Denim Laser Engraving

(laser marking, laser etching, laser cutting)

Denim, as a vintage and vital fabric, is always ideal for creating detailed, exquisite, timeless embellishments for our daily clothing and accessories.

However, traditional washing processes like chemical treatment on denim have environmental or health implications, and care must be taken in handling and disposal.

Differently from that, laser engraving denim and laser marking denim are more environment-friendly and sustainable methods.

Why say that? What benefits can you get from laser engraving denim? Read on to find more.

Laser Processing for Denim Fabric

The laser can burn the surface textile off the denim fabric to expose the original color of the cloth.

Denim with the effect of rendering can also be matched with different fabrics, such as fleece, imitation leather, corduroy, thick felt fabric, and so on.

1. Denim Laser Engraving & Etching

Denim laser engraving and etching are cutting-edge techniques that allow for the creation of detailed designs and patterns on denim fabric.

Utilizing high-powered lasers, these processes remove the top layer of dye, resulting in stunning contrasts that highlight intricate artwork, logos, or decorative elements.

Engraving offers precise control over depth and detail, making it possible to achieve a range of effects from subtle texturing to bold imagery.

The process is quick and efficient, enabling mass customization while maintaining high-quality results.

Additionally, laser engraving is eco-friendly, as it eliminates the need for harsh chemicals and minimizes material waste.

Video Show: [Laser Engraved Denim Fashion]

Laser Engraved Jeans in 2023 - Embrace the '90s Trend!

The '90s fashion is back, and it's time to give your jeans a stylish twist with denim laser engraving.

Join the trendsetters like Levi’s and Wrangler in modernizing your jeans.

You don't need to be a big brand to get started–just toss your old jeans into a jeans laser engraver!

With a denim jeans laser engraving machine, mixed with some stylish and customized pattern design, dazzling it’s what it will be.

2. Denim Laser Marking

Laser marking denim is a process that uses focused laser beams to create permanent markings or designs on the fabric's surface without removing material.

This technique allows for the application of logos, text, and intricate patterns with high precision.

Laser marking is known for its speed and efficiency, making it ideal for both large-scale production and custom projects.

Laser marking on denim does not penetrate deeply into the material.

Instead, it changes the color or shade of the fabric, creating a more subtle design that is often more resistant to wear and washing.

3. Denim Laser Cutting

The versatility of laser cutting denim and jeans enables manufacturers to easily produce various styles, from trendy distressed looks to tailored fits, while maintaining efficiency in production.

Additionally, the ability to automate the process enhances productivity and reduces labor costs.

With its eco-friendly advantages, such as reduced waste and no need for harmful chemicals, laser cutting aligns with the growing demand for sustainable fashion practices.

As a result, laser cutting has become an essential tool for denim and jeans production, empowering brands to innovate and meet consumer demands for quality and customization.

Video Show: [Laser Cutting Denim]

Discover What Is Laser Engraving Denim

◼ Video Glance - Denim Laser Marking

In this video

We used the Galvo Laser Engraver to work on the laser engraving denim.

With the advanced Galvo laser system and conveyor table, the whole denim laser marking process is fast and automatic.

The agile laser beam is delivered by the precise mirrors and worked on the denim fabric surface, creating laser etched effect with exquisite patterns.

Key Facts

✦ Ultra-speed and fine laser marking

✦ Auto-feeding and marking with conveyor system

✦ Upgraded extensile working table for different material formats

◼ Brief Understanding of Denim Laser Engraving

As an enduring classic, denim cannot be considered a trend, it will never go in and out of fashion.

Denim elements have always been the classic design theme of the clothing industry, deeply loved by designers, denim clothing is the only popular clothing category in addition to the suit.

For jeans-wearing, tearing, aging, dying, perforating and other alternative decoration forms are the signs of punk, hippie movement.

With unique cultural connotations, denim gradually became cross-century popular, and gradually developed into a worldwide culture.

