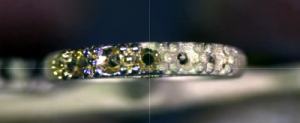

Laser Welding Jewelry Repair

Laser welding is a revolutionary technique that has transformed the jewelry industry.

When using a jewelry laser welding machine, jewelers can create precise, high-quality welds on a variety of metals, including gold, silver, and platinum, without compromising the integrity or appearance of the jewelry.

What is Laser Welding Jewelry?

Jewelry Laser Welding

The key advantage of laser welding for jewelry is its precision and control.

The laser beam can be focused on a tiny spot,

Allowing jewelers to weld delicate components

Without damaging the surrounding materials.

This makes it particularly useful for tasks like setting gemstones,

Repairing intricate metal engravings,

And assembling complex jewelry pieces.

Compared to Traditional Welding Methods:

Laser welding generates minimal heat, reducing the risk of deformation or material fatigue.

This is crucial when working with heat-sensitive stones like emeralds and opals.

Laser welding also eliminates the need for additional welding materials,

Creating a clean, seamless finish.

Jewelry laser welding machines are easy to use and can be integrated into automated production processes,

Improving efficiency and consistency.

They also have low maintenance costs,

Making them a practical investment for jewelry workshops and manufacturers.

What kind of Welding is Used for Jewelry?

Laser Welding Jewelry Repair

The most common types of welding used for jewelry are microresistance welding and laser welding.

Laser Welding:

Laser welding has also become increasingly popular in the jewelry industry.

Laser welding uses an amplified light beam to create nearly invisible joints in jewelry.

This method is known for its versatility, reliability, and speed

Laser welding can be used on a wide range of precious metals,

From sterling silver to platinum,

Without causing brittleness or damage.

Micro-resistance Welding:

Microresistance welding is a popular choice for jewelry applications.

This technique takes advantage of the resistivity of different metals to create a strong,

Precise weld without damaging the surrounding materials.

The controlled heat and small weld area make micro-resistance welding

Well-suited for delicate jewelry pieces.

Other Welding Methods:

Brazing Welding and Pulse Arc Welding are sometimes used for jewelry as well,

But are less common than micro resistance and laser welding.

Brazing involves using a filler material to join metals,

While pulse arc welding uses an electric pulse to weld the pieces together.

However, these techniques may not provide the same level of precision and control

Required for intricate jewelry designs.

Want to Know More about Laser Welding Jewelry?

We can Help!

How Accurate is Jewelry Laser Welder?

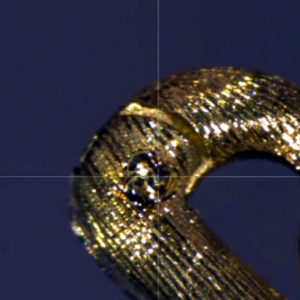

Accurate Jewelry Laser Welding

Jewelry laser welders are renowned for their exceptional accuracy and precision.

The focused laser beam allows jewelers to perform intricate and delicate repairs with pinpoint precision.

All about Accuracy and Control:

The laser's concentrated heat and ability to be adjusted from 0.2mm to 2mm in diameter

Gives jewelers complete control over where the laser is applied.

This allows them to work extremely close to heat-sensitive stones

Without causing any damage.

Jewelers can now routinely accomplish tasks that were

Previously impossible or too time-consuming using traditional soldering methods.

Game-Changer for the Jewelry Industry:

The accuracy of laser welding is a game-changer for the jewelry industry.

It enables jewelers to maintain the integrity and original appearance of antique pieces during repairs,

Without having to remove stones or risk damaging the delicate metalwork.

The laser can fuse metal together.

Without altering the patina or oxidating the original piece.

Accomplishing the Impossible:

For newer jewelry designs, the laser's precision is invaluable.

Jewelers can assemble complex, diamond-intensive pieces while keeping the intricate details intact,

Something that would be very difficult with a traditional torch.

