Why do Research Yourself when We Have Done it for You?

Thinking about investing in a handheld laser welder?

These versatile tools are revolutionizing the way welding is done, offering precision and efficiency for various projects.

However, before making a purchase, it's important to understand several key aspects.

In this article, we’ll cover everything you need to know,

including how to choose the right laser source based on your specific needs,

the available customization options to tailor the welder to your projects,

and other essential factors to consider.

Whether you're a hobbyist or a professional,

this guide will equip you with the knowledge to make an informed decision

and find the perfect handheld laser welder for your requirements.

Applications of Laser Welding Machine

Handheld laser welding machines have become increasingly popular due to their versatility and ease of use.

Here are some specific applications where these machines excel:

Handheld laser welders are ideal for small-scale metal fabrication projects.

They can easily join various metals, such as stainless steel, aluminum, and copper.

This capability is particularly useful for creating custom metal parts, prototypes, or intricate designs that require precision.

In the automotive industry, handheld laser welding machines are used for repairing bodywork and structural components.

Their ability to precisely weld thin materials without warping or damaging surrounding areas makes them perfect for fixing car panels, exhaust systems, and other metal parts.

Jewelry artisans benefit significantly from handheld laser welders.

These machines allow for detailed and accurate welding of precious metals, enabling jewelers to create intricate designs and repairs on delicate pieces without compromising their integrity.

For maintenance and repair tasks in various industries, handheld laser welding machines offer a portable solution.

Technicians can perform on-site repairs, such as welding fixtures, brackets, and other metal components, without needing to transport them to a workshop.

Artists and sculptors are increasingly turning to handheld laser welding for creating metal sculptures.

The ability to manipulate and join materials with precision allows for innovative artistic expressions and complex structures.

In HVAC and plumbing applications, handheld laser welders are used for joining pipes and fittings.

The ability to weld without additional filler materials ensures strong joints and reduces the risk of leaks in critical systems.

Small custom fabrication shops benefit from the flexibility of handheld laser welding machines.

They can quickly adapt to various projects, producing everything from custom furniture to specialized tools with high precision.

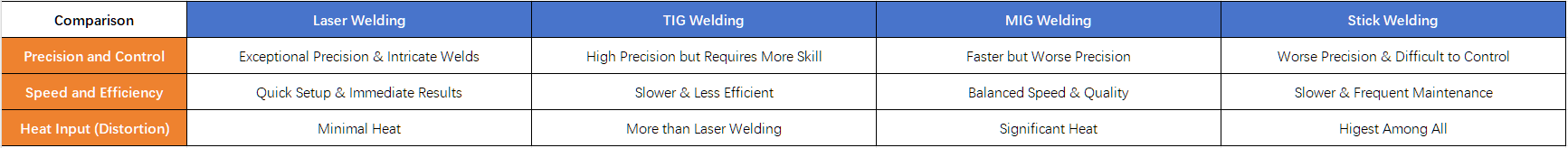

Comparison Between Different Welding Methods

Handheld laser welding machines present a modern solution for welding tasks,

offering distinct advantages over traditional methods such as TIG, MIG, and Stick welding.

Here’s a straightforward comparison of these welding techniques:

A Chart Showcasing the Comparison Between Different Welding Mehods

Want to Know More about Laser Welding Machines?

Start Chatting with Us Today!

Customization & Options

We provide a wide range of customization options for our customers.

You can choose everything from the laser source and cleaning module to the laser module and water chiller.

Plus, if you order in bulk (10 units or more), you can even select your preferred color scheme!

Laser Source Selection

JPT is a prominent manufacturer known for its high-quality laser sources, particularly in the field of fiber laser technology.

They offer a range of products suitable for various applications, including welding, cutting, and marking.

JPT lasers are recognized for their reliability and performance, providing stable outputs and efficient energy consumption.

The company focuses on innovation, continuously improving its products to meet industry demands.

Their customer support and service are generally well-regarded, making them a popular choice among users.

RAYCUS is another leading producer of fiber laser sources, with a strong presence in both domestic and international markets.

