Laser Die Board Cutting Machine Suppliers - Laser Cutter for Cloth – MimoWork Laser

Laser Die Board Cutting Machine Suppliers - Laser Cutter for Cloth – MimoWork Laser Detail:

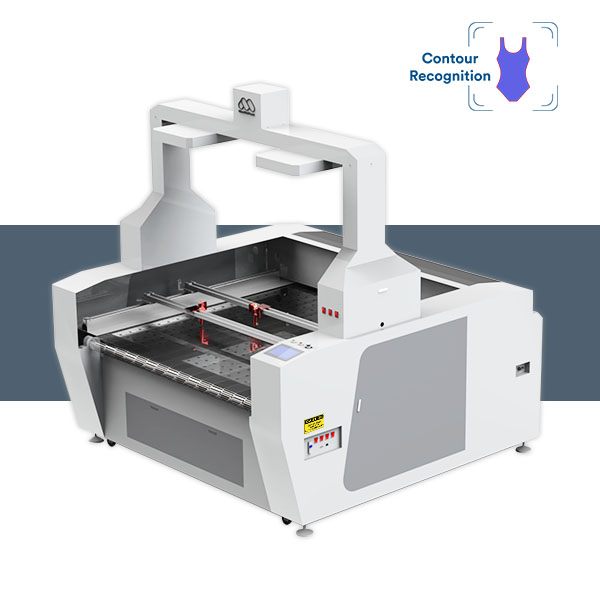

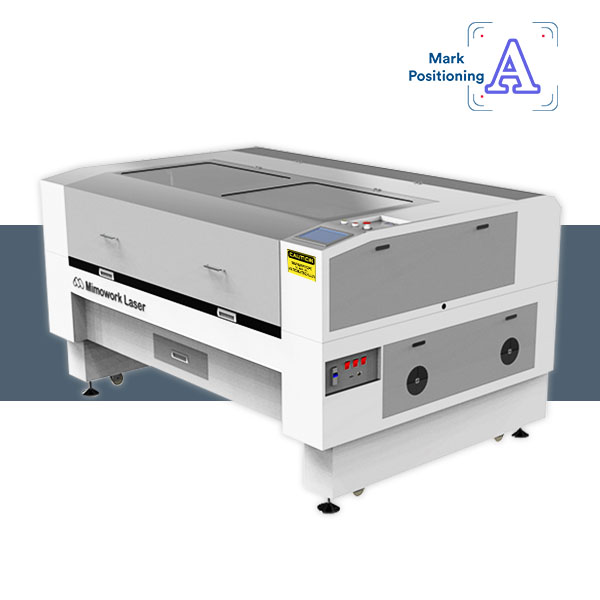

▶ Automatic laser cloth cutting machine

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Collecting Area (W * L) | 1600mm * 500mm (62.9” * 19.7”) |

| Software | Offline Software |

| Laser Power | 100W / 150W / 300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive / Servo Motor Drive |

| Working Table | Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Multiple Laser Heads option available

Mechanical Structure

Safe & Stable Structure

- Safe Circuit

Safe Circuit is for the safety of people in the machine environment. Electronic safety circuits implement interlock safety systems. Electronics give far greater flexibility in the arrangement of guards and the complexity of safety procedures than mechanical solutions.

- Extension Table

The extension table is convenient for collecting fabric being cut, especially for some small fabric pieces like plush toys. After cutting, these fabrics can be conveyed to the collection area, eliminating manual collecting.

- Signal Light

The signal light is designed to signal to people using the machine whether the laser cutter is in use. When the signal light turns green, it informs people that the laser cutting machine is on, all cutting work is done, and the machine is ready for people to use. If the light signal is red, it means everyone should stop and not turn on the laser cutter.

- Emergency Button

An emergency stop, also known as a kill switch (E-stop), is a safety mechanism used to shut down a machine in an emergency when it cannot be shut down in the usual way. The emergency stop ensures the safety of operators during the production process.

High-automation

- Vacuum Suction System

Vacuum tables are commonly used in CNC machining as an effective way to hold material onto the work surface while the rotary attachment cuts. It uses the air from the exhaust fan to hold thin sheet stock flat.

