Laser Cutting & Embossing Fleece

Fleece Material Properties

Fleece originated in the 1970s. It refers to polyester synthetic wool that is often used to produce lightweight casual jacket.

Fleece material has good thermal insulation.

This material replicates the insulating nature of wool without the issues that come with natural fabrics such as being wet when heavy, yield relying on the number of sheep, etc.

Due to its properties, fleece material is not only popular in fashion and apparel areas like sportswear, clothing accessories, or upholstery, but also being more and more used for abrasive, insulation, and other industrial purposes.

Why Laser Is The Best Method To Cut Fleece Fabric

1. Clean Edges

The melting point of fleece material is 250°C. It is a poor conductor of heat with low resistance towards heat. It is a thermoplastic fiber.

As the laser is heat treatment thus, fleece is easy to be sealed when processing.

The Fleece Fabric Laser Cutter can provide clean cutting edges in a single operation. No need to do post-processing like polishing or trimming.

2. No Deformation

Polyester filaments and staple fibers are strong because of their crystalline nature and this nature permits the formation of highly effective Vander Wall's forces.

This tenacity remains unchanged even if it is wet.

Therefore, considering the tool wear and efficiency, traditional cutting like knife cutting is rather laborious and inadequate.

Thanks to laser's contactless cutting characteristics, you don't need to fix the fleece fabric to cut, the laser can cut effortlessly.

3. Odorless

Due to the composition of fleece material, it tends to release odor smell during the fleece laser cutting process, which can be simply solved by MimoWork fume extractor and air filter solutions to meet your need for ecological and environmental protection ideas.

How To Laser Cut Fleece Fabric Straight?

To laser cut fleece fabric straight, use a low to medium power setting and a moderate to high cutting speed to prevent excessive melting.

Secure the fabric flat on the laser bed to avoid shifting and perform a test cut to fine-tune the settings.

A single-pass cut works best to achieve clean, smooth edges without fraying.

With proper adjustments, laser cutting fleece ensures precise and professional results.

Auto Nesting Software for Laser Cutting

Renowned for its laser-cut nesting software, takes center stage, boasting high automation and cost-saving capabilities, where maximum efficiency meets profitability.

It's not just about automatic nesting; this software's unique feature of co-linear cutting takes material conservation to new heights.

The user-friendly interface, reminiscent of AutoCAD, blends this with the precision and non-contact advantages of laser cutting.

Laser Embossing Fleece Is A Future Trend

1. Meet Every Standard of Customization

MimoWork laser can reach the preciseness within 0.3mm thus, for those manufacturers who have complex, modern, and high-quality designs, it is simple to produce even one single patch sample and create uniqueness by adopting fleece engraving technology.

2. High Quality

The laser power can be precisely adjusted to the thickness of your materials.

Therefore, it is easy for you to take advantage of the laser heat treatment to gain both visual and tactile senses of depth on your fleece products.

Etching logo or other engraving designs brings outstanding contrast enhancement to fleece fabric.

3. Fast Processing Speed

The pandemic's impact on manufacturing was unpredictable and difficult. Manufacturers are now turning to laser technology to process accurately cut fleece patches and labels in a matter of seconds.

It is sure to be more and more applied to lettering, embossing, and engraving in the coming future. The laser technology with a greater compatibility is winning the game.

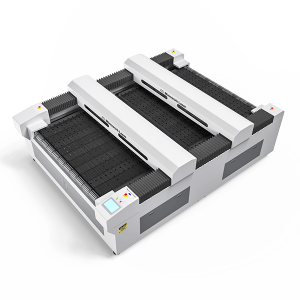

Laser Machine For Cutting & Engraving Fleece

Standard Fabric Laser Cutter Machine

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Laser Power | 100W/150W/300W |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Unrivaled Industrial Fabric Laser Cutting Machine

| Working Area (W * L) | 1600mm * 3000mm (62.9’’ *118’’) |

| Laser Power | 150W/300W/450W |

| Max Speed | 1~600mm/s |

| Acceleration Speed | 1000~6000mm/s2 |