Laser Cutting Kydex

Kydex is a thermoplastic material renowned for its durability, lightweight nature, and remarkable adaptability. Widely used in various applications—from tactical gear to custom accessories—Kydex has become a go-to choice for manufacturers seeking high-performance materials. One of the most effective methods to work with Kydex is through laser cutting, a technology that not only enhances the material’s applications but also offers numerous benefits over traditional cutting methods.

Kydex Application

What is Kydex?

Kydex is a high-performance thermoplastic composed of a blend of polyvinyl chloride (PVC) and acrylic. This unique combination gives Kydex its impressive qualities:

• Durability: Kydex is designed to withstand impacts, chemicals, and temperature variations, making it suitable for demanding environments.

• Lightweight: Its low weight makes Kydex ideal for products that require comfort and ease of handling, such as holsters and bags.

• Water-Resistant: Kydex's water-resistant properties ensure that it maintains its structural integrity even in wet conditions.

• Ease of Fabrication: Kydex can be easily cut, shaped, and formed, allowing for intricate designs and custom fittings.

Kydex Materials

Who Are We?

MimoWork Laser, an experienced laser cutting machine manufacturer in China, have a professional laser technology team to solve your problems from laser machine selection to operation and maintenance. We have been researching and developing various laser machines for different materials and applications. Check out our laser cutting machines list to get an overview.

The Advantages of Laser Cutting Kydex

1. Exceptional Precision and Accuracy

Laser cutting is renowned for its precision.The focused beam of the laser allows for intricate designs and complex shapes to be cut with astonishing accuracy.This is particularly important in applications like firearm holsters, where a snug fit is crucial for safety and functionality.The ability to achieve such detailed cuts means that manufacturers can create custom designs tailored to specific needs.

5. Enhanced Design Flexibility

The heat generated during laser cutting helps seal the edges of Kydex, minimizing fraying and enhancing the overall durability of the product.This is especially important for items that experience frequent use, as sealed edges maintain the integrity and appearance of the final product.The result is a cleaner, more polished look that appeals to consumers.

2. Minimal Material Waste

One of the significant advantages of laser cutting is its efficiency. Unlike traditional cutting methods, which often produce a considerable amount of scrap material, laser cutting generates clean cuts that minimize waste. This optimization not only reduces material costs but also aligns with sustainability efforts by making the most out of every sheet of Kydex.

6. Automation and Scalability

The heat generated during laser cutting helps seal the edges of Kydex, minimizing fraying and enhancing the overall durability of the product. This is especially important for items that experience frequent use, as sealed edges maintain the integrity and appearance of the final product. The result is a cleaner, more polished look that appeals to consumers.

3. Speed of Production

In a competitive manufacturing landscape, speed is essential. Laser cutting dramatically reduces production times compared to manual or mechanical methods. With the ability to execute multiple cuts in a fraction of the time, manufacturers can meet tight deadlines and respond quickly to customer demands. This efficiency enables businesses to scale up production without compromising on quality.

4. Reduced Fraying and Edge Sealing

The heat generated during laser cutting helps seal the edges of Kydex, minimizing fraying and enhancing the overall durability of the product. This is especially important for items that experience frequent use, as sealed edges maintain the integrity and appearance of the final product. The result is a cleaner, more polished look that appeals to consumers.

7. Reduced Labor Costs

With the automation capabilities of laser cutting, manufacturers can reduce labor costs significantly. Fewer personnel are needed for the cutting process, allowing staff to focus on other critical areas of production. This efficiency translates to cost savings that can be redirected towards other business needs.

Kydex Knives and Sheaths

A Few Highlights of Laser Cutting Machine >

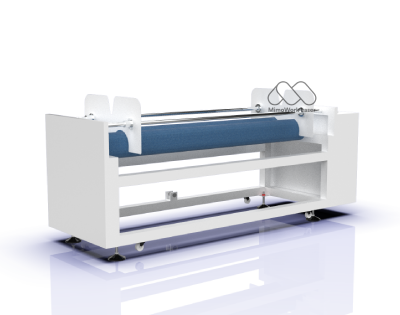

For roll materials, the combination of auto-feeder and conveyor table is an absolute advantage. It can automatically feed the material onto the working table, smoothing the whole workflow. Saving time and guaranteeing the material flat.

