Introduction Of Laser Cutting Skisuit

Skiing is being loved by more and more people nowadays. What this sport brings to people is a combination of leisure and racing. In the cold winter, it's so exciting to wear ski suits with bright colors and various high-tech fabrics to go to the ski resort.

Have you ever thought about how colorful and warm ski suits are made? How does the fabric laser cutter custom cut sik suit and other outdoor apparels? Follow the experience of MimoWork to know about that.

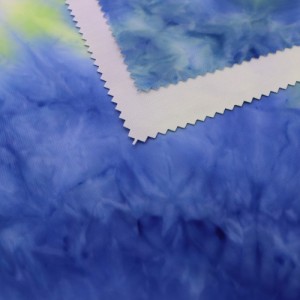

First of all, the current ski suits are all brightly colored. Many ski suits are offering personalized color options, customers can choose the color according to their preferences. This is due to the current clothing printing technology, manufacturers can apply dye-sublimation printing methods to provide customers with the most colorful colors and graphics.

Professional Fabric Cutting Machines - Fabric Laser Cutter

That just fits in the advantages of sublimation laser cutting. Due to the laser-friendly of fabric and vision recognition system, the contour laser cutter can achieve perfect outdoor apparel laser cutting as pattern contour. Non-contact fabric laser cutting keeps the fabric intact and no distortion, which provides excellent clothing quality as well as great functionality. Plus with custom fabric cutting is always the strength of flexible laser cutting. The laser fabric pattern cutting machine is your best choice for cutting ski suit.

Benefits From Fabric Laser Cutting On Skisuit

1. No Cutting Deformation

The biggest advantage of laser cutting is non-contact cutting, which makes it no tools will contact the fabric when cutting like knifes. It results that no cutting errors caused by pressure acting on the fabric will occur, highly improving quality strategy in the production.

2. Cutting Edge

Due to the heat treatments process of laser, the spandex fabric is virtually melted into the piece by laser. The advantage will be that the cut edges are all treated and sealed with high temperature, without any lint or blemish, which determines to achieve the best quality in one processing, no need for rework to spend more processing time.

3. High Degree Of Accuracy

Laser cutters are CNC machine tools, every step of the laser head operation is calculated by the motherboard computer, which makes cutting more precise. Matching with an optional camera recognition system, the cutting outlines of printed spandex fabric can be detected by laser to achieve higher accuracy than the traditional cutting method.

How To Cut Ski Suit Fabric By A Laser Cutter?

Cut And Mark Fabric For Sewing

Step into the future of fabric crafting with the CO2 Laser Cut Fabric Machine – a true game-changer for sewing enthusiasts! Wondering how to cut and mark fabric seamlessly? Look no further.

This all-around fabric laser cutting machine hits it out of the park by not only cutting fabric with precision but also marking it for a touch of personalized flair. And here's the kicker – cutting notches in fabric for your sewing projects becomes as easy as a laser-powered walk in the park. The digital control system and automatic processes transform the entire workflow into a breeze, making it a perfect fit for clothing, shoes, bags, and other accessories.

Auto Feeding Laser Cutting Machine

Get ready to revolutionize your fabric designs with the auto-feeding laser-cutting machine – your ticket to automatic and highly efficient laser-cutting glory! Whether you're grappling with long fabric lengths or rolls, the CO2 laser cutting machine has got your back. It's not just about cutting; it's about precision, ease, and unlocking a realm of creativity for fabric enthusiasts.

Imagine the seamless dance of auto-feeding and auto-cutting, working in tandem to elevate your production efficiency to laser-powered heights. Whether you're a beginner venturing into the fabric wonderland, a fashion designer seeking flexibility, or an industrial fabric manufacturer craving customization, our CO2 laser cutter emerges as the superhero you never knew you needed.

