Laser Cutting X-Pac Fabric

Laser cutting technology has revolutionized the way we process technical textiles, offering precision and efficiency that traditional cutting methods cannot match. X-Pac fabric, known for its strength and versatility, is a popular choice in outdoor gear and other demanding applications. In this article, we will explore the composition of X-Pac fabric, address safety concerns related to laser cutting, and discuss the advantages and wide applications of using laser technology on X-Pac and similar materials.

What is X-Pac Fabric?

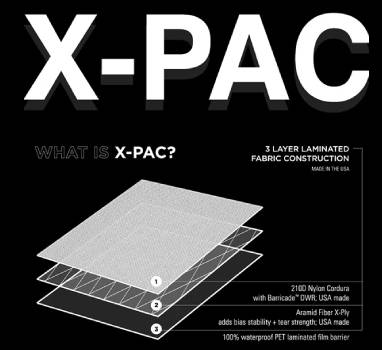

X-Pac fabric is a high-performance laminate material that combines multiple layers to achieve exceptional durability, waterproofing, and tear resistance. Its construction typically includes a nylon or polyester outer layer, a polyester mesh known as X-PLY for stability, and a waterproof membrane.

Some X-Pac variants feature a Durable Water-repellent (DWR) coating for enhanced water resistance, which may produce toxic fumes during laser cutting. For these, if you want to laser cut, we suggest you should equip a well-performed fume extractor coming with the laser machine, that can effectively purify the waste. For others, some DWR-0 (fluorocarbon-free) variants, are safe to be laser cut. The applications of laser cutting X-Pac have been used in many industries like outdoor gear, functional clothing, etc.

Material Structure:

X-Pac is constructed from a combination of layers including nylon or polyester, a polyester mesh (X-PLY®), and a waterproof membrane.

Variants:

X3-Pac Fabric: Three layers of construction. One layer of polyester backing, one layer of X‑PLY® fiber reinforcement, and a water-proof face fabric.

X4-Pac Fabric: Four layers of construction. It has one more layer of taffeta backing than X3-Pac.

Other Variants have different deniers like 210D, 420D, and various proportions of ingredients.

Applications:

X-Pac is used in applications requiring high strength, water resistance, and lightweight, like backpacks, tactile gear, bulletproof vests, sailcloths, automotive parts, and more.

Can You Laser Cut X-Pac Fabric?

Laser cutting is a powerful method for cutting technical textiles including X-Pac fabric, Cordura, Kevlar, and Dyneema. The fabric laser cutter produces a thin but powerful laser beam, to cut through the materials. The cutting is precise and saves materials. Also, the non-contact and precise laser cutting offers a higher cutting effect with clean edges, and flat and intact pieces. That is difficult to achieve with traditional tools.

While laser cutting is generally feasible for X-Pac, safety considerations must be taken into account. Besides these safe ingredients like polyester and nylon we have known, there are so many commercially available chemicals can be blended into the materials, so we suggest you should consult a professional laser expert for specific advice. In general, we recommend sending us your material samples for a laser test. We will test the feasibility of laser cutting your material, and find the suitable laser machine configurations and optimal laser cutting parameters.

Who Are We?

MimoWork Laser, an experienced laser cutting machine manufacturer in China, have a professional laser technology team to solve your problems from laser machine selection to operation and maintenance. We have been researching and developing various laser machines for different materials and applications. Check out our laser cutting machines list to get an overview.

Video Demo: Perfect Result of Laser Cutting X-Pac Fabric!

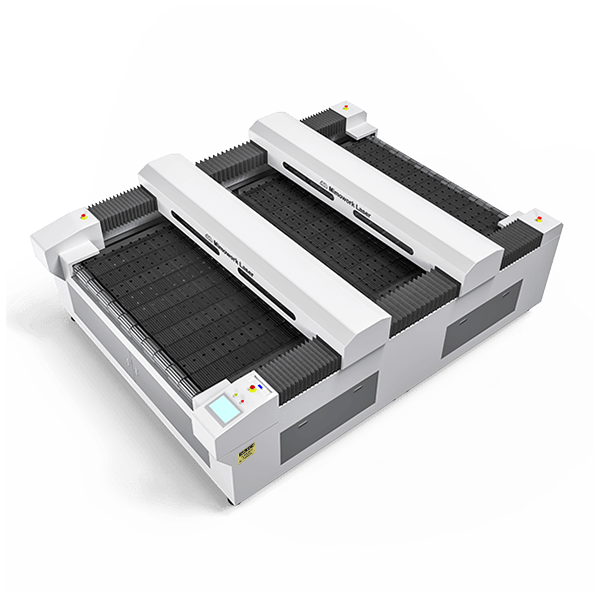

Interested in the laser machine in the video, check out this page about the Industrial Fabric Laser Cutting Machine 160L, you will find more detailed information. If you want to discuss your requirements and a suitable laser machine with our laser expert, please email us directly at info@mimowork.com.