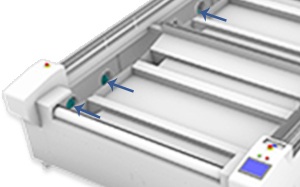

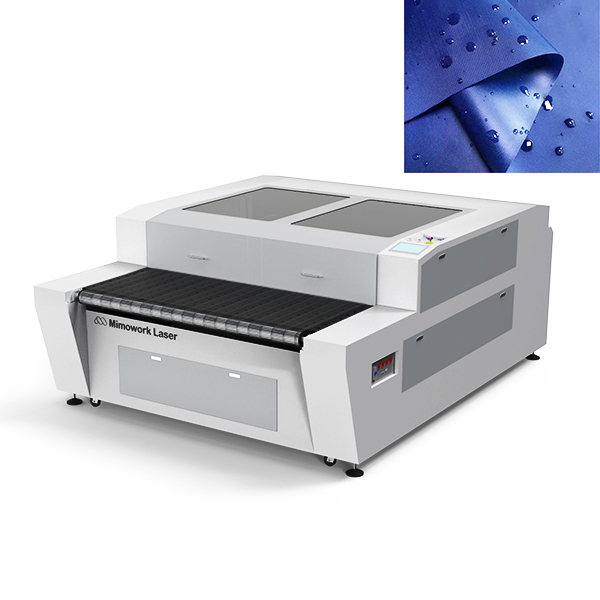

- Conveyor System

The Conveyer System is the ideal solution for series and mass production. The combination of the Conveyer table and the auto feeder provides the easiest production process for cut coiled materials. It transports the material from the roll to the machining process on the laser system.

▶ Extend more possibilities on laser cutting fashion

Upgrade Options you can choose

Two Laser Heads – Option

Most simply and economically to speed up your production efficiency is to mount multiple laser heads on the same gantry and cut the same pattern simultaneously. This doesn’t take extra space or labor. If you need to cut a lot of identical patterns, this would be a perfect choice for you.

Nesting Software – Option

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further human intervention.

Auto Feeding System

The Auto Feeder combined with the Conveyor Table is the ideal solution for series and mass production. It transports the flexible material (fabric most of the time) from the roll to the cutting process on the laser system. With stress-free material feeding, there is no material distortion while contactless cutting with laser ensures outstanding results.

Marker Pen Module

You can use the marker pen to make the marks on the cutting pieces, enabling the workers to sew easily. You can also use it to make special marks such as the serial number of the product, the size of the product, the manufacture date of the product, etc.

Fume Extractor – Option

Melting the surface of the material to achieve the perfect cutting result, CO2 laser processing may generate lingering gases, pungent odor, and airborne residues when you are cutting synthetic chemical materials and the CNC router can’t deliver the same precision that laser does. MimoWork Laser Filtration System can help one puzzle out the bothersome dust and fumes while minimizing disruption to production.

(laser cut legging, laser cut dress, laser cut clothing…)

Fabric Samples

Pictures Browse

Find more videos about our laser cutters at our Video Gallery

Video Display

Denim Fabric Laser Cutting

✦ Efficiency: Auto feeding & cutting & collecting

✦ Quality: Clean edge without fabric distortion

✦ Flexibility: Various shapes and patterns can be laser cut

Related Fabric Laser Cutters

Laser Fabric Cutter

• Laser Power: 100W/150W/300W

• Working Area (W *L): 1600mm * 1000mm

Textile laser cutting machine (fabric)

• Laser Power: 100W/150W/300W

• Working Area (W *L): 1800mm * 1000mm

Industrial Laser Cutter for Fabric

• Laser Power: 150W/300W/500W

• Working Area (W *L): 1600mm * 3000mm

Let the garment laser cutting machine extend your production

MimoWork is your trusted partner!

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of regard the market, regard the custom, regard the science as well as the theory of quality the basic, believe in the 1st and management the advanced for Laser Die Board Cutting Machine Suppliers - Laser Cutter for Cloth – MimoWork Laser , The product will supply to all over the world, such as: Chile , Albania , Lisbon , Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we are working hard to give you the wholehearted service and willing to give you the most competitive price in the market

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.