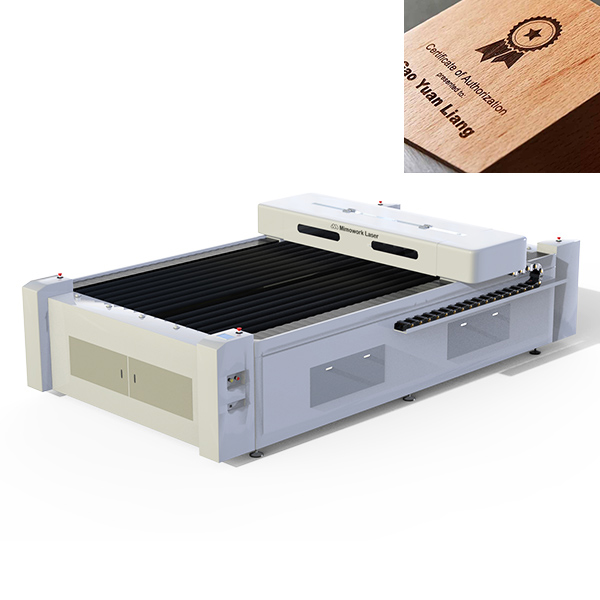

Professional Laser Solution for Cutting & Engraving

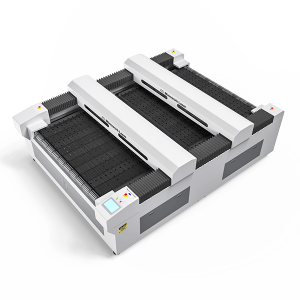

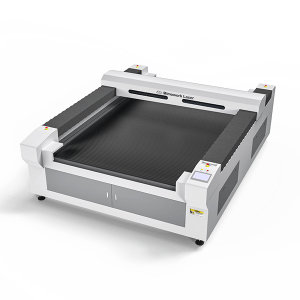

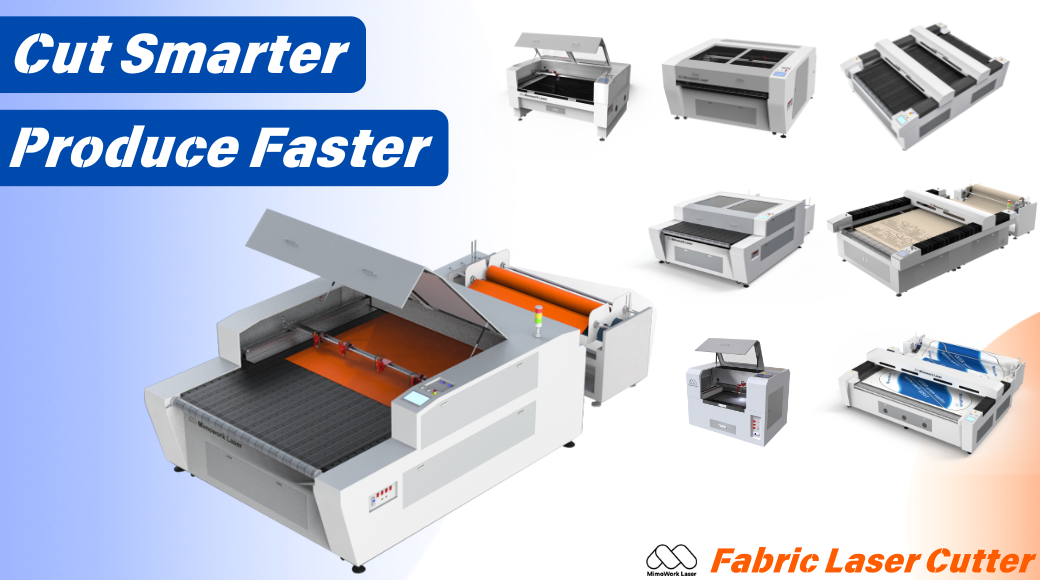

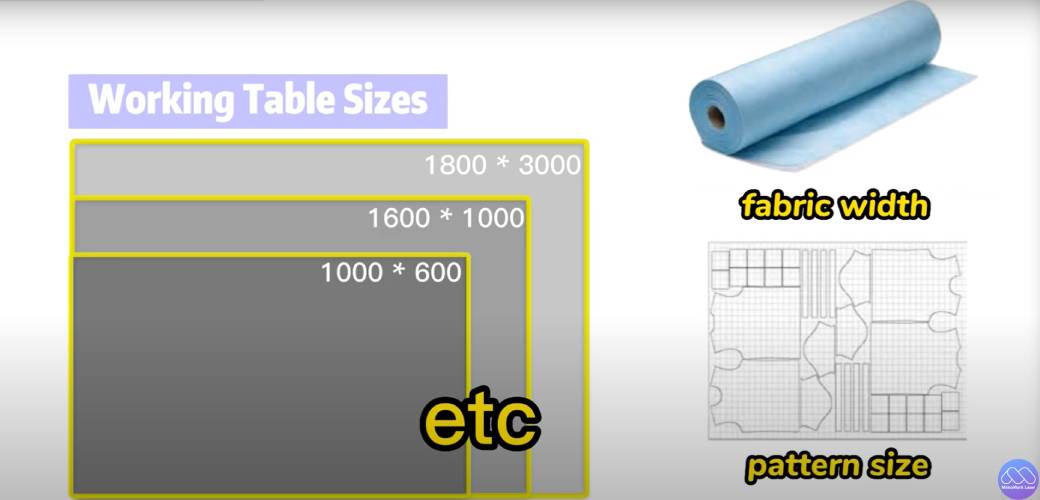

Combined with the CNC system(Computer Numerical Control) and advanced laser technology, the fabric laser cutter is given outstanding advantages, it can achieve automatic processing and precise & fast & clean laser cutting and tangible laser engraving on various fabrics. MimoWork Laser developed 4 most common and popular CO2 laser cutting machines for fabric and leather. The working table sizes are 1600mm * 1000mm, 1800mm * 1000mm, 1600mm * 3000mm, and 1800mm * 3000mm.

Thanks to the auto-feeder and conveyor table, the CO2 laser cutting machine with an auto-feeding system is suitable for most roll fabric cutting. The fabric laser cutting machine can also engrave fabrics, textiles, and leather by adjusting the laser power and speed. Suitable materials are cotton, Cordura, Kevlar, canvas fabric, nylon, silk, fleece, felt, film, foam, Alancantra, genuine leather, PU leather and others.

|

Model |

Working Table Size (W * L) |

Laser Power |

Machine Size (W*L*H) |

|

F-6040 |

