Laser Weld Cleaning

Laser Weld Cleaning is a Technique used to Remove Contaminants, Oxides, and Other Unwanted Material from the Surface of a Weld Before & After the Welding Process is Complete. This Cleaning is an Important Step in Many Industrial and Manufacturing Applications to Ensure the Integrity and Appearance of the Welded Joint.

Laser Cleaning for Metal

During the welding process, various impurities and byproducts can become deposited on the weld surface, such as slag, spatter, and discoloration.

Left uncleaned, these can negatively impact the weld's strength, corrosion resistance, and visual aesthetics.

Laser weld cleaning uses a high-energy laser beam to selectively vaporize and remove these undesirable surface deposits without damaging the underlying metal.

Advantages of Laser Weld Cleaning

1. Precision - The laser can be precisely targeted to clean only the weld area without affecting the surrounding material.

2. Speed - Laser cleaning is a rapid, automated process that can clean welds much faster than manual techniques.

3. Consistency - Laser cleaning produces a uniform, repeatable result, ensuring all welds are cleaned to the same high standard.

4. No Consumables - Laser cleaning requires no abrasives or chemicals, reducing operating costs and waste.

Applications: Laser Weld Cleaning

High-Strength Low-Alloy (HSLA) Steel Plates Laser Weld Cleaning

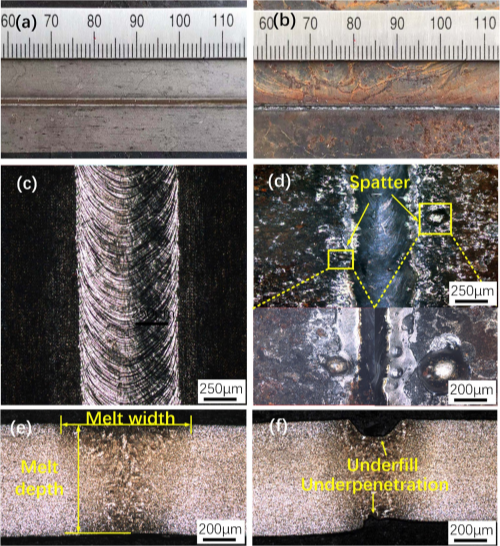

Weld Appearance of Treated by Laser Cleaning (a, c, e) and Untreated by Laser Cleaning (b, d, f)

The proper laser cleaning process parameters can remove the rusting and grease from the workpiece surface.

Higher penetration was observed in specimens that were cleaned compared with those not cleaned.

The laser cleaning pre-treatment effectively helps avoid the occurrence of pores and cracks in the weld and improves the forming quality of the weld.

Laser Weld Cleaning pre-treatment reduces many defects such as pores and cracks inside the weld, thus improving the tensile properties of the weld.

The average tensile strength of the sample with laser cleaning pre-treatment is 510 MPa, which is 30% higher than that without laser cleaning pre-treatment.

The elongation of the laser-cleaned weld joint is 36% which is 3 times that of the uncleaned weld joint (12%).

