Functional Garment Laser Cutting

Fabric Laser Cutting Machine For Technical Clothing

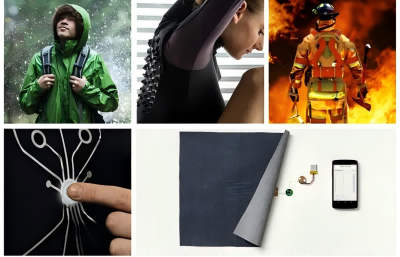

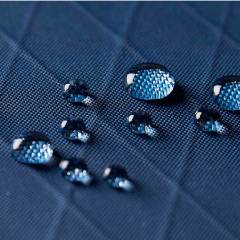

While enjoying the fun brought by outdoor sports, how can people protect themselves from the natural environment such as wind and rain? Laser cutter system provides a new contactless process scheme for the outdoor equipments like functional clothing, breathable jersey, waterproof jacket and others. To optimize the protection effect to our body, these fabrics performance need to be maintained during fabric cutting. Fabric laser cutting is charactered with non-contact treatment and eliminates the cloth distortion and damage.

Also that extend the service life of the laser head. Inherent thermal processing can timely sealing the fabric edge while garment laser cutting. Base on these, most technical fabric and functional apparel manufacturers are gradually replacing the traditional cutting tools with the laser cutter to achieve higher production capacity.

Current clothing brands not only pursue style but also require the use of functional clothing materials to provide users with a more outdoor experience. This makes traditional cutting tools no longer meet the cutting needs of new materials. MimoWork is dedicated to researching new functional clothing fabrics and providing the most suitable cloth laser cutting solutions for sportswear processing manufacturers.

In addition to the new polyurethane fibers, our laser system can also specifically process other functional clothing materials: Polyester, Polypropylene ,Polyamide. Especially Courdura®, a common fabric from outdoor equipment and functional clothing, are popular among military and sports enthusiasts. Laser cutting Cordura® is gradually accepted by fabrics manufacturers and individuals due to fabric laser cutting's high precision, heat treatment to seal edges and high efficiency, etc.

Advantages Of Garment Laser Cutting Machine

Clean & Smooth Edge

Cut Any Shape You Want

✔ Save tool cost and labor cost

✔ Simplify your production, automatic cutting for roll fabrics

✔ High output

✔ No required the original graphics files

✔ High precision

✔ Continuous auto-feeding and processing through Conveyor Table

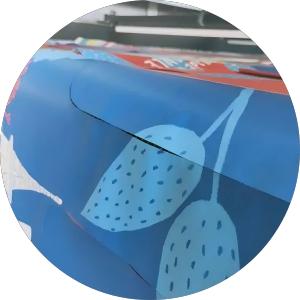

✔ Accurate pattern cutting with Contour Recognition System

How To Laser Cut Technical Fabric | Video Display

Demonstration Of Laser Cut Cordura

Get ready for a laser-cutting extravaganza as we put Cordura to the test in our latest video! Wondering if Cordura can handle the laser treatment? We've got the answers for you. Watch as we dive into the world of laser cutting 500D Cordura, showcasing the results and addressing common questions about this high-performance fabric. But that's not all – we're taking it up a notch by exploring the realm of laser-cut Molle plate carriers.

Find out how the laser adds precision and finesse to these tactical essentials. The video is not just about cutting; it's a journey into the possibilities that laser technology unveils for Cordura and beyond. Stay tuned for the laser-powered revelations that will leave you in awe!

How To Make Money With A CO2 Laser Cutter

Why choose the sportswear business, you ask? Brace yourself for some exclusive secrets straight from the source manufacturer, revealed in our video that's a treasure trove of knowledge.

Need a success story? We've got you covered with a case sharing how someone built a 7-figure fortune in the custom sportswear business, involving sublimation printing, cutting, and sewing. Athletic apparel has a colossal market, and sublimation printing sportswear is the trendsetter. Equip yourself with digital printing machines and camera laser cutting machines, and watch as automatic printing and cutting sportswear turn on-demand requirements into massive profits with super-high efficiency.

>> Find more videos about our laser cutters at our Video Gallery

Laser Cut Clothing Machine Recommendation

• Laser Power: 100W/150W/300W

• Working Area: 1600mm * 3000mm (62.9’’ *118’’)

Functional Fabric Application

• Sportswear

• Medical Textiles

• Protective Clothing

• Smart Textiles

• Automotive Interiors

• Home Textiles

• Fashion and Apparel