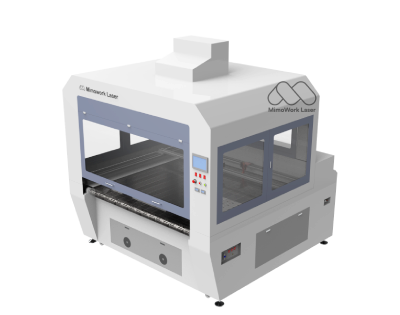

The fully enclosed structure of laser cutting machine is designed for some clients with higher requirements for safety. It prevent the operator from directly contact with the working area. We specially installed the acrylic window so that you can monitor the cutting condition inside.

To absorb and purify the waste fume and smoke from laser cutting. Some composite materials have chemical content, that can release the pungent odor, in this case, you need a great exhaust system.

Recommended Fabric Laser Cutter for Kydex

• Laser Power: 100W / 150W / 300W

• Working Area: 1600mm * 1000mm

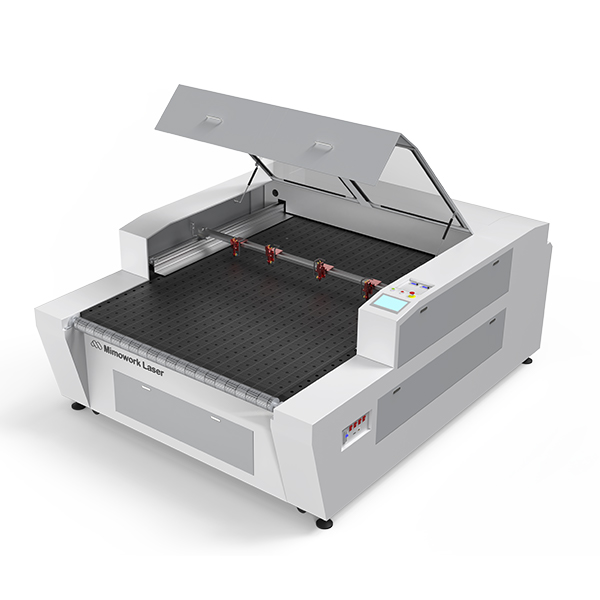

Flatbed Laser Cutter 160

Fitting the regular clothing and garment sizes, the fabric laser cutter machine has a working table of 1600mm * 1000mm. The soft roll fabric is pretty suitable for laser cutting. Except that, leather, film, felt, denim and other pieces can all be laser cut thanks to the optional working table. The steady structure is the base of production...

• Laser Power: 100W/150W/300W

• Working Area: 1800mm * 1000mm

Flatbed Laser Cutter 180

To meet more varieties of cutting requirements for fabric in different sizes, MimoWork widens the laser cutting machine to 1800mm * 1000mm. Combined with the conveyor table, roll fabric and leather can be allowed to convey and laser cutting for fashion and textiles without interruption. In addition, multi-laser heads are accessible to enhance the throughput and efficiency...