Commercial Aluminum Alloy 5A06 Laser Weld Cleaning

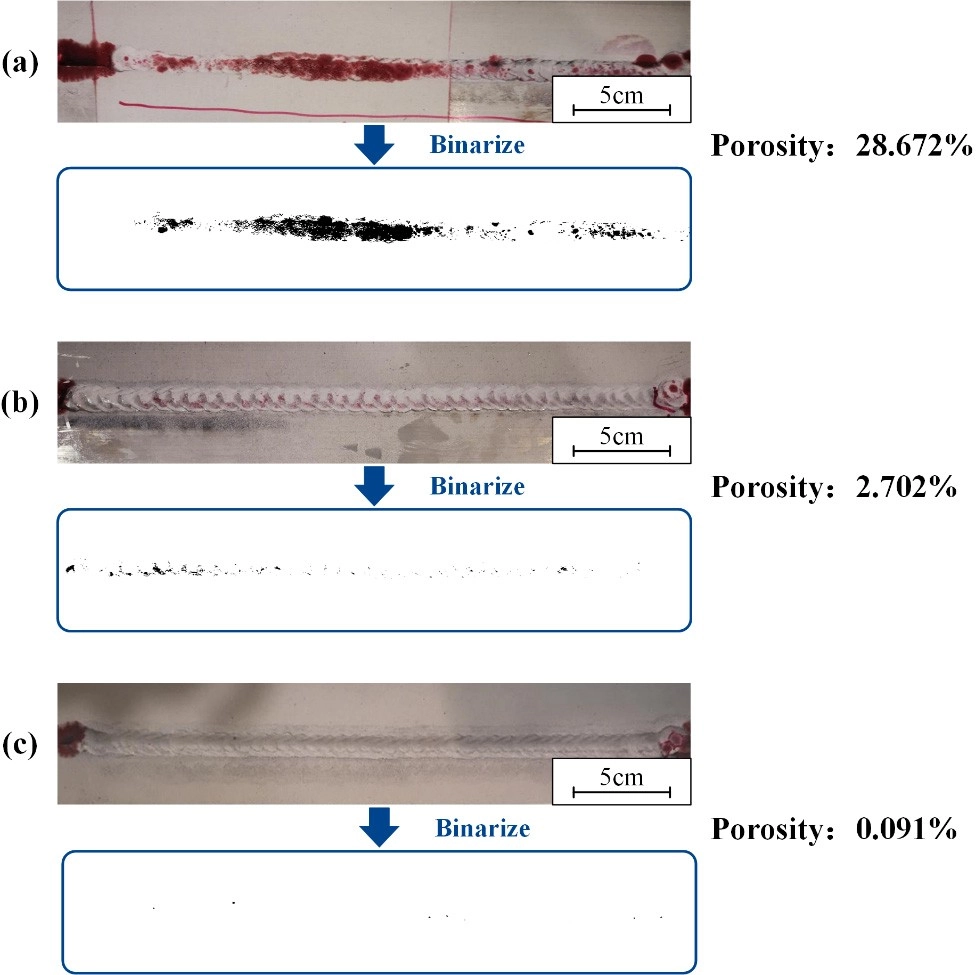

The Result of the Permeation Testing and The Porosity at Sample with: (a) Oil; (b) Water; (c)Laser Cleaning.

The thickness of the Aluminum alloy 5A06 oxide layer is 1–2 lm, and laser cleaning demonstrates a promising effect on the removal of the oxide for TIG welding.

Porosity was found in the fusion zone of TIG welds after normal ground, and inclusions with sharp morphology were examined as well.

After laser cleaning, no porosity existed in the fusion zone.

Moreover, the oxygen content decreased significantly, which is in agreement with previous results.

In addition, the thin layer of thermal melting occurred during laser cleaning, resulting in refined microstructure in the fusion zone.

View the Original Research Paper on Research Gate Here.

Or Check Out this Article We Published on: Laser Cleaning Aluminum (How Researchers Done it)

Want to Know about Laser Weld Cleaning?

We can Help!

What can I Use to Clean my Welds?

Cleaning Welds Provide Strong Bonds and Preventing Corrosion

Here are Some Traditional Methods for Cleaning Welds:

Description: Use a wire brush or wheel to remove slag, spatter, and oxides.

Pros: Inexpensive and effective for surface cleaning.

Cons: Can be labor-intensive and may not reach tight spots.

Description: Use a grinder to smooth out welds and remove imperfections.

Pros: Effective for heavy cleaning and shaping.

Cons: Can alter the weld profile and may introduce heat.

Description: Use acid-based solutions or solvents to dissolve contaminants.

Pros: Effective for tough residues and can be used in various applications.

Cons: Requires safety precautions and proper disposal.

Description: Propel abrasive material at high speed to remove contaminants.

Pros: Quick and effective for large areas.

Cons: Can cause surface erosion if not controlled.

Description: Use high-frequency sound waves in a cleaning solution to remove debris.

Pros: Reaches intricate shapes and removes contaminants thoroughly.

Cons: Equipment can be expensive & the cleaning size can be limited.

