The fiber laser and CO2 laser are the common and popular laser types.

They are widely used in a dozen of applications like cutting metal and non-metal, engraving and marking.

But the fiber laser and CO2 laser are different among many features.

We need to know the differences between fiber laser vs. CO2 laser, then make a wise choice about choosing which one.

This article will focus on these to help you buy a suitable laser machine.

If you don't have a purchase plan yet, that's all right. This article is also helpful to have more knowledge.

After all, better safe than sorry.

What is CO2 Laser?

A CO2 laser is a type of gas laser that uses a carbon dioxide gas mixture as the active laser medium.

Electricity excites CO2 gas, which then emits infrared light at 10.6 micrometers wavelength.

Characteristics:

Suitable for non-metal materials like wood, acrylic, leather, fabric, and paper.

Versatile and widely used in industries such as signage, textiles, and packaging.

Offers excellent beam quality for precise cutting and engraving.

What is Fiber Laser?

A fiber laser is a type of solid-state laser that uses an optical fiber doped with rare-earth elements as the laser medium.

Fiber lasers use diodes to excite the doped fiber, producing laser light at various wavelengths (commonly 1.06 micrometers).

Characteristics:

Ideal for metal materials such as steel, aluminum, copper, and alloys.

Known for high energy efficiency and precise cutting capabilities.

Fast cutting speeds and superior edge quality on metals.

CO2 Laser VS. Fiber Laser: Laser Source

CO2 laser marking machine uses CO2 laser

Fiber laser marking machine uses fiber laser.

The carbon dioxide laser wavelength is 10.64μm, and the optical fiber laser wavelength is 1064nm.

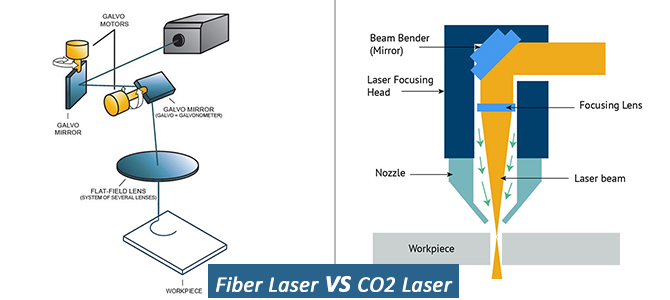

The optical fiber laser relies on the optical fiber to conduct the laser, while the CO2 laser needs to conduct the laser by the external optical path system.

Therefore, the optical path of the CO2 laser needs to be adjusted before each device is used, while the optical fiber laser does not need to be adjusted.

A CO2 laser engraver uses a CO2 laser tube to produce a laser beam.

The main working medium is CO2, and O2, He, and Xe are auxiliary gases.

The CO2 laser beam is reflected by the reflecting and focusing lens and focused onto the laser cutting head.

Fiber laser machines generate laser beams through multiple diode pumps.

The laser beam is then transmitted to the laser cutting head, laser marking head and laser welding head through a flexible fiber optic cable.

CO2 Laser VS. Fiber Laser: Materials & Applications

The beam wavelength of a CO2 laser is 10.64um, which is easier to be absorbed by non-metallic materials.

However, the wavelength of the fiber laser beam is 1.064um, which is 10 times shorter.

Because of this smaller focal length, the fiber laser cutter is almost 100 times stronger than a CO2 laser cutter with the same power output.

So fiber laser cutting machine, as known as a metal laser cutting machine, is very suitable for cutting metal materials, such as stainless steel, carbon steel, galvanized steel, copper, aluminum, and so on.

CO2 laser engraving machine can cut and carve metal materials, but not so efficiently.

It also involves the absorption rate of the material to different wavelengths of the laser.

The characteristics of the material determine which type of laser source is the best tool to process.

The CO2 laser machine is mainly used for cutting and engraving non-metallic materials.

For example, wood, acrylic, paper, leather, fabric, and so on.

Seek a suitable laser machine for your application

The lifespan of a fiber laser can reach 100,000 hours, the lifespan of a solid-state CO2 laser can reach 20,000 hours, glass laser tube can reach 3,000 hours. So you need to replace the CO2 laser tube every few years.

How to Choose CO2 or Fiber Laser?

Choosing between a fiber laser and a CO2 laser depends on your specific needs and applications.

Choosing Fiber Laser

If you are working with metal materials like stainless steel, aluminum, copper, etc.

Whether cutting or marking on these, fiber laser is almost your only choice.

Besides, if you want to get plastic engraved or marked, the fiber is feasible.

Choosing CO2 Laser

If you are engaged in cutting and engraving non-metal like acrylic, wood, fabric, leather, paper and others,

choosing CO2 laser is definitely a perfect choice.

Besides, for some coated or painted metal sheet, the CO2 laser is able to engrave on that.

Learn more about fiber laser and CO2 laser and receptive laser machine

Post time: Jul-12-2024