Laser Cutting Wood Die Board Factory - 90W Laser Cutter – MimoWork Laser

Laser Cutting Wood Die Board Factory - 90W Laser Cutter – MimoWork Laser Detail:

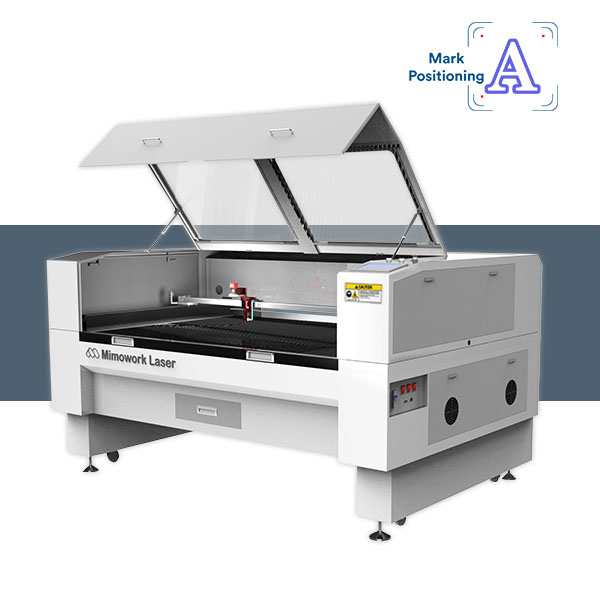

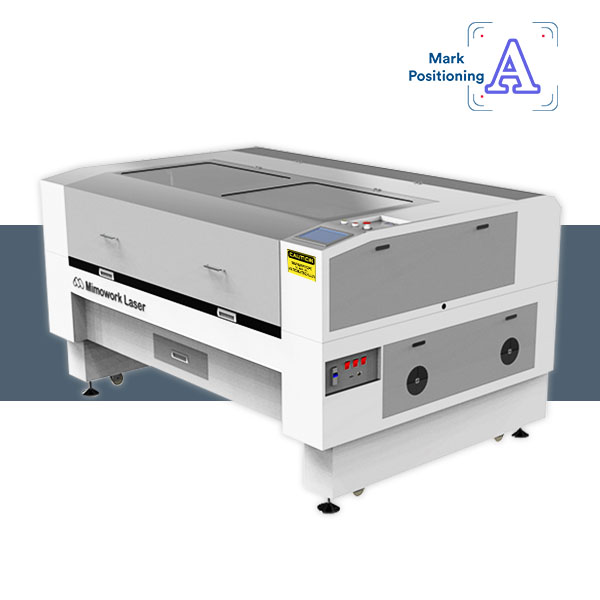

90W Laser Cutter – Lets your imagination run wild with it

Technical Data

| Working Area (W *L) |

1000mm * 600mm (39.3” * 23.6 ”) 1300mm * 900mm(51.2” * 35.4 ”) 1600mm * 1000mm(62.9” * 39.3 ”) <Customized Table Sizes Available> |

| Software | Offline Software |

| Laser Power | 90W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* More sizes of laser working table are customizable

* Higher Power Laser Tube are customizable

▶ Customizable Working Table Available: The 90W Laser Cutter is suitable to cut and engrave on solid materials such as acrylic and wood. Honey comb working table and knife strip cutting table can carry the materials and help to reach best the cutting effect without dust and fume that can be sucked into and purified.

<a href="https://www.mimowork.com/working-table/" title=">> Discover laser cutting tables” target=”_blank”>

>> Discover laser cutting tables

<a href="https://www.mimowork.com/fume-extractor/" title=">> Discover laser fume extractor” target=”_blank”>

>> Discover laser fume extractor

Highlights of Modern Engineering

90W CO2 Laser Cutter

Auto Focus

It is mainly used for metal cutting. You may need to set a certain focus distance in the software when the cutting material is not flat or with different thickness. Then the laser head will automatically go up and down, keeping the same height & focus distance to match with what you set inside the software to achieve a consistently high cutting quality.

Servo Motors

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops. Servo motors ensure higher speed and higher precision of the laser cutting and engraving.

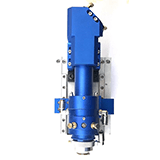

Ball & Screw

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The ball assembly acts as the nut while the threaded shaft is the screw. In contrast to conventional lead screws, ball screws tend to be rather bulky, due to the need to have a mechanism to re-circulate the balls. The ball screw ensures high speed and high precision laser cutting.

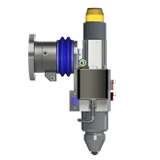

Mixed Laser Head

A mixed laser head, also known as a metal non-metallic laser cutting head, is a very important part of the metal & non-metal combined laser cutting machine. With this professional laser head, you can cut both metal and non-metal materials. There is a Z-Axis transmission part of the laser head that moves up and down to track the focus position. Its double drawer structure enables you to put two different focus lenses to cut the materials of different thicknesses without adjustment of focus distance or beam alignment. It increases cutting flexibility and makes the operation very easy. You can use different assist gas for different cutting jobs.

Want to further increase its Potential with upgrades?

Video of Laser Cutting Christmas Ornaments (Wood)

Turning Wood into Festive Christmas Ornaments

Materials Like Acrylic, Wood, Paper, Plastic, Glass, MDF, Plywood, Laminates, Leather, and other Non-metal Materials are commonly processed by the 90W Laser Cutter.

Products like Signs(signage), Crafts, Jewelry, Key chains, Arts, Awards, Trophies, Gifts and etc are often produced by the 90W Laser Cutter.

View more materials

View more applications

CO2 Laser Guides & Tutorials

Related Videos

Tutorial: How to find the focus of the laser lens?

How To Clean And Install Laser Focus Lens

We Provide Excellent Aftersales Service for Our Customers

Don’t settle for anything less than exceptional results

Invest in the Best

Product detail pictures:

Related Product Guide:

Our concentrate on is always to consolidate and enhance the excellent and service of present solutions, in the meantime regularly develop new products to meet distinctive customers' demands for Laser Cutting Wood Die Board Factory - 90W Laser Cutter – MimoWork Laser , The product will supply to all over the world, such as: Bandung , Algeria , Iraq , Due to good quality and reasonable prices, our items have been exported to more than 10 countries and regions. We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.