600mm * 400mm |

60W |

1400mm*915mm*1200mm |

|

F-1060 |

1000mm * 600mm |

60W/80W/100W |

1700mm*1150mm*1200mm |

|

F-1390 |

1300mm * 900mm |

80W/100W/130W/150W/300W |

1900mm*1450mm*1200mm |

|

F-1325 |

1300mm * 2500mm |

150W/300W/450W/600W |

2050mm*3555mm*1130mm |

|

F-1530 |

1500mm * 3000mm |

150W/300W/450W/600W |

2250mm*4055mm*1130mm |

|

F-1610 |

1600mm * 1000mm |

100W/130W/150W/300W |

2210mm*2120mm*1200mm |

|

F-1810 |

1800mm * 1000mm |

100W/130W/150W/300W |

2410mm*2120mm*1200mm |

|

F-1630 |

1600mm * 3000mm |

150W/300W |

2110mm*4352mm*1223mm |

|

F-1830 |

1800mm * 3000mm |

150W/300W |

2280mm*4352mm*1223mm |

|

C-1612 |

1600mm * 1200mm |

100W/130W/150W |

2300mm*2180mm*2500mm |

|

C-1814 |

1800mm * 1400mm |

100W/130W/150W |

2500mm*2380mm*2500mm |

|

Laser Type |

CO2 Glass Laser Tube/ CO2 RF Laser Tube |

|

Max Cutting Speed |

36,000mm/min |

|

Max Engraving Speed |

64,000mm/min |

|

Motion System |

Servo Motor/Hybrid Servo Motor/Step Motor |

|

Transmission System |

Belt transmission /Gear & Rack Transmission / Ball Screw Transmission |

|

Work Table Type |

Mild Steel Conveyor Working Table /Honeycomb Laser Cutting Table /Knife Strip Laser Cutting Table /Shuttle Table |