Benefits from Laser Cutting X-Pac Fabric

✔ Precision and Details: The laser beam is pretty fine and sharp, leaving a thin cut kerf on the material. Plus with the digital control system, you can use the laser to create various styles and different graphics of cutting design.

✔ Clean Edges: Laser cutting can seal the fabric edge during cutting, and due to its sharp and fast cutting, it will bring a clean and smooth cutting edge.

✔ Fast Cutting: Laser cutting X-Pac fabric is faster than traditional knife cutting. And there are multiple laser heads are optional, you can choose suitable configurations according to your production requirements.

✔ Minimal Material Waste: The precision of laser cutting reduces X-Pac waste, optimizing usage and lowering costs. Auto-nesting software coming with a laser machine can help you with pattern layout, saving materials and time costs.

✔ Enhanced Durability: There is no damage to X-Pac fabric due to the laser's non-contact cutting, which contributes to the longevity and durability of the final product.

✔ Automation and Scalability: Auto feeding, conveying, and cutting boost production efficiency, and the high automation saves labor costs. Suitable for both small and large-scale production.

A Few Highlights of Laser Cutting Machine >

2/4/6 laser heads are optional according to your production efficiency and yield. The design significantly increases the cutting efficiency. But more does not mean better, after talking with our clients, we will based on the production demand, find a balance between the number of laser heads and the load. Consult us >

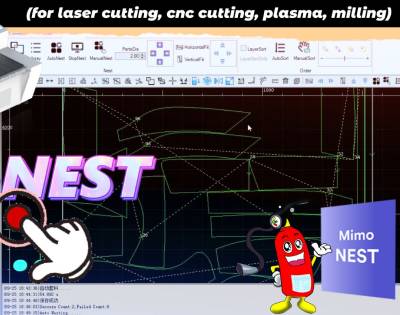

MimoNEST, the laser cutting nesting software helps fabricators to minimize the cost of materials and improves the utilization rate of materials by using advanced algorithms that analyze the variance of parts. In simple terms, it can place the laser cutting files on the material perfectly.

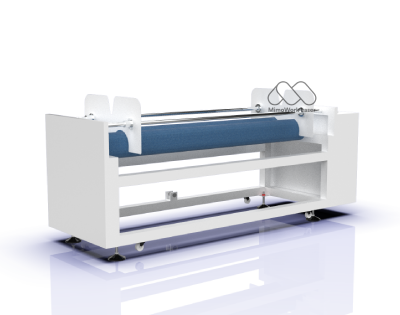

For roll materials, the combination of auto-feeder and conveyor table is an absolute advantage. It can automatically feed the material onto the working table, smoothing the whole workflow. Saving time and guaranteeing the material flat.

To absorb and purify the waste fume and smoke from laser cutting. Some composite materials have chemical content, that can release the pungent odor, in this case, you need a great exhaust system.

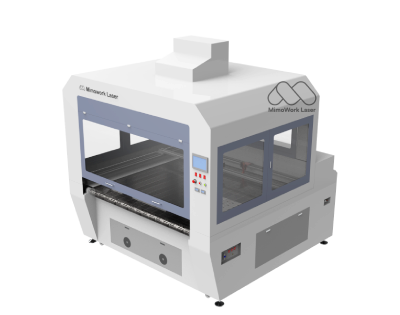

The fully enclosed structure of laser cutting machine is designed for some clients with higher requirements for safety. It prevent the operator from directly contact with the working area. We specially installed the acrylic window so that you can monitor the cutting condition inside.

Recommended Fabric Laser Cutter for X-Pac

• Laser Power: 100W / 150W / 300W

• Working Area: 1600mm * 1000mm

Flatbed Laser Cutter 160

Fitting the regular clothing and garment sizes, the fabric laser cutter machine has a working table of 1600mm * 1000mm. The soft roll fabric is pretty suitable for laser cutting. Except that, leather, film, felt, denim and other pieces can all be laser cut thanks to the optional working table. The steady structure is the base of production...

