Laser Cutting Velcro

Laser Cutting Machine for Velcro: Professional and Qualified

Velcro Patch on a Jacket

As a lightweight and durable substitute for fixing something, Velcro has been used in increasing applications, like clothing, bag, footwear, industrial cushion, etc.

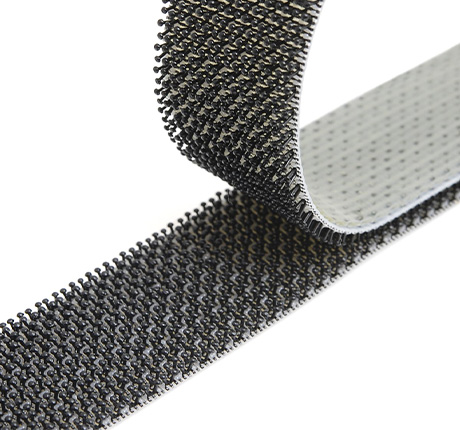

Mostly made of nylon and polyester, Velcro has a hook surface, and the suede surface has a unique material structure.

It has been developed in a variety of shapes as customized requirements grow.

The laser cutter possesses a fine laser beam and swift laser head to realize easily flexible cutting for Velcro. Laser thermal treatment brings sealed and clean edges, getting rid of post-processing for the burr.

What is Velcro?

Velcro: The Wonder of Fasteners

That wonderfully simple invention that has saved countless hours of fumbling with buttons, zippers, and shoelaces.

You know the feeling: you’re in a rush, your hands are full, and all you want is to secure that bag or shoe without a hassle.

Enter Velcro, the magic of hook-and-loop fasteners!

Invented in the 1940s by Swiss engineer George de Mestral, this ingenious material mimics how burrs cling to fur. It’s made up of two components: one side has tiny hooks, and the other has soft loops.

When pressed together, they form a secure bond; a gentle tug is all it takes to release them.

Velcro is everywhere—think shoes, bags, and even space suits! Yes, NASA uses it. Pretty cool, right?

How to Cut Velcro

Traditional Velcro Tape Cutter normally uses a knife tool.

The automatic laser velcro tape cutter can not only cut the velcro into sections but also cut to any shape if needed, even cut small holes on velcro for further processing. Agile and powerful laser head emits the thin laser beam to melt the edge to achieve laser cutting Synthetical Textiles. Sealing edges when cutting.

How to Cut Velcro

Ready to dive into laser cutting Velcro? Here are some tips and tricks to get you started!

1. The Right Type of Velcro & Settings

Not all Velcro is created equal! Look for high-quality, thick Velcro that can withstand the laser cutting process. Experiment with laser power and speed. A slower speed often yields cleaner cuts, while a higher speed can help prevent the material from melting.

2. Test Cut & Ventilation

Always do a few test cuts on scrap pieces before diving into your main project. It’s like a warm-up before a big game! Laser cutting can produce fumes, so ensure you have good ventilation. Your workspace will thank you!

3. Cleaness is Key

After cutting, clean the edges to remove any residue. This not only improves the appearance but also helps with adhesion if you plan to use the Velcro for fastening.

Comparison of CNC Knife and CO2 Laser: Cutting Velcro

Now, if you’re torn between using a CNC knife or a CO2 laser for cutting Velcro, let’s break it down!

CNC Knife: For Velcro Cutting

This method is great for thicker materials and can handle various textures.

It’s like using a precision knife that cuts through like butter.

However, it can be a bit slower and less precise for intricate designs.

CO2 Laser: For Velcro Cutting

On the other hand, this method is fantastic for detail and speed.

It creates clean edges and intricate patterns that make your project pop.

But monitor the settings carefully to prevent burning the Velcro.

In conclusion, if you’re looking for precision and creativity, a CO2 laser is your best bet. But if you’re working with bulkier materials and need sturdiness, a CNC knife might be the way to go. So whether you’re a seasoned pro or just starting your crafting journey, laser-cutting Velcro opens up a world of possibilities. Get inspired, get creative, and let those hooks and loops work their magic!

Benefits From Laser Cut Velcro

Clean and sealed edge

Multi-shapes and sizes

Non distorion & damage

• Sealed and clean edge with heat treatment

• Fine and accurate incision

• High flexibility for material shape and size

• Free of material distortion and damage

• No tool maintenance and replacement

• Automated feeding and cutting

Common Applications of Laser Cut Velcro

Now, let’s talk about laser cutting Velcro. It’s not just for crafting enthusiasts; it’s a game changer in various industries! From fashion to automotive, laser-cut Velcro is popping up in creative ways.

In the fashion world, designers are using it to create unique patterns for jackets and bags. Imagine a stylish coat that’s not only chic but also functional!

In the automotive sector, Velcro is used to secure upholstery and keep things tidy.

And in healthcare, it’s a lifesaver for securing medical devices—comfortably and efficiently.

Application of Laser Cutting on Velcro

Common Applications for Velcro Around Us

• Clothing

• Sports equipment (ski-wear)

• Bag and package

• Automotive sector

• Mechanical engineering

• Medical supplies

One of the best parts?

Laser cutting allows for precise designs and intricate shapes that traditional cutting methods just can’t match.

So, whether you’re a DIY enthusiast or a professional, laser-cut Velcro can add that extra flair to your projects.

Laser Cutter with Extension Table

Embark on a journey to revolutionize fabric-cutting efficiency. The CO2 laser cutter features an extension table, as showcased in this video. Explore the two-head laser cutter with an extension table.

Beyond enhanced efficiency, this industrial fabric laser cutter excels in handling ultra-long fabrics, accommodating patterns longer than the working table itself.

Want to obtain Velcro with various shapes and contours? Traditional processing methods make it difficult to meet the customized requirements, like the knife and punching processes.

No need for mold and tool maintenance, a versatile laser cutter can cut any pattern and shape on Velcro.

FAQ: Laser Cutting Velcro

Q1: Can you Laser Cut Adhesive?

Absolutely!

You can laser cut adhesive, but it’s a bit of a balancing act. The key is to ensure that the adhesive isn’t too thick or it might not cut cleanly. It’s always a good idea to do a test cut first. Just remember: precision is your best friend here!

Q2: Can you Laser Cut Velcro?

Yes, you can!

Laser-cutting Velcro is one of the best ways to achieve precise and intricate designs. Just make sure to adjust your settings to avoid melting the material. With the right setup, you’ll be creating custom shapes in no time!

Q3: What Laser is Best for Laser Cutting Velcro?

The go-to choice for cutting Velcro is typically a CO2 laser.

It’s fantastic for detailed cuts and gives you those clean edges we all love. Just keep an eye on the power and speed settings to get the best results.

Q4: What is Velcro?

Developed by Velcro, the hook and loop have derived more Velcro made from nylon, polyester, blend of nylon and polyester. Velcro is divided into hook surface and suede surface, through the hook surface and suede interlocking each other to form a huge horizontal adhesive tension.

Owning a long service life, about 2,000 to 20,000 times, Velcro has excellent features with lightweight, strong practicability, wide applications, cost-effectively, durable, and repeated washing and use.

Velcro is widely used in clothing, shoes and hats, toys, luggage, and many outdoor sports equipment. In the industrial field, Velcro not only plays a role in connection but also exists as a cushion. It is the first choice for many industrial products because of its low cost and strong stickiness.