|

Number of Laser Head |

Conditional 1/2/3/4/6/8 |

|

Focal Length |

38.1/50.8/63.5/101.6mm |

|

Location Precision |

±0.015mm |

|

Min Line Width |

0.15-0.3mm |

|

Cooling Mode |

Water Cooling and Protection System |

|

Operation System |

Windows |

|

Controlling System |

DSP High Speed Controller |

|

Graphic Format Support |

AI, PLT, BMP, DXF, DST, TGA, etc |

|

Power Source |

110V/220V(±10%), 50HZ/60HZ |

|

Gross Power |

<1250W |

|

Working Temperature |

0-35℃/32-95℉ (22℃/72℉ recommended) |

|

Working Humidity |

20%~80% (non-condensing) relative humidity with 50% recommended for optimal performance |

|

Machine Standard |

CE, FDA, ROHS, ISO-9001 |

How to Choose the CO2 Laser Cutter Suits You?

When we say CO2 laser cutting machine for fabric and leather, we are not simply talking about a laser cutting machine that can cut fabric, we mean the laser cutter that comes with conveyor belt, auto feeder and all other necessary components help you cut fabric from roll automatically.

1. Working Table Size

|

Materials & Applications |

Clothing Line, Like Uniform, Blouse |

Industrial Fabrics like Cordura, Nylon, Kevlar |

Apparel Accessory, Like Lace and Woven Label |

Other Special Requirements |

|

Working Table Size |

1600*1000, 1800*1000 |

1600*3000, 1800*3000 |

1000*600 |

Customized |

2. Laser Power

|

Material Types |

cotton, felt, linen, canvas and polyester fabric |

Leather |

Cordura, Kevlar, Nylon |

Fiber Glass Fabric |

|

Recommended Power |

100W |

100W to 150W |

150W to 300W |

300W to 600W |

3. Cutting Efficiency

For laser cutting fabrics and textiles, the best way to increase the cutting efficiency is to equip the multiple laser heads.

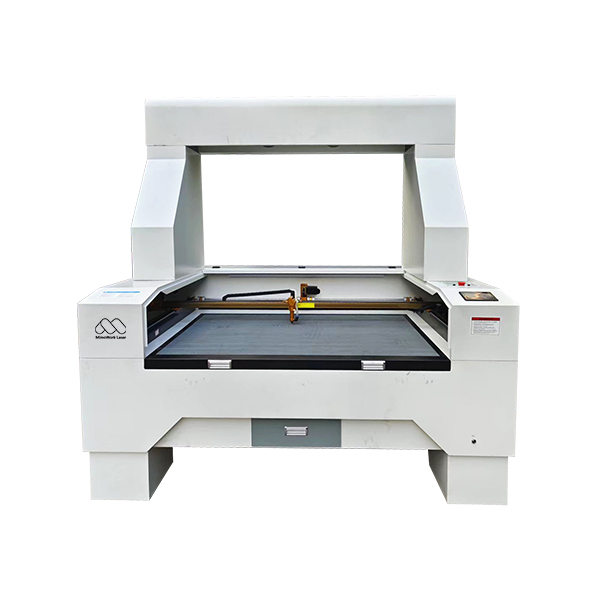

Laser Machine Features

1. Linear Guideway

Linear rail guides are essential components that facilitate smooth, straight-line motion in various machinery. They are designed to carry loads while minimizing friction, ensuring stability and precision in movement.

2. Control Panel

The touch-screen panel makes it easier to adjust the parameters. You can directly monitor amperage (mA) and water temperature right from the display screen.

3. USA Focus Lens

CO2 USA laser focus lenses are precision optical components designed specifically for CO2 laser systems. These lenses play a crucial role in directing and focusing the laser beam onto the material being processed, ensuring optimal cutting, engraving, or marking performance. Made from high-quality materials such as zinc selenide or glass, CO2 focus lenses are engineered to withstand the intense heat generated during laser operations while maintaining clarity and durability.