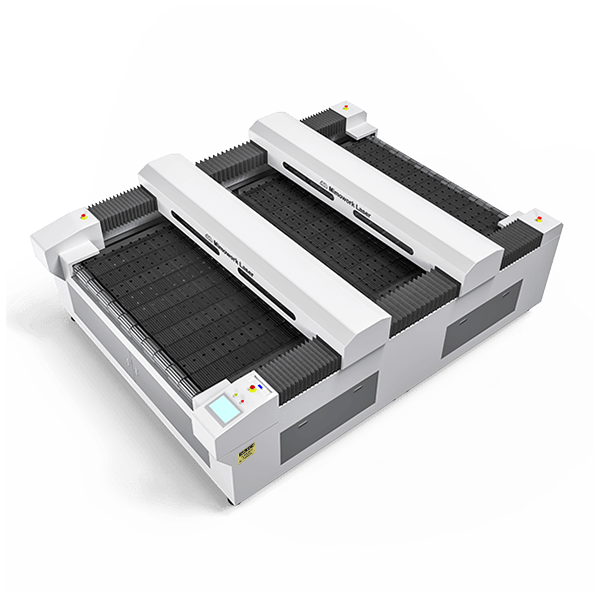

• Laser Power: 150W / 300W / 450W

• Working Area: 1600mm * 3000mm

Flatbed Laser Cutter 160L

The MimoWork Flatbed Laser Cutter 160L, characterized by the large-format working table and higher power, is widely adopted for cutting industrial fabric and functional clothing. Rack & pinion transmission and servo motor-driven devices provide steady and efficient conveying and cutting. CO2 glass laser tube and CO2 RF metal laser tube are optional...

• Laser Power: 150W / 300W / 450W

• Working Area: 1500mm * 10000mm

10 Meters Industrial Laser Cutter

The Large Format Laser Cutting Machine is designed for ultra-long fabrics and textiles. With a 10-meters long and 1.5-meters wide working table, the large format laser cutter is suitable for most fabric sheets and rolls like tents, parachutes, kitesurfing, aviation carpets, advertising pelmet and signage, sailing cloth and etc. Equipped with a strong machine case and a powerful servo motor...

Other Traditional Cutting Methods

Manual Cutting: Often involves using scissors or knives, which can lead to inconsistent edges and require significant labor.

Mechanical Cutting: Uses blades or rotary tools but may struggle with precision and produce frayed edges.

Limitation

Precision Issues: Manual and mechanical methods can lack the accuracy needed for intricate designs, leading to material waste and potential product defects.

Fraying and Material Waste: Mechanical cutting can cause the fibers to fray, compromising the fabric's integrity and increasing waste.

Select One Laser Cutting Machine Suitable for Your Production

MimoWork is here to offer professional advice and suitable laser solutions !

Applications of Laser-Cut Kydex

Firearm Holsters

Custom-fit holsters for firearms benefit immensely from the precision of laser cutting, ensuring safety, accessibility, and comfort.

Knives and Sheaths

Kydex sheaths for knives can be designed to fit specific blade shapes, providing both protection and aesthetic appeal.

Tactical Gear

Various tactical accessories, such as magazine pouches, utility holders, and custom fittings, can be efficiently produced with laser-cut Kydex, enhancing functionality and user experience.

Related Materials to Kydex can be Laser Cut

Carbon Fiber Composites

Carbon fiber is a strong, lightweight material used in aerospace, automotive, and sports equipment.

Laser cutting is effective for carbon fiber, allowing for precise shapes and minimizing delamination. Proper ventilation is essential due to fumes generated during cutting.

Kevlar®

Kevlar is an aramid fiber known for its high tensile strength and thermal stability. It is widely used in bulletproof vests, helmets, and other protective gear.

While Kevlar can be laser cut, it requires careful adjustment of laser settings due to its heat resistance and potential to char at higher temperatures. The laser can provide clean edges and intricate shapes.

Nomex®

Nomex is another aramid fiber, similar to Kevlar but with added flame resistance. It is used in firefighter clothing and racing suits.

Laser cutting Nomex allows for precise shaping and edge finishing, making it suitable for protective apparel and technical applications.

Spectra® Fiber

Similar to Dyneema and X-Pac fabric, Spectra is another brand of UHMWPE fiber. It shares comparable strength and lightweight properties.

Like Dyneema, Spectra can be laser cut to achieve precise edges and prevent fraying. Laser cutting can handle its tough fibers more efficiently than traditional methods.

Vectran®

Vectran is a liquid crystal polymer known for its strength and thermal stability. It is used in ropes, cables, and high-performance textiles.

Vectran can be laser cut to achieve clean and precise edges, ensuring high performance in demanding applications.

Cordura®

Usually made of nylon, Cordura® is regarded as the toughest synthetic fabric with unparalleled abrasion resistance, tear resistance, and durability.

CO2 laser features high energy and high precision, and can cut through Cordura fabric at a fast speed. The cutting effect is great.

We have made a laser test using 1050D Cordura fabric, check out the video to find out.