They specialize in developing and manufacturing laser systems that cater to a wide array of industrial applications, such as cutting, engraving, and welding.

RAYCUS lasers are known for their competitive pricing and solid performance, appealing to a broad range of customers.

The company emphasizes research and development, striving to enhance the efficiency and capability of its laser sources while maintaining good quality control standards.

MAX is a reputable brand in the laser source industry, particularly recognized for its advanced fiber laser technology.

They offer a variety of laser sources designed for applications like marking, engraving, and cutting.

MAX lasers are noted for their high precision and excellent beam quality, contributing to superior results in various tasks.

The company also places a strong emphasis on customer service and support, ensuring users receive assistance when needed.

MAX is often praised for its innovative approach and commitment to delivering reliable and efficient laser solutions.

Want something else?

Name it!

We will make it happen!

(If possible.)

Customization Options

1. Single Axis Swing Module

2. Double Axis Swing Module

3. SuperCharged Module

For Automatic Filler Wire Feeding During Welding Operation.

1. Standalone Version

2. Integrated Verson

Available for Bule Purchases over 10

Not sure what to pick? No worries!

Just let us know what materials you'll be working with, their thickness, and your desired welding speed.

We're here to help you create the perfect setup for your needs!

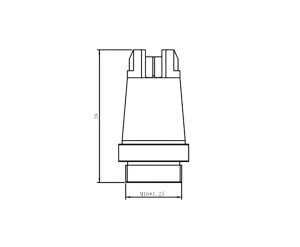

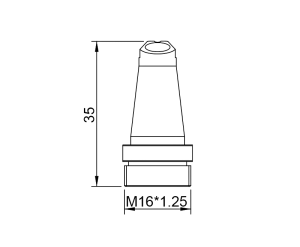

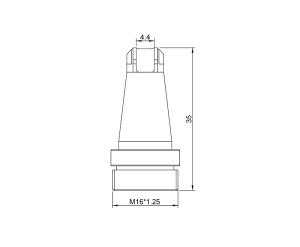

Accessories for Laser Welder

For accessories, we offer extra protective lenses and a variety of nozzles tailored for different welding applications.

If you need detailed information or want to purchase additional accessories, feel free to chat with us!

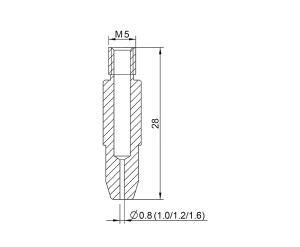

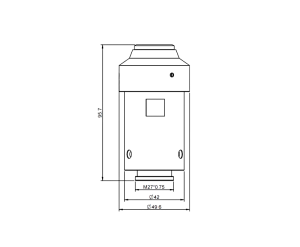

A Selection of Different Nozzles for Laser Cleaning/ Welding Machine

Additional Information about Laser Welder

Unlike traditional welding methods, these machines use focused laser beams to create strong, clean welds with minimal heat distortion.

| Power Option | 500W- 3000W |

| Working Mode | Continuous/ Modulate |

| Laser Classification | Optical Fiber Laser |

| Cooling Method | Industrial Water Chiller |

| Trademark | MimoWork Laser |

With a compact and small machine appearance, equipped with a moveable welder gun which is lightweight and convenient for multi-laser welding applications at any angle and surface.

| Power Option | 1000W - 1500W |

| Working Mode | Continuous/ Modulate |

| Welding Speed | 0~120 mm/s |

| Weld Seam Requirements | <0.2mm |

| Trademark | MimoWork Laser |

Videos about Laser Welding

Handheld laser welding machines are innovative tools designed for precise and efficient welding of metals.

They are portable and user-friendly, making them suitable for a variety of applications, from automotive repairs to jewelry making.

With the ability to weld thin materials and intricate designs, handheld laser welders are ideal for small-scale projects that require accuracy.

Their versatility allows users to work on-site, reducing the need for extensive setups or heavy machinery.

As a result, they are increasingly popular among professionals and hobbyists looking for reliable and effective welding solutions.

Post time: Nov-06-2024