Laser Cutting Softshell Jacket

Get away from the cold, rain and maintain an ideal body temperature with just one garment?!

With softshell fabric clothing you can!

Material Information of Laser Cutting Softshell Jacket

Soft shell in English is called "SoftShell Jacket", so the name is inconceivable "soft jacket ", refers to a technical fabric designed to ensure maximum comfort in changeable weather conditions. Usually the softness of the fabric is far better than the hard shell, and some fabrics also have a certain elasticity. It integrates some functions of the previous hardshell jacket and fleece, and takes into account water resistance while doing wind protection, warmth and breathability - the soft shell has DWR waterproof treatment coating. Clothing fabric suitable for climbing and long hours of physical labor.

It Is not a Raincoat

In general, the more waterproof a garment is, the less breathable it is. The biggest problem that outdoor sports lovers have found with waterproof clothing is the moisture trapped inside jackets and trousers. The advantage of the waterproofing clothes is annulled in conditions of rain and cold and when you stop to rest the sensation becomes uncomfortable.

The softshell jacket, on the other hand, was created specifically to facilitate the release of moisture and regulate body temperature. For this reason, the outer layer of the softshell can not be waterproof, but water-repellent, thus ensuring in wearing it to remain dry and protected.

How It’s Made

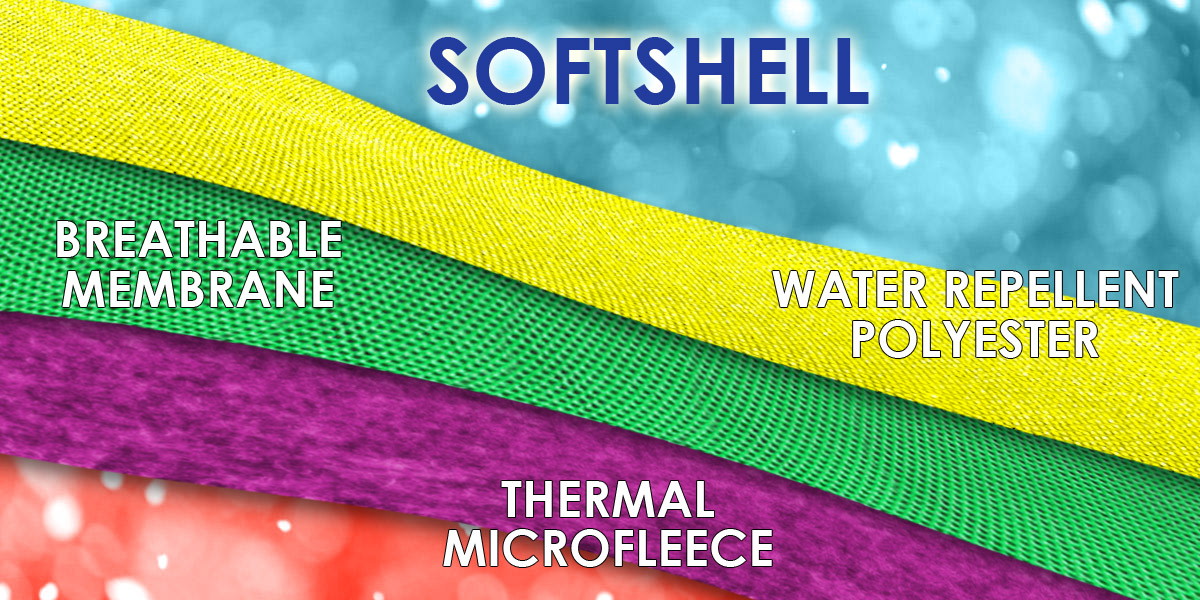

The softshell jacket is composed of three layers of different materials, which guarantee excellent performance:

• The outer layer is in high density water repellent polyester, which provides the garment with good resistance to external agents, with rain or snow.

• The middle layer is instead a breathable membrane, thus allowing moisture to escape, without stagnating or wetting the interior.

• The inner layer is made of microfleece, which ensures good thermal insulation and is pleasant to contact with the skin.

The three layers are coupled, thus becoming a very light, elastic and soft material, which offers resistance to wind and weather, maintaining good breathability and freedom of movement.

Are all Softshells the Same?

The answer, of course, is no.

There are softshells that guarantee different performances and it is important to know them before buying a garment made with this material. The three key features, which measure the quality of a softshell jacket product, are water repellency, wind resistance and breathability.

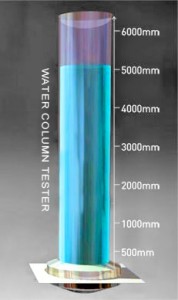

Water Column Tester

By placing a graduated column on the fabric, it is filled with water to determine the pressure at which the material is permeated. For this reason the impermeability of a fabric is defined in millimeters. Under normal conditions, rainwater pressure ranges between 1000 and 2000 millimetres. Above 5000mm the fabric offers excellent levels of water resistance, although it is not completely waterproof.

Air Permability Test

It consists in measuring the amount of air that permeates a fabric sample, using special equipment. The permeability percentage is normally measured in CFM (cubic feet/minute), where 0 represents the perfect insulation. It should therefore be considered in relation to the breathability of a fabric.

Breathability Test

It measures how much water vapour passes through a 1 square metre portion of fabric in a 24-hour period, and is then expressed in MVTR (Moisture vapour transmission rate). A value of 4000 g/M2/24h is therefore higher than 1000 g/M2/24h and is already a good level of transpiration.