The MimoWork Laser Engraving Machine offers tailored laser solutions for denim fabric manufacturers.

With capabilities for laser marking, engraving, perforating, and cutting, it enhances the production of denim jackets, jeans, bags, pants, and other apparel and accessories.

This versatile machine plays a crucial role in the denim fashion industry, enabling efficient and flexible processing that drives innovation and style forward.

◼ Benefits from Laser Engraving on Denim

Different etching depths (3D effect)

Continuous pattern marking

Perforating with multi-sizes

✔ Precision and Detail

Laser engraving allows for intricate designs and precise detailing, enhancing the visual appeal of denim products.

✔ Customization

It offers endless customization options, enabling brands to create unique designs tailored to their customers' preferences.

✔ Durability

Laser-engraved designs are permanent and resistant to fading, ensuring long-lasting quality on denim items.

✔ Eco-Friendly

Unlike traditional methods that may use chemicals or dyes, laser engraving is a cleaner process, reducing environmental impact.

✔ High Efficiency

Laser engraving is quick and can be easily integrated into production lines, increasing overall efficiency.

✔ Minimal Material Waste

The process is precise, resulting in less material waste compared to cutting or other engraving methods.

✔ Softening Effect

Laser engraving can soften the fabric in engraved areas, providing a comfortable feel and enhancing the garment's overall aesthetic.

✔ Variety of Effects

Different laser settings can produce a range of effects, from subtle etching to deep engraving, allowing for creative design flexibility.

◼ Typical Applications of Laser Engraving Denim

• Apparel

- jeans

- jacket

- shoes

- pants

- skirt

• Accessories

- bags

- home textiles

- toy fabrics

- book cover

- patch

Recommended Laser Machine For Denim

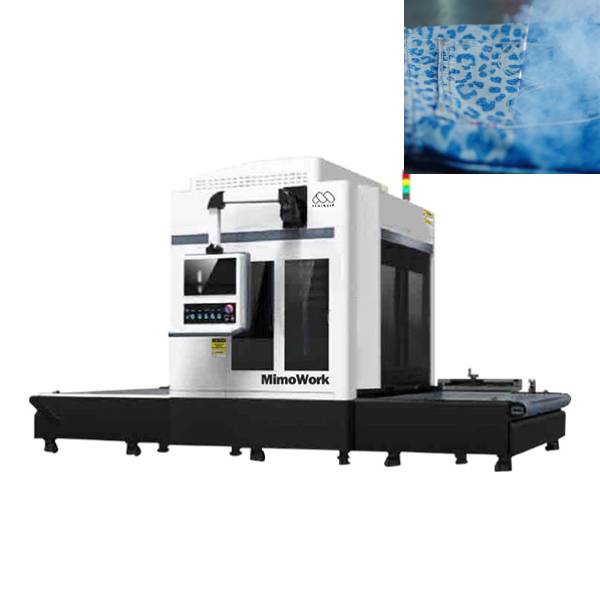

◼ Deinm Laser Engraving & Marking Machine

• Laser Power: 250W/500W

• Working Area: 800mm * 800mm (31.4” * 31.4”)

• Laser Tube: Coherent CO2 RF Metal Laser Tube

• Laser Working Table: Honey Comb Working Table

• Max Marking Speed: 10,000mm/s

To meet faster denim laser marking requirements, MimoWork developed the GALVO Denim Laser Engraving Machine.

With a working area of 800mm * 800mm, the Galvo laser engraver can handles most pattern engraving and marking on denim pants, jackets, denim bag, or other accessories.

• Laser Power: 350W

• Working Area: 1600mm * Infinity (62.9" * Infinity)

• Laser Tube: CO2 RF Metal Laser Tube

• Laser Working Table: Conveyor Working Table

• Max Marking Speed: 10,000mm/s

The large format laser engraver is R&D for large size materials laser engraving & laser marking. With the conveyor system, the galvo laser engraver can engrave and mark on roll fabrics (textiles).