4. Servo Motor

Servo motors ensure higher speed and higher precision of laser cutting and engraving. A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position.

5. Exhaust Fan

Exhaust fans are crucial components in fabric laser cutting machines, designed to maintain a safe and efficient working environment. Their primary function is to remove smoke, fumes, and particulate matter generated during the laser cutting process.

6. Air Blower

Air assistance is significant for you to ensure smooth production. We put the air assist next to the laser head, it can clear off the fumes and particles during laser cutting.

For another, the air assist can decrease the temperature of the processing area (that is called the heat-affected area), leading to a clean and flat cutting edge.

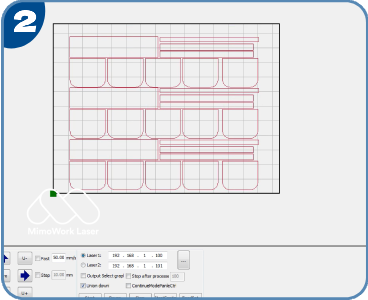

7. Laser Software(optional)

Choosing the suitable laser software can upgrade your production. Our MimoNEST software is a good choice for cutting patterns of different shapes and sizes, auto nesting the patterns to max the material use and cutting efficiency, more information about laser software, please talk with our laser expert.

Laser Machine Details

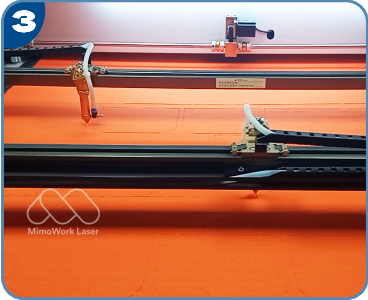

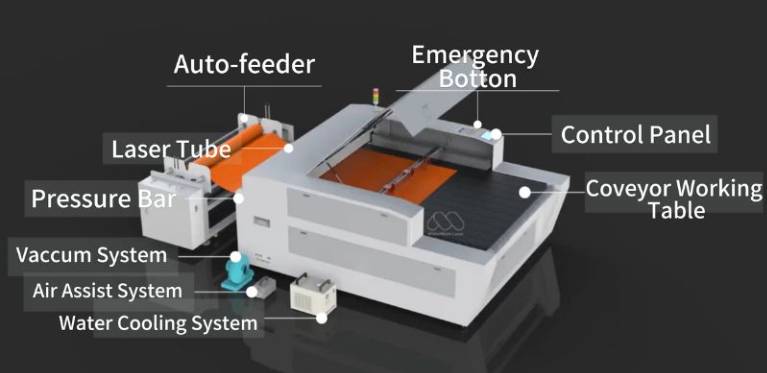

• Conveyor System: automatically transmits roll fabric to the table with auto-feeder and conveyor table.

• Laser Tube: the laser beam is produced here. And CO2 laser glass tube and RF tube are optional according to your needs.

• Vacuum System: combined with an exhaust fan, the vacuum table can suck the fabric to keep it flat.

• Air Assist System: the air blower can timely remove the fume and dust during laser cutting fabric or other materials.

• Water Cooling System: water circulation system can cool down the laser tube and other laser components to keep them safe and prolong service life.

• Pressure Bar: an auxiliary device that helps to keep the fabric flat and conveying smoothly.

MimoWork Laser - Company Information

Mimowork is a results-oriented laser manufacturer, based in Shanghai and Dongguan China.

With 20-year deep operational expertise, we produce laser systems and offer comprehensive processing and production solutions to SMEs (small and medium-sized enterprises) in a wide array of industries.

We offer:

✔ A Wide Range of Laser Machine Types for Fabric, Acrylic, Wood, Leather, etc.

✔ Customized Laser Solution

✔ Professional Guidance from Pre-Sales Consultant to Operation Training

✔ Online Video Meeting

✔ Material Testing

✔ Options and Spare Parts for Laser Machines

✔ Follow up by Special Person in English

✔ Worldwide Client Reference

✔ YouTube Video Tutorial

✔ Operation Manual

Certificate & Patent

FAQ

• What fabrics are safe for laser cutting?

