Why do Research Yourself when We Have Done it for You?

Are you considering a laser cleaner for your business or personal use?

With the growing popularity of these innovative tools, it's essential to understand what to look for before making a purchase.

In this article, we'll guide you through the key factors to consider:

Including how to choose the right laser source for your needs

The importance of customization options

And what to keep in mind regarding packaging.

Whether you're a first-time buyer or looking to upgrade your equipment, this comprehensive guide will help you make an informed decision.

Are you looking for a Pulsed Laser Cleaner in Specific?

We recommend this article on how to choose a pulsed laser cleaner for you!

Applications of Laser Cleaning Machine

Handheld laser cleaning machines offer a range of practical applications across various industries.

Here are some specific use cases where these machines excel:

Before painting or coating, surfaces must be clean and free of contaminants.

Handheld laser cleaners effectively remove rust, oil, and old paint from metal surfaces, ensuring optimal adhesion for new finishes.

This process is particularly useful in automotive and manufacturing settings.

In art and historical preservation, handheld laser cleaning is invaluable for restoring sculptures, statues, and antiques.

The precision of the laser allows conservators to clean delicate surfaces without damaging the original material, effectively removing grime and oxidation.

Technicians use handheld laser cleaners to prepare metal parts for welding or repair.

They can quickly eliminate rust and contaminants from components such as frames and exhaust systems, enhancing the quality of repairs and extending the lifespan of the parts.

In aerospace, maintaining the integrity of components is crucial.

Handheld laser cleaning machines are used to remove contaminants from aircraft parts without abrasive methods that may cause damage.

This ensures safety and compliance with strict industry standards.

For sensitive electronic components, handheld laser cleaners provide a non-contact method to remove dust, residues, and oxidation.

This application is essential for maintaining the performance and reliability of electronic devices without risking damage from traditional cleaning methods.

In the marine industry, handheld laser cleaners are used to remove barnacles, algae, and rust from boat hulls.

This not only improves the appearance of vessels but also enhances their performance by reducing drag in the water.

Regular maintenance of industrial equipment is vital for efficiency.

Handheld laser cleaning machines can be used to clean machinery and tools, removing buildup that can affect performance.

This helps reduce downtime and prolongs equipment life.

In construction, these machines are used for cleaning surfaces before applying new materials or finishes.

They can effectively remove coatings, adhesives, and other contaminants from concrete, metal, and other surfaces, ensuring a clean base for new applications.

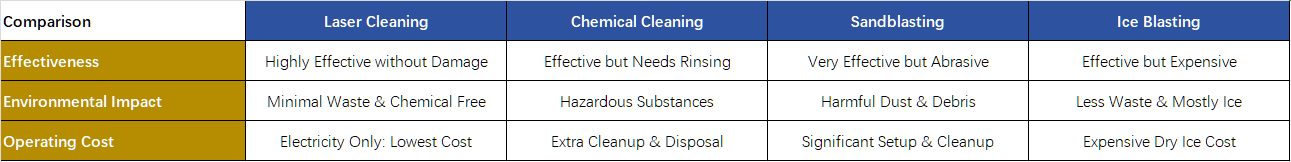

Comparison Between Different Cleaning Methods

Handheld laser cleaning machines offer a modern alternative to traditional cleaning methods such as chemical cleaning, sandblasting, and ice blasting.

Here’s a clear comparison of these approaches:

A Chart Showcasing the Comparison Between Different Cleaning Mehods

Want to Know More about Laser Cleaning Machines?

Start Chatting with Us Today!

