Laser Cutting Foam

Professional and Qualified Foam Laser Cutting Machine

Whether you are looking for a foam laser cutting service or thinking of investing in a foam laser cutter, it's essential to get to know more about CO2 laser technology.

The industrial use of foam is constantly being updated. Today's foam market is composed of many different materials used in a wide range of applications. In order to cut high-density foam, the industry is increasingly finding that laser cutter is very suitable for cutting and engraving foams made of polyester (PES), polyethylene (PE) or polyurethane (PUR).

In some applications, lasers can provide an impressive alternative to traditional processing methods. In addition, custom laser cut foam is also used in artistic applications, such as souvenirs or photo frames.

Benefits from Laser Cutting Foam

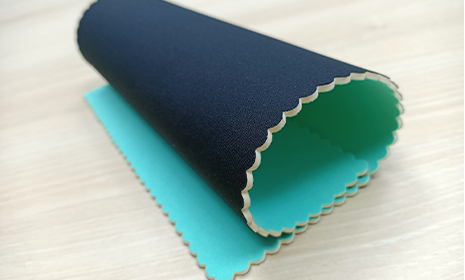

Crisp & Clean Edge

Fine & Precise Incision

Flexible Multi-Shapes Cutting

When cutting industrial foam, the advantages of laser cutter over other cutting tools are obvious. Although the traditional cutter exerts strong pressure on the foam, which results in material deformation and unclean cutting edges, the laser can create the finest contours due to precise and non-contact cutting.

When using water jet cutting, water will be sucked into the absorbent foam during the separation process. Before further processing, the material must be dried, which is a time-consuming process. Laser cutting omits this process and you can continue processing the material immediately. In contrast, the laser is very convincing and is clearly the number one tool for foam processing.

Key Facts you Need to Know about Laser Cutting Foam

Excellent Effect from Laser Cut Foam

▶ Can Laser Cut Foam?

Yes! Laser cutting is renowned for its precision and speed, and CO2 lasers can be absorbed by most non-metallic materials. So, almost all foam materials, such as PS(polystyrene), PES (polyester), PUR (polyurethane), or PE (polyethylene), can be co2 laser cut.

▶ How Thick can a Laser Cut Foam?

In the video, we use the 10mm and 20mm thick foam to make the laser test. The cutting effect is great and obviously the CO2 laser cutting ability is more than that. Technically, the 100W laser cutter is able to cut through 30mm thick foam, so next time let's challenge it!

▶ Is Polyurethane Foam Safe for Laser Cutting?

We use well-functional ventilation and filtration devices, that guarantee safety during laser cutting foam. And there are no debris and fragments you will deal with using the knife cutter to cut foam. So don't worry about the safety. If you have any concerns, inquire us for professional laser advice!

Specifications of the Laser Machine We Use

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W/ |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Make a foam insert for the toolbox and photo frame, or custom a gift made of foam, MimoWork laser cutter can help you to realize all!

Any Question to Laser Cutting & Engraving on Foam?

Let us Know and Offer Further Advice and Solutions for You!

Key Facts you Need to Know about Laser Cutting Foam

So, you’re ready to cut foam, but how do you decide on the best method?

Let’s break it down into a few popular techniques: laser cutting, knife cutting, and water jet cutting. Each has its pros and cons, and knowing them can help you find the best fit for your project.

Laser Cutting Foam

Laser Cutting is often the star of the show.

It offers precision and speed, slicing through foam like butter. The best part?

You get those beautiful, clean edges that make everything look polished.

However, it’s essential to use the right power settings and speeds to avoid burning.

Knife Cutting Foam

Knife Cutting is a classic.

Whether you’re using a utility knife or a hot wire cutter, this method gives you a lot of control.

However, it can be labor-intensive and may lead to less uniform results.

Still, if you enjoy the hands-on approach, this could be the way to go.

Water Jet Cutting Foam

Water Jet Cutting, while less common for foam, can be a game-changer for thicker materials.

It uses high-pressure water mixed with an abrasive to cut through foam without creating heat.

The downside?

It’s often more expensive and requires specialized equipment.

In the end, it all comes down to your project’s needs. Do you want speed and precision? Go with laser cutting. Prefer a more tactile experience? Grab that knife.

Each method has its place in the creative toolbox!

Tips and Tricks for CO2 Laser Cutting Foam

Ready to dive into CO2 laser cutting foam? Here are some handy tips and tricks to help you achieve fantastic results!

Choose the Right Settings

Start with the manufacturer’s recommendations for power and speed.

You might need to adjust these based on the type of foam you’re using, so don’t be afraid to experiment!

Adjust Your Design for Kerf

Remember that the laser has a width (kerf) that will affect your final piece.

Make sure to account for this in your designs to ensure everything fits together perfectly.

Test Cuts Are Your Best Friend

Always do a test cut on a scrap piece of foam.

This helps you tweak the settings before committing to your final design and avoids any costly mistakes.

Ventilation is Key

Cutting foam can produce fumes, especially with certain types.

Make sure you have proper ventilation in your workspace to keep the air fresh and safe.

Focus on Cleanliness

Keep your laser cutter clean and free of debris.

