the clothing laser cutting machine can handle different materials including cotton, brushed fabric, nylon, polyester, Cordura, denim, silk, etc. That is one of the reasons why using laser cutting machines in the garment industry.

Laser Engraving Apparel

The unique feature of a clothing laser cutting machine, is it can engrave on cloth and textiles, such as laser engraving on the shirt. The laser power and speed are adjustable to control the strength of the laser beam, when you use lower power and higher speed, the laser will not cut through the cloth, on the contrary, it will leave etching and engraving marks on the surface of materials. Same as laser cutting clothing, laser engraving on the clothing is performed according to the imported design file. So you can complete various engraving patterns like logo, text, graphics.

Laser Perforating in Clothing

Laser perforating in cloth is similar to laser cutting. With the fine and thin laser spot, the laser cutting machine can create small holes in the fabric. The application is common and popular in swear shirts and sportswear. Laser cutting holes in the fabric, on the one hand, adds breathability, on the other hand, enriches the appearance of the clothing. By editing your design file and import into the laser cutting software, you will get various shapes, different sizes, and spaces of holes.

Video Display: Laser Cutting Tailor-Made Plaid Shirt

Benefits from Laser Cutting Clothing(shirt, blouse)

Clean & Smooth Edge

Cut Any Shapes

High Cutting Precision

✔ Clean and smooth cutting edge thanks to the crisp laser cutting and instant heat-sealed ability.

✔ Flexible laser cutting brings high convenience for tailor-made design and fashion.

✔ High cutting precision not only guarantees the accuracy of cut patterns, but also minimizes the materials waste.

✔ Non-contact cutting gets rid of the waste for materials and laser cutting head. No fabric distortion.

✔ High automation increases cutting efficiency and saves labor and time costs.

✔ Almost all fabric can be laser cut, engraved, and perforated, to create unique designs for your clothing.

Tailoring Laser Cutting Machine for Garment

• Working Area (W * L): 1600mm * 1000mm

• Laser Power: 100W/150W/300W

• Max Speed: 400mm/s

• Working Area (W * L): 1600mm * 1000mm

• Collecting Area (W * L): 1600mm * 500mm

• Laser Power: 100W / 150W / 300W

• Max Speed: 400mm/s

• Working Area (W * L): 1600mm * 3000mm

• Laser Power: 150W/300W/450W

• Max Speed: 600mm/s

Versatile Applications of Laser Cutting Clothing

Laser Cutting Shirt

With laser cutting, shirt panels can be cut with precision, ensuring a perfect fit with clean, seamless edges. Whether it’s a casual tee or a formal dress shirt, laser cutting can add unique details like perforations or engravings.

Laser Cutting Blouse

Blouses often require fine, intricate designs. Laser cutting is ideal for adding lace-like patterns, scalloped edges, or even complex embroidery-like cuts that add elegance to the blouse.

Laser Cutting Dress

Dresses can be adorned with detailed cutouts, unique hem designs, or decorative perforations, all made possible with laser cutting. This allows designers to create innovative styles that stand out. Laser cutting can be used to cut multiple layers of fabric simultaneously, making it easier to create multi-layered dresses with consistent design elements.

Laser Cutting Suit

Suits require a high level of precision for a sharp, clean finish. Laser cutting ensures that each piece, from lapels to cuffs, is perfectly cut for a polished, professional appearance. Custom suits benefit greatly from laser cutting, allowing for precise measurements and unique, personalized details like monograms or decorative stitching.

Laser Cutting Sportswear

Breathability: Laser cutting can create micro-perforations in sportswear fabrics, enhancing breathability and comfort during physical activity.

Streamlined Design: Sportswear often requires sleek, aerodynamic designs. Laser cutting can produce these with minimal material waste and maximum efficiency.

Durability: Laser-cut edges in sportswear are less prone to fraying, leading to more durable garments that can withstand rigorous use.

• Laser Cutting Lace

• Laser Cutting Leggings

• Laser Cutting Bulletproof Vest

• Laser Cutting Bathing Suit

• Laser Cutting Apparel Accessories

• Laser Cutting Underwear

What are Your Applications? How to Choose Laser Machine for that?

Common Materials of Laser Cutting

Laser Cutting Cotton | Laser Tutorial

Check out More Videos about Laser Cut Fabric >

Laser Cutting Denim

Laser Cutting Cordura Fabric

Laser Cutting Brushed Fabric

FAQ

1. Is it safe to laser cut fabric?

Yes, it is safe to laser cut fabric, provided that the correct safety precautions are taken. Laser cutting fabric and textiles is a widely used method in the clothing and fashion industries due to its precision and efficiency. There are some considerations you need to know:

Materials: Almost all natural and synthetic fabrics are safe to laser cut, but for some materials, they can produce harmful gas during laser cutting, you need to check this material content and purchase laser-safety materials.

Ventilation: Always use an exhaust fan or fume extractor to remove fumes and smoke generated during the cutting process. This helps prevent inhalation of potentially harmful particles and maintains a clean work environment.

Right Operation for Laser Machine: Install and use the laser cutting machine according to the machine supplier's guide. Usually, we will offer professional and considerate tutorial and guide after you receiving the machine. Talk with our Laser Expert >

2. What laser setting is needed to cut fabric?

For laser cutting fabric, you need to pay attention to these laser parameters: laser speed, laser power, focal length, and air blowing. About the laser setting for cutting fabric, we have an article to tell more details, you can check it out: Laser Cutting Fabric Setting Guide

About how to adjust the laser head to find the right focal length, please check this out: How to Determine CO2 Laser Lens Focal Length

3. Does laser cut fabric fray?

Laser cutting fabric can protect the fabric from fraying and splintering. Thanks to the heat treatment from the laser beam, the laser cutting fabric can be finished meanwhile the edge sealing. This is especially beneficial for synthetic fabrics like polyester, which melt slightly at the edges when exposed to laser heat, creating a clean, fray-resistant finish.

Although that, we suggest you first test your material with different laser settings like power and speed, and to find the most suitable laser setting, then carry out your production.