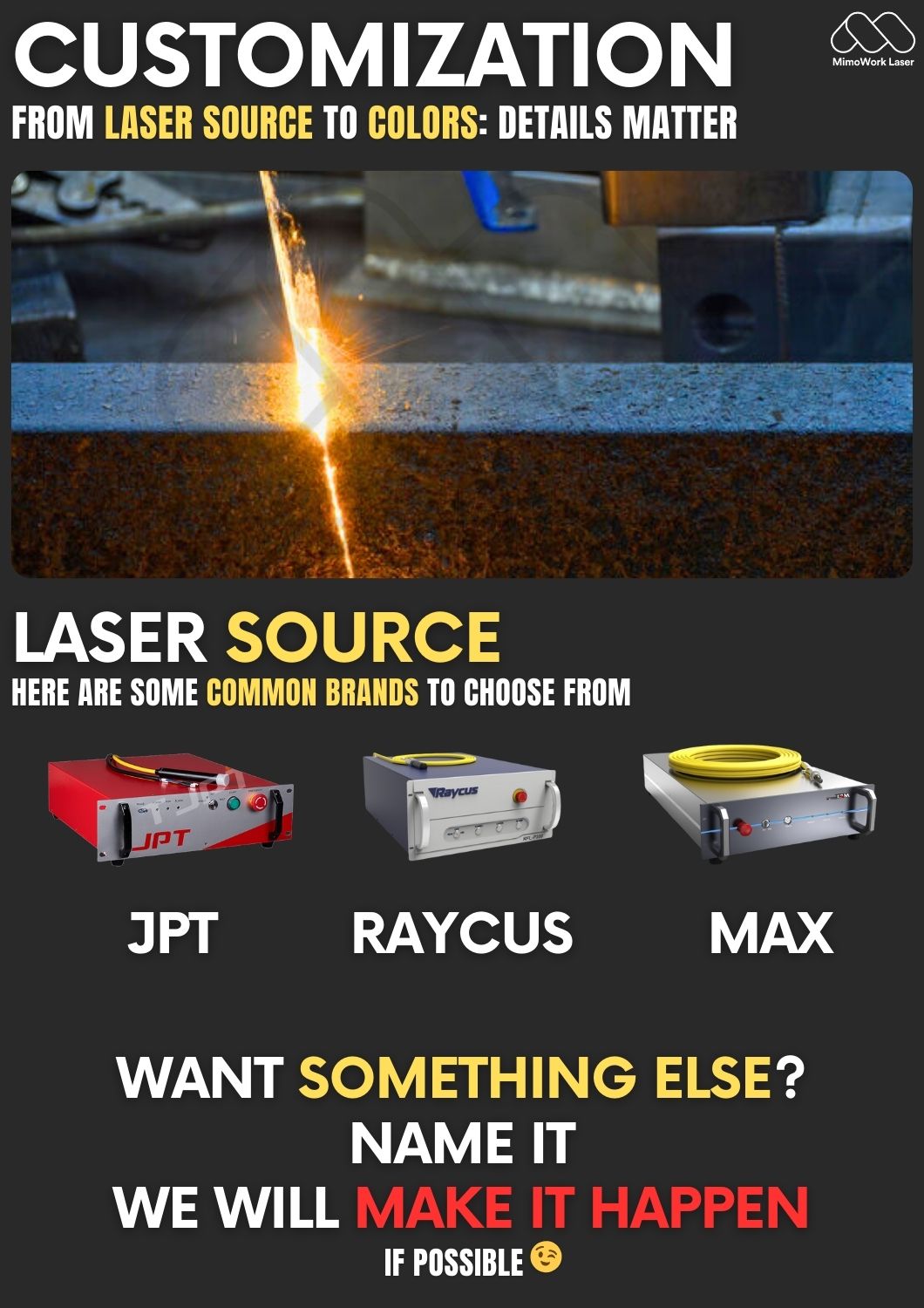

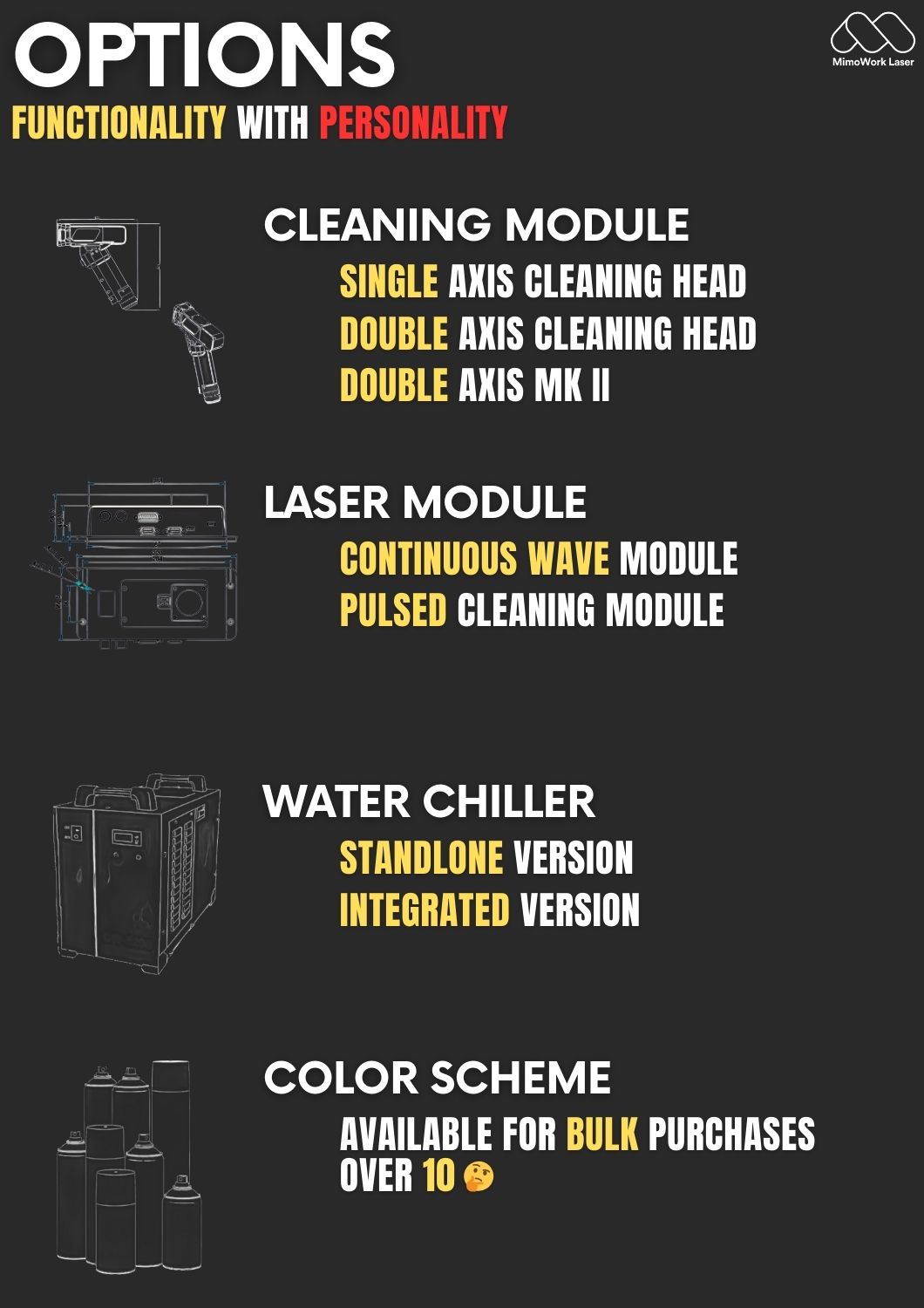

Customization & Options

We provide a wide range of customization options for our customers.

You can choose everything from the laser source and cleaning module to the laser module and water chiller.

Plus, if you order in bulk (10 units or more), you can even select your preferred color scheme!

Not sure what to pick? No worries!

Just let us know what materials you'll be cleaning, your containment thickness & type, and your desired cleaning speed.

We're here to help you create the perfect setup for your needs!

Accessories for Laser Cleaner

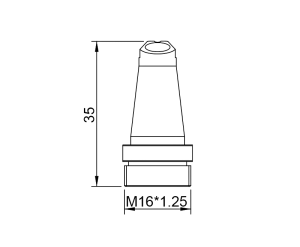

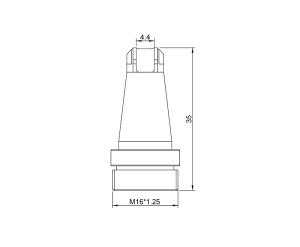

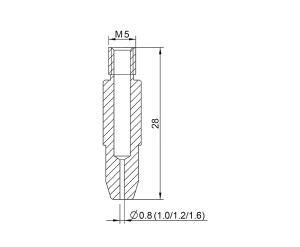

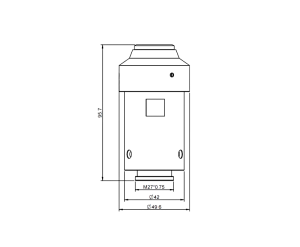

For accessories, we offer extra protective lenses and a variety of nozzles tailored for different welding & cleaning applications.

If you need detailed information or want to purchase additional accessories, feel free to chat with us!

A Selection of Different Nozzles for Laser Cleaning/ Welding Machine

Additional Information about Laser Cleaner

The pulsed fiber laser featuring high precision and no heat affection area usually can reach an excellent cleaning effect even if under a low power supply

| Power Option | 100w/ 200w/ 300w/ 500w |

| Pulse Frequency | 20kHz - 2000kHz |

| Pulse Length Modulation | 10ns - 350ns |

| Laser Type | Pulsed Fiber Laser |

| Trademark | MimoWork Laser |

Different from pulse laser cleaner, the continuous wave laser cleaning machine can reach higher-power output which means higher speed and larger cleaning covering space.

| Power Option | 1000w/ 1500w/ 2000w/ 3000w |

| Beam Width | 10-200nm |

| Max Scanning Speed | 7000mm/s |

| Laser Type | Continuous Wave |

| Trademark | MimoWork Laser |

Videos about Laser Cleaning

Handheld laser cleaning machines are advanced tools designed to remove contaminants, rust, and old coatings from surfaces using laser technology.

They work by directing a focused laser beam onto the material, which effectively vaporizes or dislodges unwanted substances without damaging the underlying surface.

Post time: Nov-05-2024