The laser can also be used to quickly

And accurately repair defects like porosity holes without affecting the rest of the piece.

Can you Laser Weld Gold Jewelry?

Laser Welding Gold Jewelry

Yes, you can absolutely laser weld gold for jewelry.

Laser welding is a highly effective and precise technique

For working with gold and other precious metals in jewelry making and repair.

Key Benefits of Using Laser Welding for Gold Jewelry:

Versatility - Laser welders can handle a wide range of gold alloys, from 10K to 24K, as well as other precious metals like platinum and silver.

Minimal Heat Damage - Laser welding generates very localized heat, minimizing the "heat-affected zone" and reducing the risk of warping or discoloration of the gold.

Precision - The laser beam can be precisely targeted to weld tiny, intricate areas without affecting the rest of the piece.

This makes laser welding ideal for tasks like setting gemstones, repairing prongs, and assembling complex jewelry designs.

Speed and Efficiency - Laser welding is a fast process, allowing jewelers to complete repairs and assembly tasks more quickly than with traditional methods like soldering.

This can boost productivity in a jewelry workshop.

Can you Laser Weld Silver Jewelry?

Laser Welding Silver Jewelry

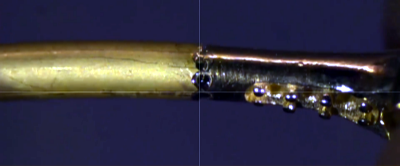

Yes, you can laser weld silver for jewelry making.

Silver requires higher laser power settings compared to other metals like gold or platinum.

The laser welder needs to be capable of at least 6 kilowatts of peak pulse power to effectively weld silver.

The welding process for silver generally takes longer than for other precious metals.

This is due to silver's higher surface tension.

Using an inert gas like argon or nitrogen during the laser welding process

Can help improve the weld quality and reduce contaminants.

The inert gas creates a protective "cloud" around the welding area.

Starts "Lower", Ends "Better":

When laser welding silver, it's best to use a slightly lower silver content filler wire,

Like "silver weld hard" wire, instead of pure 925 sterling silver.

The lower silver content allows the wire to flow better at lower voltage settings,

Reducing the risk of pitting or cracking.

It's important to start with lower voltage settings and work up gradually when laser welding silver.

This helps find the optimal temperature for each piece and creates stronger, more consistent welds.

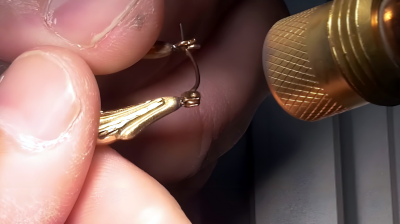

Jewelry Laser Welder

Stands out with its compact machine size and easy operability in jewelry repairing and ornament manufacturing.

For exquisite patterns and stubble details on the jewelry. You can handle these with the small laser welder after a little practice.

Compact Design for Accessibility.

Electronic Filter Protection for Eye Safety.

Intuitive Digital Control System.

Supports Air or Water Cooling.

Is Laser Welding Jewelry Repair better than Soldering?

When it comes to repairing jewelry, jewelers have two main options:

Laser Welding and Torch Soldering.

Both methods have their own advantages and disadvantages,

And the choice ultimately depends on the specific needs of the jewelry piece.

For Laser Welding:

Laser welding is generally considered the superior method for jewelry repair.

Unlike traditional soldering, laser welding allows jewelers to efficiently and effectively repair jewelry

Without removing heat-sensitive stones

And without the use of flux or lead solder.

The laser welding process is very clean, with no discoloration,

And it requires less time to refinish the piece.

Better Welding Strength & Versatility:

Laser welding also creates a stronger bond than soldering.

A good laser weld is three times as strong as the virgin metal,

Or 260 times stronger than a solder joint.

This makes laser-welded repairs more durable and less likely to fail over time.

Another advantage of laser welding is that it can be used on a wider range of materials,

Including gold-filled and gold-plated jewelry,

Which can be difficult to repair using traditional soldering methods.