Recommended Laser Cutting Machine For Skisuit

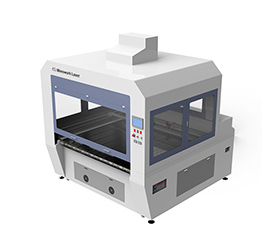

Contour Laser Cutter 160L

Sublimation Laser Cutter

Contour Laser Cutter 160L is equipped with an HD Camera on the top which can detect the contour…

Contour Laser Cutter-Fully Enclosed

Digital Fabric Cutting Machine, Improved Safety

The fully enclosed structure is added to the conventional Vision Laser Cutting Machine....

Flatbed Laser Cutter 160

Fabric Laser Cutter

Especially for textile & leather and other soft materials cutting. Different working platforms...

Skisuit Materials Of Garment Laser Cutting

Usually, ski suits are not made of one thin layer of fabric, but a variety of expensive high-tech fabrics are used inside to form a garment that provides strong warmth. So for manufacturers, the cost of such fabric is extremely expensive. How to optimize the cutting effect of the cloth and how to minimize the loss of materials has become a problem that everyone wants to solve most. So now most manufacturers have begun to use modern cutting methods to replace labor, which will also greatly reduce their production costs, not only raw material cost but also labor cost.

Skiing is experiencing a surge in popularity, captivating the hearts of more and more people today. This exhilarating sport combines leisure with a touch of competition, making it a sought-after activity in the cold winter months. The thrill of adorning ski suits in vibrant hues and cutting-edge high-tech fabrics to venture to the ski resort adds to the excitement.

Have you ever pondered the fascinating process of creating these colorful and warm ski suits? Enter the world of fabric laser cutting and witness how the fabric laser cutter customizes ski suits and other outdoor apparel, all under the guidance of MimoWork's expertise.

Modern ski suits dazzle with their brightly colored designs, and many even offer personalized color options, allowing customers to express their individual style. The credit for such vibrant designs goes to cutting-edge clothing printing technology and dye-sublimation methods, enabling manufacturers to offer an impressive array of colors and graphics. This seamless integration of technology perfectly complements the advantages of sublimation laser cutting.

Related Materials

FAQ

No, laser cutting (especially CO₂ lasers) rarely damages stretchy skisuit fabric. Here’s why:

CO₂ Lasers (Best for Skisuit Fabrics):

Wavelength (10.6μm) matches stretchy fibers (spandex/nylon).

Non - contact cutting + heat - sealed edges = no fraying or distortion.

Fiber Lasers (Risky for Stretchy Fabrics):

Wavelength (1064nm) poorly absorbs by stretchy fibers.

May overheat/melt fabric, damaging elasticity.

Settings Matter:

Use low power (30–50% for spandex) + air assist to avoid burns.

In short: CO₂ lasers (proper settings) safely cut—no damage. Fiber lasers risk harm. Test scraps first!

Yes, but it depends on production scale. Here’s why:

Auto - Feeding Machines:

Ideal for long skisuit rolls (100+ meters) and mass production. Automatically feeds fabric, saving time and reducing errors—key for factories.

Manual/Flatbed Cutters:

Work for short rolls (1–10 meters) or small batches. Operators load fabric by hand—cheaper for local shops/bespoke orders.

Key Factors:

Fabric Type: Stretchy skisuit materials need steady feeding—auto - feed prevents slipping.

Cost: Auto - feed adds cost but cuts labor time for big jobs.

In short: Auto - feeding is “needed” for large - scale roll cutting (efficiency). Small batches use manual setups!

es, setup depends on software and laser features. Here’s why:

Design Software (Illustrator, CorelDRAW):

Create your pattern, then export as SVG/DXF (vector formats preserve precision).

Laser Software:

Import the file, adjust settings (power/speed for skisuit fabric like spandex).

Use the machine’s camera system (if available) to align with printed designs.

Prep & Test:

Lay fabric flat, run a test cut on scraps to refine settings.

In short: Design → export → import to laser software → align → test. Simple for custom skisuit patterns!