Most Fabrics.

Fabrics that are safe for laser cutting include natural materials like cotton, silk, and linen, as well as synthetic fabrics such as polyester and nylon. These materials typically cut well without producing harmful fumes. However, for fabrics with high synthetic content, like vinyl or those containing chlorine, you need to be extra careful to clear away the fumes using a professional fume extractor, as they can release toxic gases when burned. Always ensure proper ventilation and refer to manufacturer guidelines for safe-cutting practices.

• How much is a laser cutting machine?

Basic CO2 laser cutters range in price from below $2,000 to over $200,000. The price difference is quite large when it comes to the different configurations of CO2 laser cutters. To understand the cost of a laser machine, you need to consider more than the initial price tag. You should also consider the overall cost of owning a laser machine throughout its lifetime, to better evaluate whether it’s worth investing in a piece of laser equipment. Details about laser cutting machine prices to check out the page: How Much Does A Laser Machine Cost?

• How does laser cutting machine work?

The laser beam starts from the laser source, and is directed and focused by the mirrors and focus lens to the laser head, then shot onto the material. The CNC system controls the laser beam generation, the power and pulse of the laser, and the cutting path of the laser head. Combined with the air blower, exhaust fan, motion device and working table, the basic laser cutting process can be finished smoothly.

• Which gas is used in laser cutting machine?

There are two parts that need the gas: the resonator and the laser cutting head. For the resonator, the gas including high-purity (grade 5 or better) CO2, nitrogen, and helium are required to produce the laser beam. But usually, you don't need to replace these gases. For the cutting head, the nitrogen or oxygen assist gas is required to help protect the material to be processed and improve the laser beam to reach the optimal cutting effect.

OPERATION

How To Use Laser Cutting Machine?

Laser Cutting Machine is an intelligent and automatic machine, with the support of a CNC system and laser cutting software, the laser machine can deal with complex graphics and plan the optimal cutting path automatically. You just need to import the cutting file to the laser system, select or set the laser cutting parameters like speed and power, and press the start button. The laser cutter will finish the rest of the cutting process. Thanks to the perfect cutting edge with a smooth edge and clean surface, you do not need to trim or polish the finished pieces. The laser cutting process is fast and the operation is easy and friendly to beginners.

▶ Example : Laser Cutting Roll Fabric

Step 1. Put the Roll Fabric on the Auto-Feeder

Prepare the Fabric: Put the roll fabric on the auto feeding system, keep the fabric flat and edge neat, and start the auto feeder, place the roll fabric on the convertor table.

Laser Machine: Choose the fabric laser cutting machine with an auto feeder and conveyor table. The machine working area needs to match the fabric format.

▶

Step 2. Import the Cutting File & Set the Laser Parameters

Design File: Import the cutting file to the laser cutting software.

Set the Parameters: In general, you need to set the laser power and laser speed according to material thickness, density, and the requirements for cutting precision. Thinner materials require lower power, you can test laser speed to find an optimal cutting effect.

▶

Step 3. Start Laser Cutting Fabric

Laser Cut: It's available for multiple laser cutting heads, you can choose two laser heads in one gantry, or two laser heads in two independent gantry. That is different from laser cutting productivity. You need to discuss with our laser expert about your cutting pattern.

The Large Format Laser Cutting Machine is designed for ultra-long fabrics and textiles. With a 10-meters long and 1.5-meters wide working table, the large format laser cutter is suitable for most fabric sheets and rolls like tent, parachute, kitesurfing, aviation carpet, advertising pelmet and signage, sailing cloth and etc...

The CO2 laser cutting machine is equipped with a projector system with an accurate positioning function. The preview of the workpiece to be cut or engraved helps you to place the material in the right area, enabling the post-laser cutting and laser engraving to go smoothly and with high accuracy...

> What information you need to provide?

> Our contact information

Quickly Learn More:

Dive into the Magic World of CO2 Laser Cutting Machine,

Discuss with our Laser Expert!

Post time: Nov-04-2024