A clean lens ensures optimal performance and helps avoid any unwanted marks on your foam.

Use a Cutting Mat

Placing a cutting mat under your foam.

It can reduce the risk of burning the surface beneath and helps absorb some of the laser’s energy.

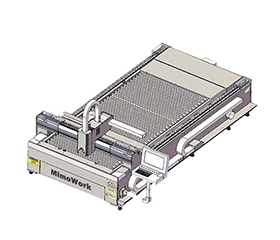

Recommended Laser Foam Cutter Machine

Flatbed Laser Cutter 130

The Mimowork’s Flatbed Laser Cutter 130 is mainly for laser-cutting foam sheets. To cut kaizen foam kit, it's the ideal machine to choose. With the lift platform and large focus lens with a long focal length, the foam fabricator can laser cut the foam board with different thicknesses.

Flatbed Laser Cutter 160 with Extension Table

Especially for laser cutting polyurethane foam and soft foam insert. You can choose different working platforms for different materials...

Flatbed Laser Cutter 250L

The Mimowork’s Flatbed Laser Cutter 250L is R&D for wide textile rolls and soft materials, especially for dye-sublimation fabric and technical textile...

Laser Cut Foam Ideas for Christmas Decor

Dive into the realm of DIY delights as we present a medley of laser-cutting ideas that'll transform your holiday décor. Craft your own personalized photo frames, capturing cherished memories with a touch of uniqueness. Create intricate Christmas snowflakes from craft foam, infusing your space with a delicate winter wonderland charm.

Explore the artistry of versatile ornaments designed for the Christmas tree, each piece a testament to your artistic flair. Illuminate your space with custom laser signs, radiating warmth and festive cheer. Unleash the full potential of laser cutting and engraving techniques to infuse your home with a one-of-a-kind festive ambiance.

Laser Processing for Foam

1. Laser Cutting Polyurethane Foam

Flexible laser head with the fine laser beam to melt the foam in a flash to cut off the foam to achieve sealing edges. It's also the best way to cut soft foam.

2. Laser Engraving on EVA Foam

The fine laser beam etching the surface of the foam board uniformly to achieve optimal engraving effect.

What Foam Results in the Best Result for Laser Cutting?

When it comes to laser cutting foam, the right material can make all the difference.

You may be wondering, “What foam should I choose for my next project?”

Well, let’s dive into the world of foam cutting and uncover the secrets to achieving those crisp, clean edges that make your designs shine.

EVA Foam

EVA Foam is a popular choice, beloved for its versatility and ease of cutting. It's lightweight, comes in various thicknesses, and can be found in an array of colors.

Plus, its flexibility means you can create intricate shapes without worrying about cracking. If you’re planning to make costumes, props, or even craft projects, EVA foam is your go-to buddy!

Polyethylene Foam

Then there's Polyethylene Foam, which is a bit more rigid but extremely durable. This foam is perfect for protective packaging or any application where sturdiness is key.

Cutting it with a laser results in clean edges that won’t fray, giving your project a professional finish.

Polyurethane Foam

Finally, let’s not forget Polyurethane Foam. While it can be a bit trickier to cut—often requiring a bit more finesse—its softness allows for some really unique textures.

If you’re feeling adventurous, experimenting with this foam can lead to spectacular results!

Typical Applications for Laser Cutting Foam

• Foam Gasket

• Foam Pad

• Car Seat Filler

• Foam Liner

• Seat Cushion

• Foam Sealing

• Photo Frame

• Kaizen Foam

Can you Laser Cut EVA Foam?

The answer is a solid YES. High-density foam can be easily cut by laser, so does the other type of polyurethane foams.

This is a material that has been adsorbed by plastic particles, referred to as foam. Foam is divided into rubber foam(EVA foam), PU foam, bulletproof foam, conductive foam, EPE, bulletproof EPE, CR, bridging PE, SBR, EPDM, etc, widely used in life and industry.

Styrofoam is often discussed separately in the BIG Foam Family.

The 10.6 or 9.3-micron wavelength CO2 laser can perform on Styrofoam easily. Laser cutting of Styrofoam comes with clear cutting edges without burning.

FAQ: Laser Cutting Foam

1. Is EVA Foam Safe to Laser Cut?

Absolutely! EVA foam is one of the safest options for laser cutting.

Just make sure to use a well-ventilated area, as it can release some fumes when heated. A little precaution goes a long way in keeping your workspace safe and pleasant!

2. Can Polyethylene Foam be Laser Cut?

Yes, it can!

Polyethylene foam cuts beautifully with a laser, giving you those crisp edges we all love. Just like with EVA foam, ensure your workspace is well-ventilated, and you’re good to go!

3. How do you Cleanly Cut Foam?

For a clean cut, start with the right settings on your laser cutter—power and speed are key!

Always do a test cut first to fine-tune those settings, and consider using a cutting mat to prevent any unwanted burns. With a little practice, you’ll be a foam-cutting pro in no time!

4. Should you Wear a Mask when Cutting Foam?

ALWAYS. It’s a good idea if you’re sensitive to fumes or working in a less-ventilated area.

Keeping a mask handy is just another way to ensure that your creative process remains fun and safe. Better safe than sorry, right?