For Laser Ablation & Laser Surface Preparation:

Laser Ablation

Description: Use high-energy laser beams to vaporize contaminants without affecting the base material.

Pros: Precise, environmentally friendly, and effective for delicate applications.

Cons: Equipment can be costly, and requires skilled operation.

Laser Surface Preparation

Description: Use lasers to prepare surfaces by removing oxides and contaminants prior to welding.

Pros: Enhances weld quality and reduces defects.

Cons: Equipment can also be costly, and requires skilled operation.

How to Laser Clean Metal?

Laser Cleaning is an Efficient Method for Removing Contaminants

Wear appropriate PPE, including safety goggles, gloves, and protective clothing.

Secure the metal piece in a stable position to prevent movement during cleaning. Adjust the laser head to the recommended distance from the surface, typically between 10-30 mm.

Continuously monitor the cleaning process. Look for changes in the surface, such as the removal of contaminants or any damage to the metal.

After cleaning, inspect the weld area for cleanliness and any remaining contaminants. Depending on the application, consider applying a protective coating to prevent future corrosion.

What is the Best tool for Cleaning Welds?

Laser Cleaning Stands out as One of the Best Tools Available

For anyone involved in metal fabrication or maintenance, laser cleaning is an invaluable tool for cleaning welds.

Its precision, efficiency, and environmental benefits make it the optimal choice for achieving high-quality results while minimizing risks and downtime.

If you're looking to enhance your cleaning processes, consider investing in laser cleaning technology.

How do you Make Welds look Clean?

Laser Cleaning Helps Achieve Clean and Professional-looking Welds

Preparation of the Surface

Initial Cleaning: Before welding, ensure that the base metal is free of contaminants like rust, oil, and dirt. This step is crucial for achieving a clean weld.

Laser Cleaning: Use a laser cleaning system to effectively remove any surface impurities. The targeted approach ensures that only the contaminants are removed without damaging the metal.

Post-Weld Cleaning

Post-Weld Cleaning: After welding, promptly clean the weld area with a laser to remove slag, spatter, and oxidation that can detract from the weld's appearance.

Consistency: The laser cleaning process provides uniform results, ensuring that all welds have a consistent, clean finish.

Video Demonstrations: Laser Cleaning for Metal

What is Laser Cleaning & How it Works?

One of the biggest advantages of laser cleaning is that it is a dry process.

Which means there's no need for post-cleanup of debris.

Simply direct the laser beam at the surface you want to clean without affecting the underlying material.

Laser cleaners are also compact and portable, allowing for efficient on-site cleaning.

It typically requires only basic personal protective equipment, such as safety glasses and respirators.

Laser Ablation is Better at Rust Cleaning

Sandblasting can create a lot of dust and requires substantial cleanup.

Dry ice cleaning is potentially costly and less suited for large-scale operations.

Chemical cleaning may involve hazardous substances and disposal issues.

In contrast, laser cleaning emerges as a standout option.

It is incredibly versatile, handling a range of contaminants with precision

The process is cost-effective in the long run due to no material consumption and low maintenance requirements.

Handheld Laser Cleaning Machine: Laser Weld Cleaning

Pulsed Laser Cleaner (100W, 200W, 300W, 400W)

Pulsed fiber laser cleaners are particularly well-suited for cleaning delicate, sensitive, or thermally vulnerable surfaces, where the precise and controlled nature of the pulsed laser is essential for effective and damage-free cleaning.

Laser Power: 100-500W

Pulse Length Modulation: 10-350ns

Fiber Cable Length: 3-10m

Wavelength: 1064nm

Laser Source: Pulsed Fiber Laser

Laser Rust Removal Machine (Pre & Post Laser Weld Cleaning)

Laser weld cleaning is widely used in industries such as aerospace, automotive, shipbuilding, and electronics manufacturing where high-quality, defect-free welds are critical for safety, performance, and appearance.

Laser Power: 100-3000W

Adjustable Laser Pulse Frequency: Up to 1000KHz

Fiber Cable Length: 3-20m

Wavelength: 1064nm, 1070nm

Support Various Languages