Fabric (Textile) Laser Cutting

Introduction Of Laser Cutting Fabric

Fabric laser cutting is a precise method that uses a laser beam to cut fabrics with high accuracy. It creates clean, smooth edges without fraying, making it ideal for intricate designs in industries like fashion and upholstery. This technique is fast, reduces material waste, and can handle various fabrics, offering high precision for both custom and mass production.

Laser cutting plays an important role in cutting natural and synthetic fabrics. With wide materials compatibility, natural fabrics like silk, cotton, linen cloth can be laser cut meanwhile retaining themselves non-damaged in intactness and properties.

>> More Fabrics Can Be Laser Cutting

Advantages Of Laser Cutting Fabric

Synthetic fabrics and natural fabrics can be laser cut with high precision and high quality. By heat melting the fabric edges, the fabric laser cutting machine can bring you an excellent cutting effect with a clean & smooth edge. Also, no fabric distortion occurs thanks to contactless laser cutting.

Clean & Smooth edge

Flexible Shape Cutting

✔ Perfect Cutting Quality

1. Clean and smooth cutting edge thanks to the laser heat cutting, no need for post-trimming.

2. The fabric will not be crushed or distorted due to contactless laser cutting.

3. A fine laser beam (less than 0.5mm) can achieve complex and intricate cutting patterns.

4. The MimoWork vacuum working taable offers strong adhesion to the fabric, keeping it flat.

5. Powerful laser power can handle heavyweight fabrics like 1050D High-Tenacity Nylon Fabric。

✔ High Production Efficiency

1. Automatic feeding, conveying, and laser cutting smooth and speed up the full production process.

2. Intelligent MimoCUT software simplifies the cutting process, offering the optimal cutting path. Accurate cutting, no manual error.

3. Specially designed multiple laser heads increase the cutting and engraving efficiency.

4. The extension table laser cutter provides a collection area for timely collecting while laser cutting.

✔ Versatility & Flexibility

1. CNC system and precise laser processing enable tailor-made production.

2. Varieties of composite fabrics and natural fabrics can be perfectly laser cut.

3. Laser engraving and cutting fabric can be realized in one fabric laser machine.

4. Intelligent system and humanized design make operation easy, suitable for beginners.

Laser Technique For Solid Color Fabric

▍Laser Cutting Solid Color Fabric

Advantages

✔ No crushing and breaking of material due to contactless processing

✔ Laser thermal treatments guarantee no fraying edges

✔ Engraving, marking, and cutting can be realized in a single processing

✔ No materials fixation thanks to MimoWork vacuum working table

✔ Automatic feeding allows unattended operation which saves your labor cost, the lower rejection rate

✔ The advanced mechanical structure allows laser options and customized working table

Applications:

Clothing, Mask, Interior (Carpets, Curtains, Sofas, Armchairs, Textile Wallpaper), Technical Textiles (Automotive, Airbags, Filters,Air Dispersion Ducts )

Video 1 : Laser Cutting Clothing (Plaid Shirt)

Video 2 : Laser Cutting Cotton Fabric

▍Laser Etching Solid Color Fabric

Advantages

✔ Voice Coil Motor delivers maximum marking speed up to 15,000mm's

✔ Automatic feeding & cutting due to Auto-Feeder and Conveyor Table

✔ Continuous high speed and high precision ensure productivity

✔ Extensible Working Table can be customized in accord with material format

Video: Laser Engraving & Cutting Alcantara

▍Laser Perforating Solid Color Fabric

Advantages

✔ No dust or contamination

✔ High-speed cutting for plenty of holes within a short time

✔ Precise cutting, perforating, micro perforating

Video: Laser Cutting Holes In Fabric - Roll To Roll

Laser is computer-controlled realizes easily switching in any perforated fabric with different design layouts. Because the laser is non-contact processing, it will not deform the fabric when punching expensive elastic fabrics. Since the laser is heat-treated, all cutting edges will be sealed which ensures smooth cutting edges.

Recommended Textile Laser Cutter

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Laser Power | 100W/150W/300W |

| Working Area (W * L) | 1600mm * 3000mm (62.9’’ *118’’) |

| Laser Power | 150W/300W/450W |

|

Working Area (W * L) |

1600mm * 800mm (62.9” * 31.5 ”) |

|

Laser Power |

130W |

Any Question Yo Fabric Laser Cutting & Fabric Laser Engraving?

Let Us Know And Offer Further Advice And Solutions For You!

How To Vision Laser Cut Patterned Textiles

▍Contour Recognition System

Why Would Be Contour Recognition System?

✔ Easily recognize different sizes and shapes of graphics

✔ Achieve Ultra-high-speed recognition

✔ No need for cutting files

✔ Large recognition format

Mimo Contour Recognition System, together with an HD camera is an intelligent option of laser cutting for fabrics with printed patterns. By the printed graphic outlines or color contrast, the contour recognition system can detect the pattern contours without cutting files, achieving a fully automatic and convenient process.

Applications:

Active Wear, Arm Sleeves, Leg Sleeves, Bandanna, Headband, Sublimation Pillow, Rally Pennants, Face Cover, Masks, Rally Pennants, Flags, Posters, Billboards, Fabric Frames, Table Covers, Backdrops, Printed Lace, Appliques, Overlaying, Patches, Adhesive Material, Paper, Leather…

Video: Vision Laser Cutting Skiwear (Sublimation Fabrics)

▍CCD Camera Recognition System

Why would be CCD Mark Positioning?

✔ Accurately locate the cutting item according to the mark points

✔ Precise cutting by the outline

✔ High processing speed together with short software setup time

✔ Compensation of thermal deformation, stretching, shrinkage in materials

✔ Minimal error with digital system control

The CCD camera is equipped beside the laser head to search for the workpiece using registration marks at the start of the cutting procedure. In this way, printed, woven, and embroidered fiducial marks, as well as other high-contrast contours, can be visually scanned so that laser can know where the actual position and dimension of the fabric workpieces are, achieving a precise cutting effect.

Applications:

Embroidery Patch, Twill Numbers & Letter, Label, Applique, Printed Textile…

Video: CCD Camera Laser Cutting Embroidery Patches

▍Template Matching System

Why would be Template Matching System?

✔ Achieve fully automated process, extremely easy and convenient to operate

✔ Achieve high matching speed and high matching success rate

✔ Process a large number of patterns of the same size and shape in a shorter period

When you are cutting small pieces of the same size and shape, especially digital printed or woven labels, it often takes a lot of time and labor costs by processing with the conventional cutting method. MimoWork develops a template matching system that is in a completely automated process, helping to save your time and increase the cutting accuracy for label laser cutting at the same time.

Recommended Vision Laser Cutter for Textiles (Fabrics)

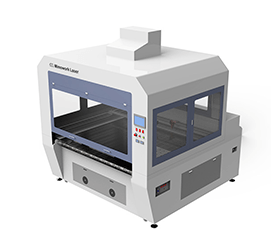

The fully enclosed design is the best laser cutter to consider when investing in a MimoWork Contour Cutter for your dye sublimation fabric production projects. This is not just for cutting sublimation printed fabric with high color-contrast contours, for patterns that are unrecognizable regularly, or for inconspicuous feature point matching...

To meet cutting requirements for large & wide format roll fabric, MimoWork designed the ultra-wide format sublimation laser cutter with CCD Camera to help contour cut the printed fabrics like banners, teardrop flags, signage, exhibition display, etc. 3200mm * 1400mm of working area can carry almost all sizes of fabrics. With the assistance of a CCD...