Laser Mould Cleaning

Laser mold cleaning is an advanced technique used to remove contaminants from industrial molds, particularly in the manufacturing of plastic and rubber components. It enhances manufacturing efficiency while ensuring high-quality results. Its precision and eco-friendliness make it a preferred choice in modern industrial applications.

How Laser Mould Cleaning Works

Efficiency, Cost-Effective and Quality Maintenance

Various Mould Used by Various Industries

High-powered lasers emit focused beams of light that can precisely target and remove contaminants without damaging the underlying surface. Common laser types used include CO2 and fiber lasers.

Process Steps for Laser Surface Cleaning

The mold is inspected and any loose debris is removed. The laser is directed at the mold surface.

The energy from the laser causes the contaminants (like resin, grease, or rust) to either vaporize or be blown away by the force of the laser beam. Operators monitor the cleaning process to ensure effectiveness and adjust parameters as needed.

Advantages for Laser Surface Cleaning:

Unlike traditional cleaning methods (like sandblasting), laser cleaning does not wear down the mold surface. Lasers can clean intricate designs without affecting the mold geometry.

Laser Mold Cleaning reduces the need for harsh chemicals and solvents.

Benefits of Laser Mold Cleaning

Laser Mold Cleaning Offers Several Benefits that Make It a Preferred Choice

Laser Mould Cleaning

Laser mold cleaning is a modern solution that combines efficiency, precision, and environmental benefits, making it a valuable choice for industries focused on quality and sustainability.

Non-Damaging, Precision and Environmentally Friendly

The non-abrasive nature of laser cleaning prevents wear and tear on the mold surfaces.

Maintaining their original shape and functionality.

Lasers can precisely focus on specific areas, making them ideal for intricate mold designs and hard-to-reach spots. This method minimizes the need for harsh chemicals and solvents, promoting a safer and more sustainable cleaning process.

Cost-Effective, Versatility and Safety

By extending the lifespan of molds and reducing the need for manual labor and cleaning supplies, laser cleaning can lead to significant cost savings.

Effective on various contaminants, including grease, oil, rust, and plastic residues, making it suitable for different industries. As it requires less manual handling of heavy cleaning equipment and chemicals, it enhances workplace safety.

Mould Laser Cleaning: Applications

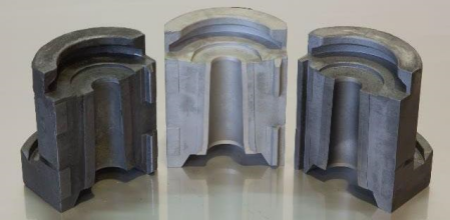

Rubber Mould

Laser mould cleaning for rubber moulds is an advanced and efficient method designed specifically for the unique properties of rubber materials.

This process not only enhances the longevity of the moulds but also improves product quality by preventing imperfections in the final rubber products.

Ideal for industries relying on precision and high-quality standards, laser mould cleaning is a sustainable solution that reduces downtime and enhances operational efficiency.

Plastic Mould

Laser mould cleaning for plastic moulds remove dirt, residues, and other contaminants from mould surfaces without causing any physical damage.

Unlike traditional cleaning techniques, which can lead to scratches or wear, laser cleaning is precise and non-abrasive, preserving the integrity of the mould.

Ideal for manufacturers aiming for superior quality and sustainability, this innovative approach enhances the lifespan of plastic moulds while improving overall productivity.

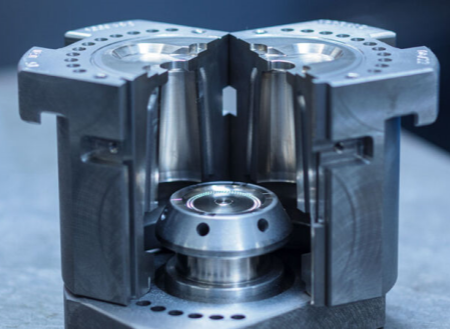

Laser Mould Cleaning: Injection Mold

Injection Mold

Laser mold cleaning for injection molds offers specialized benefits that are crucial for maintaining the precision and performance of these complex tools.

Laser cleaning ensures that the fine tolerances essential for injection molding are preserved, preventing defects in the final products.

By enhancing the cleanliness of the molds, this process promotes better heat transfer and consistent material flow, resulting in improved cycle times and higher-quality finishes.

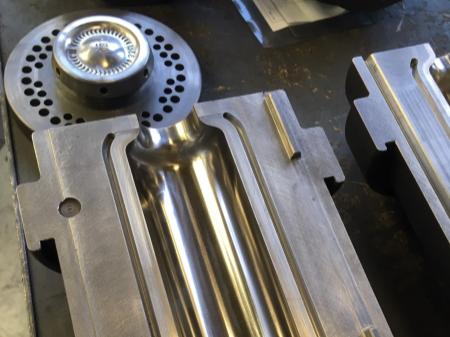

Composites Mold

Laser mould cleaning for composites moulds provides unique advantages tailored to the complexities of composite materials.

This innovative cleaning method effectively removes cured resin, gel coats, and other stubborn residues without damaging the delicate surface of the mould.

Ideal for manufacturers in the aerospace and automotive industries, this method enhances efficiency and ensures high-performance outcomes in composite production.

Laser Mould Cleaning: Composites Mold

Want to Know about How Laser Mould Cleaning Works?

We Can Help!

Do Laser Cleaning Machines Really Work?

What is Laser Cleaning & How it Works?

Do laser cleaning machines really work? Absolutely!

These advanced devices are highly effective for mass cleaning moulds across various industries.

Laser cleaners utilize focused beams of light to precisely remove contaminants, residues, and build-up without damaging the mould surfaces.

In large-scale operations, the efficiency of laser cleaning translates to reduced downtime and lower labor costs, as multiple moulds can be cleaned simultaneously with minimal supervision. Furthermore, laser cleaning is environmentally friendly, reducing the need for harsh chemicals and waste disposal.

For Laser Mould Cleaning?

Pulsed Laser Cleaner (100W, 200W, 300W, 400W)

For manufacturers looking to maintain high standards of cleanliness and quality while optimizing their production lines, laser cleaning machines offer a powerful solution that enhances both performance and sustainability.

Laser Power: 100-500W

Pulse Length Modulation: 10-350ns

Fiber Cable Length: 3-10m

Wavelength: 1064nm

Laser Source: Pulsed Fiber Laser