MimoWork provides different working tables and optional vision recognition systems contribute to laser cutting varieties of softshell fabric items, whether any size, any shape, any printed pattern. Not only that, each laser cutting machine is precisely adjusted by MimoWork’s technicians before leaving factory so that you can receive the best-performing laser machine.

How to Cut Softshell Jacket with the Fabric Laser Cutting Machine?

The CO₂ laser, with wavelengths of 9.3 and 10.6 microns, is effective for cutting softshell jacket fabrics like nylon and polyester. Additionally, laser cutting and engraving offer designers more creative possibilities for customization. This technology continues to innovate, meeting the growing demands for detailed and functional outdoor gear designs.

Benefits from Laser Cutting Softshell Jacket

Tested & Verfied by MimoWork

Clean edges at all angles

Stable and repeatable cutting quality

Large format cutting is possible

✔ No cutting deformation

The biggest advantage of laser cutting is non-contact cutting, which makes it no tools will contact the fabric when cutting like knifes. It results that no cutting errors caused by pressure acting on the fabric will occur, highly improving quality strategy in the production.

✔ Cutting edge

Due to the heat treatments process of laser, the softshell fabric is virtually melted into the piece by laser. The advantage will be that the cut edges are all treated and sealed with high temperature, without any lint or blemish, which determines to achieve the best quality in one processing, no need for rework to spend more processing time.

✔ High degree of accuracy

Laser cutters are CNC machine tools, every step of the laser head operation is calculated by the motherboard computer, which makes cutting more precise. Matching with an optional camera recognition system, the cutting outlines of softshell jacket fabric can be detected by laser to achieve higher accuracy than the traditional cutting method.

Laser Cutting Skiwear

This video demonstrates how laser cutting can be used to create ski suits with complex patterns and custom designs to ensure a perfect fit and optimum performance on the ski slopes. The process involves cutting soft shells and other technical fabrics using high-power CO₂ lasers, resulting in seamless edges and less material waste.

The video also highlights the benefits of laser cutting, such as improved water resistance, air permeability and flexibility, which are essential for skiers facing challenging winter conditions.

Auto Feeding Laser Cutting Machine

This video showcases the remarkable flexibility of a laser-cutting machine specifically designed for textiles and apparel. The laser cutting and engraving machine offers precision and ease of use, making it ideal for a wide range of fabrics.

When it comes to the challenge of cutting long or roll fabric, the CO2 laser cutting machine (1610 CO2 laser cutter) stands out as the perfect solution. Its automated feeding and cutting capabilities significantly enhance production efficiency, providing a smooth and efficient experience for everyone from beginners to fashion designers and industrial fabric producers.

Recommended CNC Cutting Machine for Softshell Jacket

Contour Laser Cutter 160L

Contour Laser Cutter 160L is equipped with an HD Camera on the top which can detect the contour and transfer the cutting data to the laser directly....

Contour Laser Cutter 160

Equipped with a CCD camera, Contour Laser Cutter 160 is suitable for processing high precision twill letters, numbers, labels…

Flatbed Laser Cutter 160 with extension table

Especially for textile & leather and other soft materials cutting. You can choose different working platforms for different materials...

Laser Processing for Shortshell Jacket

1. Laser Cutting Shotshell Jacket

• Secure the fabric: Lay the softshell fabric flat on the worktable and secure it with clamps.

• Import the design: Upload the design file to the laser cutter and adjust the pattern's position.

• Start cutting: Set the parameters according to the fabric type and start the machine to complete the cut.

2. Laser Engraving on Shotshell Jacket

• Align the pattern: Fix the jacket on the worktable and use the camera to align the design pattern.

• Set parameters: Import the engraving file and adjust the laser parameters based on the fabric.

• Execute engraving: Start the program, and the laser engraves the desired pattern on the jacket surface.

3. Laser Perforating on Shotshell Jacket

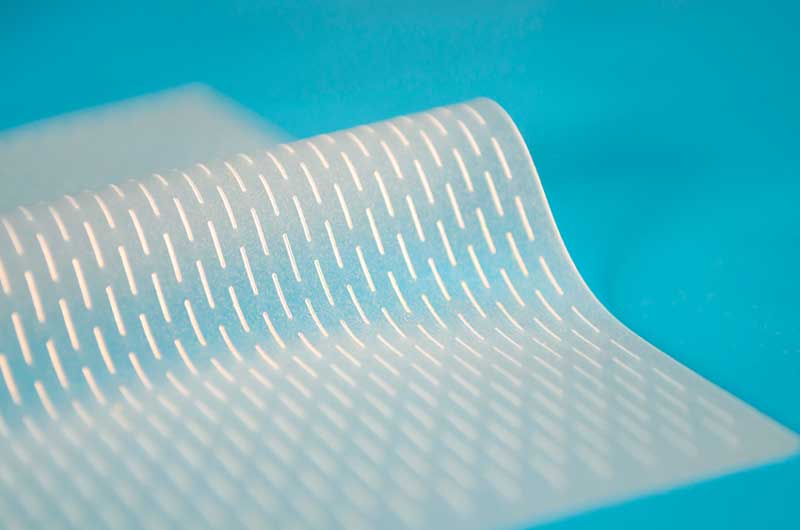

Laser drilling technology can quickly and accurately create dense and diverse holes in softshell fabrics for complex designs. After aligning the fabric and pattern, import the file and set parameters, then start the machine to achieve clean drilling without post-processing.

Typical applications for Laser Cutting Softshell Fabrics