Custom Laser Cut Patch Solutions | Precision & Speed

The Trend of Laser Cutting Patch

Custom laser cut patch offers clean edges and high precision, ideal for detailed designs on fabric, leather, and embroidery.

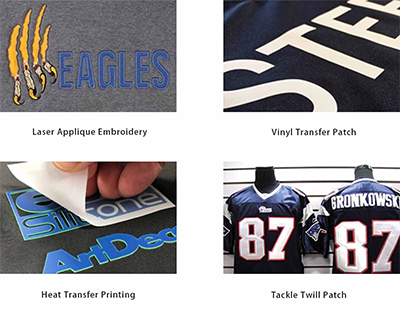

Nowadays, vibrant patches keep up with the customization trend, evolving into diverse types like embroidery patches, heat transfer patches, woven patches, reflective patches, leather patches, PVC patches, and more.

Laser cutting, as a versatile and flexible cutting method, can deal with the patches of various types and materials. Laser cut patch features high quality and intricate design, bring new vitality and opportunities for patches and accessories market.

Laser cutting patches is with high automation and can handle the batch production in a fast speed. Also, the laser machine excels in cutting customized patterns and shapes, that make laser cutting patches is suitable for high-end designers.

Patch Laser Cutting

Laser cutting opens up versatile options for creating high-quality laser cut patch products, including embroidery, leather, and Velcro patches. This technique ensures precise shapes, sealed edges, and material flexibility—ideal for customized branding, fashion, or tactical use.

From MimoWork Laser Machine Series

Video Demo: Laser Cut Embroidery Patch

CCD Camera Laser Cutting Patches

- Mass Production

CCD Camera auto recognizes all the patterns and match with the cutting outline

- High Quality Finishing

Laser Cutter realizes in clean and accurate pattern cutting

- Saving Time

Convenient to cut the same design next time by saving the template

Benefits from Laser Cutting Patch

Smooth & clean edge

Kiss cutting for multi-layers materials

laser leather patches of <br>Intricate engraving pattern

✔ Vision system helps accurate pattern recognition and cutting

✔ Clean and sealed edge with the heat treatment

✔ Powerful laser cutting ensures no adhesion between materials

✔ Flexible and fast cutting with auto-template matching

✔ Ability to cut complex pattern into any shapes

✔ No post-processing, saving cost and time

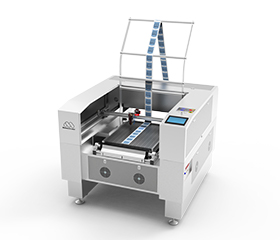

Patch Cutting Laser Machine

• Laser Power: 50W/80W/100W

• Working Area: 900mm * 500mm (35.4” * 19.6”)

• Laser Power: 100W / 150W / 300W

• Working Area: 1600mm * 1000mm (62.9’’ * 39.3’’)

• Laser Power: 60w

• Working Area: 400mm * 500mm (15.7” * 19.6”)

How to Make Laser Cut Patches?

To achieve premium quality and high efficiency when producing patches, the laser cut patch method is an ideal solution. Whether it’s an embroidery patch, printed patch, or woven label, laser cutting offers a modern heat-fuse technique that surpasses traditional manual cutting.

Unlike manual methods that require controlling blade direction and pressure, laser cutting is fully guided by a digital control system. Simply import the correct cutting parameters, and the laser cutter will precisely handle the process—delivering clean edges and consistent results.

The overall cutting process is simple, efficient, and perfect for high-quality laser cut patch production.

Step1. Prepare the Patches

Put your format of patch on the laser cutting table, and ensure the material is flat, with no warping.

Step2. CCD Camera Takes the Photo

The camera laser machine uses a CCD camera to capture images of the patches. Then, the software automatically detects and identifies the key feature areas of the patch pattern.

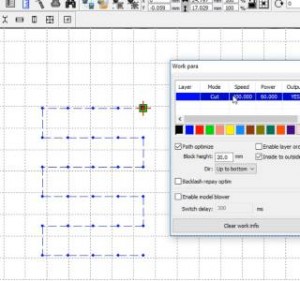

Step3. Simulate the Cutting Path

Import your cutting file, and match the cutting file with the featured area extracted by the camera. Click the simulate button, you will get the whole cutting path in the software.

Step4. Start Laser Cutting

Start the laser head, the laser cutting patch will continue until finished.

Laser Cut Patch Types

Print Patches

- Vinyl Patches

Waterproof and flexible patches made from vinyl, ideal for outdoor or sporty designs.

- Leather Patches

Made from genuine or synthetic leather, offering a premium and rugged look.

- Hook and Loop Patch

Features detachable backing for easy reuse and position adjustment.

- Heat Transfer Patches (Photo Quality)

Use heat to apply high-resolution, photo-like images directly onto fabric.

- Reflective patches

Reflect light in the dark for increased visibility and safety.

- Embroidered Patches

Made with stitched threads to create textured, traditional designs.

Use fine threads for detailed, flat designs, ideal for brand labels.

- PVC Patches

Durable, flexible rubber patches with vibrant colors and 3D effect.

- Velcro Patches

Easy to attach and remove using hook-and-loop fasteners.

- Iron on Patches

Applied with heat using a household iron, offering easy DIY attachment.

- Chenille Patches

Applied with heat using a household iron, offering easy DIY attachment.

More Materials Information about Laser Cutting

The versatility of patches is showcased through advancements in materials and techniques. In addition to traditional embroidery patches, technologies like heat transfer printing, patch laser cutting, and laser engraving expand creative options.

The camera laser machine, known for precise cutting and real-time edge sealing, ensures high-quality patch production. With optical recognition, it achieves accurate pattern alignment and enhances cutting precision—ideal for custom designs.

To fulfill both functional needs and aesthetic goals, techniques such as laser engraving, marking, and kiss-cutting on multi-layer materials offer flexible processing. Using a laser cutter, you can easily produce laser cut flag patches, laser cut police patches, laser cut velcro patches, and other custom tactical patches.

FAQ

Absolutely! Laser cutting roll woven labels is completely achievable. In fact, the laser cutting machine is capable of processing nearly all types of patches, labels, stickers, tags, and fabric accessories.

For roll woven labels specifically, we've developed an auto-feeder and conveyor table system, which significantly improves both cutting efficiency and precision.

Want to know more about laser cutting roll woven labels?

Check this page out: How to laser cut roll woven label.

Yes, the laser cut patches process is excellent for handling complex designs and fine details. Thanks to the precision of the laser beam and the digital control system, it can accurately cut intricate patterns with clean edges that traditional cutting methods often cannot achieve. This makes laser cutting ideal for custom patches requiring detailed graphics and sharp contours.

Yes, laser cut patches can easily be integrated with Velcro or iron-on backing to allow for simple and convenient application. The precision of laser cutting ensures clean edges that fit perfectly with Velcro hook-and-loop systems or heat-activated iron-on adhesives, making the patches versatile and user-friendly for attachment and removal.