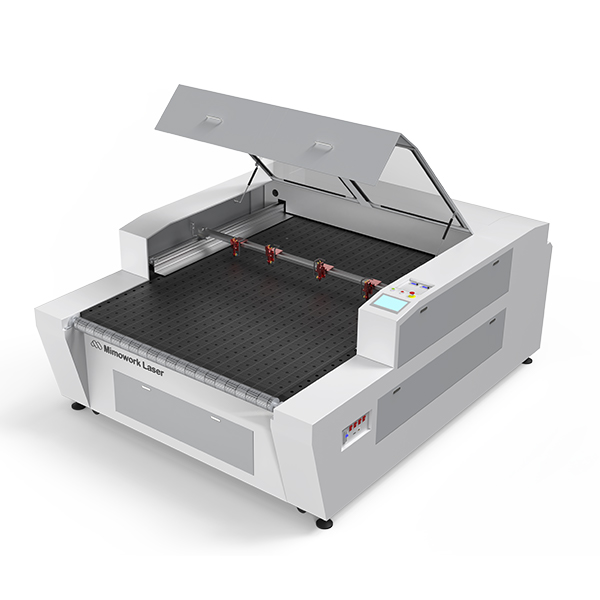

◼ Denim Laser Cutting Machine

• Laser Power: 100W/150W/300W

• Working Area: 1600mm * 1000mm

• Laser Working Table: Conveyor Working Table

• Max Cutting Speed: 400mm/s

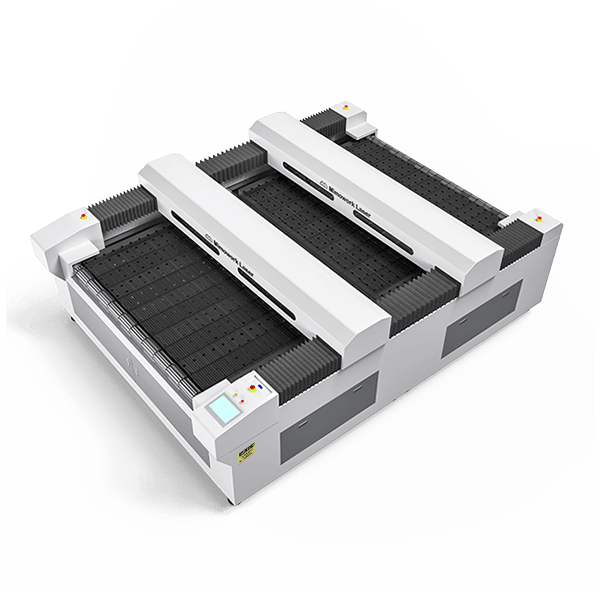

• Laser Power: 100W/150W/300W

• Working Area: 1800mm * 1000mm

• Collection Area: 1800mm * 500mm

• Max Cutting Speed: 400mm/s

• Laser Power: 150W/300W/450W

• Working Area: 1600mm * 3000mm

• Laser Working Table: Conveyor Working Table

• Max Cutting Speed: 600mm/s

What Are You Gonna Make with Denim Laser Machine?

Trend of Laser Etching Denim

Before we explore the environmentally friendly aspects of laser etching denim, it’s important to highlight the capabilities of the Galvo Laser Marking Machine.

This innovative technology allows designers to showcase incredibly fine details in their creations.

Compared to traditional plotter laser cutters, the Galvo machine can achieve complex "bleached" designs on jeans in just minutes.

By significantly reducing manual labor in denim pattern printing, this laser system empowers manufacturers to easily offer customized jeans and denim jackets.

The concepts of sustainable and regenerative design are gaining traction in the fashion industry, becoming an irreversible trend.

This shift is particularly evident in the transformation of denim fabric.

At the core of this transformation is a commitment to environmental protection, the use of natural materials, and creative recycling, all while preserving design integrity.

Techniques employed by designers and manufacturers, such as embroidery and printing, not only align with current fashion trends but also embrace the principles of green fashion.