• Laser Power: 100W/150W/300W

• Working Area: 1800mm * 1000mm

Flatbed Laser Cutter 180

To meet more varieties of cutting requirements for fabric in different sizes, MimoWork widens the laser cutting machine to 1800mm * 1000mm. Combined with the conveyor table, roll fabric and leather can be allowed to convey and laser cutting for fashion and textiles without interruption. In addition, multi-laser heads are accessible to enhance the throughput and efficiency...

• Laser Power: 150W / 300W / 450W

• Working Area: 1600mm * 3000mm

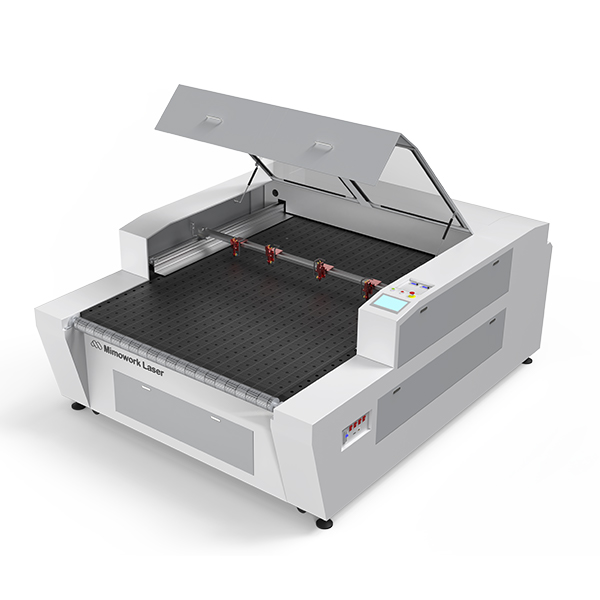

Flatbed Laser Cutter 160L

The MimoWork Flatbed Laser Cutter 160L, characterized by the large-format working table and higher power, is widely adopted for cutting industrial fabric and functional clothing. Rack & pinion transmission and servo motor-driven devices provide steady and efficient conveying and cutting. CO2 glass laser tube and CO2 RF metal laser tube are optional...

• Laser Power: 150W / 300W / 450W

• Working Area: 1500mm * 10000mm

10 Meters Industrial Laser Cutter

The Large Format Laser Cutting Machine is designed for ultra-long fabrics and textiles. With a 10-meters long and 1.5-meters wide working table, the large format laser cutter is suitable for most fabric sheets and rolls like tents, parachutes, kitesurfing, aviation carpets, advertising pelmet and signage, sailing cloth and etc. Equipped with a strong machine case and a powerful servo motor...

Select One Laser Cutting Machine Suitable for Your Production

MimoWork is here to offer professional advice and suitable laser solutions !

Examples of Products Made with Laser-Cut X Pac

Outdoor Gear

X-Pac is ideal for backpacks, tents, and accessories, offering durability and water resistance.

Protective Equipment

Used in protective clothing and gear, along with materials like Cordura and Kevlar.

Aerospace & Automotive Parts

X-Pac can be used in seat covers and upholstery, providing durability and resistance to wear and tear while maintaining a sleek appearance.

Marine and Sailing Products

X-Pac's ability to withstand harsh marine conditions while maintaining flexibility and strength makes it an attractive choice for sailors looking to enhance their sailing experience.

Related Materials to X-Pac can be Laser Cut

Cordura is a durable and abrasion-resistant fabric, used in rugged gear. We have tested laser cutting Cordura and the cutting effect is great, for more details please check out the following video.

Kevlar®

High tensile strength and thermal stability for protective and industrial applications.

What Materials Are You Gonna Laser Cut? Talk with Our Expert!

Our Suggestions about Laser Cutting X-Pac

1. Confirm the composition of the material you are gonna cut, better choose DWE-0, Chloride-free.

2. If you are not sure of the materials composition, consult your material supplier and laser machine supplier. It’s best to open your fume extractor coming with the laser machine.

3. Now laser cutting technology is more mature and safer, so don’t resist laser cutting for composites. Like nylon, polyester, Cordura, ripstop nylon, and Kevlar, have been tested using laser machine, it’s feasible and with great effect. The point has been common sense in clothing, composites, and outdoor gear fields. If you are not sure, please don’t hesitate to inquire with a laser expert, to consult whether your material is laseable and whether it’s safe. We know the materials are constantly being updated and improved, and the laser cutting too, it is moving forward to greater safety and efficiency.