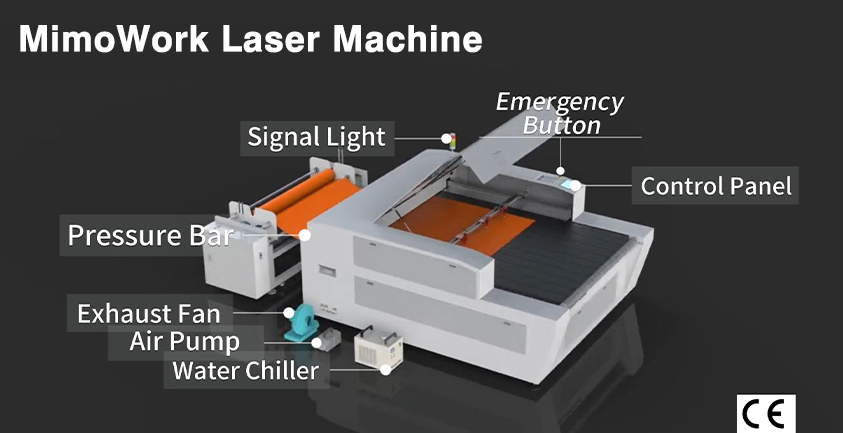

A laser cutting machine system is generally composed of a laser generator, (external) beam transmission components, a worktable (machine tool), a microcomputer numerical control cabinet, a cooler and computer (hardware and software), and other parts. Everything has a shelf life, and the laser cutting machine is not immune to glitches over time.

Today, we will explain to you a few small tips on checking your CO2 laser cutting engraving machine, saving your time and money from hiring local technicians.

Five Circumstances and how to deal with these

▶ No response after powering on, you need to check

1. Whether the power fuse is burned out: replace the fuse

2. Whether the main power switch is damaged: replace the main power switch

3. Whether the power input is normal: use a voltmeter to check the power consumption to see if it meets the machine’s standard

▶ Disconnection from the computer, you need to check

1. Whether the scanning switch is on: Turn on the scanning switch

2. Whether the signal cable is loose: Plug the signal cable and secure it

3. Whether the drive system is connected: check the power supply of the drive system

4. Whether the DSP motion control card is damaged: repair or replace the DSP motion control card

▶ No laser output or weak laser shooting, you need to check

1. Whether the optical path is offset: do the optical path calibration monthly

2. Whether the reflection mirror is polluted or damaged: clean or replace the mirror, soak in the alcoholic solution if necessary

3. Whether the focus lens is polluted: clean the focusing lens with Q-tip or replace a new one

4. Whether the focus length of the device changes: readjust the focus length

5. Whether the cooling water quality or water temperature is normal: replace the clean cooling water and check the signal light, add refrigerating fluid in extreme weather

6. Whether the water chiller works functionally: dredge the cooling water

7. Whether the laser tube is damaged or aging: check with your technician and replace a new CO2 glass laser tube

8. Whether the laser power supply is connected: check the laser power supply loop and tighten it

9. Whether the laser power supply is damaged: repair or replace the laser power supply

▶ Imprecise slider movement, you need to check

1. Whether the trolley slide and slider are polluted: clean the slide and slider

2. Whether the guide rail is polluted: clean the guide rail and add lubricating oil

3. Whether the transmission gear is loose: tighten the transmission gear

4. Whether the transmission belt is loose: adjust the belt tightness

▶ Undesired cutting or carving depth, you need to check

1. Adjust the cutting or engraving parameters setting under the suggestion of MimoWork Laser Technicians. >> Contact Us

2. Choose better material with fewer impurities, the laser absorption rate of the material with more impurities will be unstable.

3. If the laser output becomes weak: increase the laser power percentage.

Any questions about how to use laser machines and products details

Post time: Oct-21-2022