As a professional laser machine supplier, we are well aware that there are many puzzles and questions about laser cutting wood. The article is focused on your concern about wood laser cutter! Let's jump into it and we believe you will get a great and complete knowledge of that.

Can Laser Cut Wood?

Yes! Laser cutting wood is a highly effective and precise method. Wood Laser cutting machine uses a high-powered laser beam to vaporize or burn away material from the surface of the wood. It's widely used in various industries, including woodworking, crafting, manufacturing, and more. The laser's intense heat results in clean and sharp cuts, making it perfect for intricate designs, delicate patterns, and precise shapes.

Let's further talk about it!

▶ What is Laser Cutting Wood

First, we need to know what is laser cutting and how it works. Laser cutting is a technology that uses a high-powered laser to cut or engrave materials with a high level of precision and accuracy. In laser cutting, a focused laser beam, often generated by a carbon dioxide (CO2) or fiber laser, is directed onto the material's surface. The intense heat from the laser vaporizes or melts the material at the point of contact, creating a precise cut or engraving.

For laser cutting wood, the laser is like a knife that cuts through the wood board. Differently, the laser is more powerful and with higher precision. Via the CNC system, the laser beam will position the right cutting path according to your design file. The magic starts: the focused laser beam is directed onto the wood's surface, and the laser beam with high heat energy can instantly vaporize (to be specific - sublimated) the wood from surface to bottom. Superfine laser beam (0.3mm) totally covers almost all wood cutting requirements whether you want a higher efficiency production or a higher precise cutting. This process creates precise cuts, intricate patterns, and fine details on the wood.

>> Check out the videos about laser cutting wood:

Any ideas about laser cutting wood?

▶ CO2 VS Fiber Laser: which one suits cutting wood

For cutting wood, a CO2 Laser is definitely the best choice due to its inherent optical property.

As you can see in the table, CO2 lasers typically produce a focused beam at a wavelength of around 10.6 micrometers, which is readily absorbed by wood. However, fiber lasers operate at a wavelength of around 1 micrometer, which is not fully absorbed by wood compared to CO2 lasers. So if you want to cut or mark on metal, the fiber laser is great. But for these non-metal like wood, acrylic, textile, CO2 laser cutting effect is incomparable.

▶ Wood Types Suitable for Laser Cutting

✔ MDF

✔ Plywood

✔ Balsa

✔ Hardwood

✔ Softwood

✔ Veneer

✔ Bamboo

✔ Balsa Wood

✔ Basswood

✔ Cork

✔ Timber

✔ Cherry

Pine, Laminated Wood, Beech, Cherry, Coniferous Wood, Mahogany, Multiplex, Natural Wood, Oak, Obeche, Teak, Walnut and more. Almost all wood can be laser cut and the laser cutting wood effect is excellent.

But if the wood to be cut is adhered to toxic film or paint, safety precautions are necessary while laser cutting. If you are not sure, it is best to inquire with a laser expert.

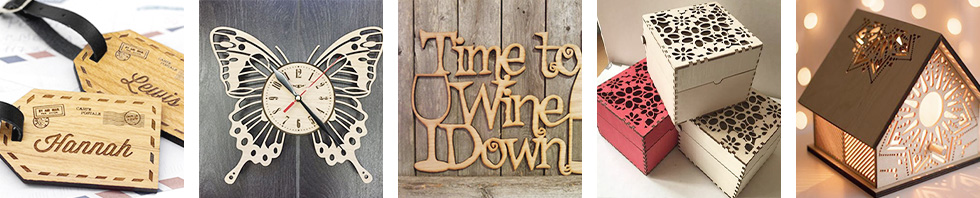

♡ Sample Gallery of Laser Cut Wood

• Wood Tag

• Crafts

• Wood Sign

• Storage Box

• Architectural Models

• Wood Wall Art

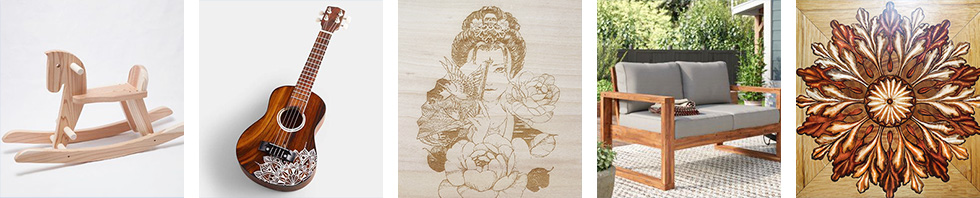

• Toys

• Instruments

• Wooden Photos

• Furniture

• Veneer Inlays

• Die Boards

Video 1: Laser Cut & Engrave Wood Decoration - Iron Man

Video 2: Laser Cutting A Wood Photo Frame

MimoWork Laser

MimoWork Laser Series

▶ Popular Wood Laser Cutter Types

Working Table Size: 600mm * 400mm (23.6” * 15.7”)

Laser Power Options: 65W

Overview of Desktop Laser Cutter 60

The Flatbed Laser Cutter 60 is a desktop model. Its compact design minimizes the space requirements of your room. You can conveniently place it on a table for use, making it an excellent entry-level option for startups dealing with small custom products.

Working Table Size: 1300mm * 900mm (51.2” * 35.4 ”)

Laser Power Options: 100W/150W/300W

Overview of Flatbed Laser Cutter 130

The Flatbed Laser Cutter 130 is the most popular choice for wood cutting. Its front-to-back through-type work table design enables you to cut wooden boards longer than the working area. Moreover, it offers versatility by equipping with laser tubes of any power rating to meet the needs for cutting wood with different thicknesses.

Working Table Size: 1300mm * 2500mm (51.2” * 98.4”)

Laser Power Options: 150W/300W/500W

Overview of Flatbed Laser Cutter 130L

The Flatbed Laser Cutter 130L is a large-format machine. It is suitable for cutting large wooden boards, such as the commonly found 4ft x 8ft boards in the market. It primarily caters to larger products, making it a favored choice in industries like advertising and furniture.

▶ Advantages of Laser Cutting Wood

Intricate cut pattern

Clean & flat edge

Constant cutting effect

✔ Clean and Smooth Edges

Powerful and precise laser beam vaporizes the wood, resulting in clean and smooth edges that require minimal post-processing.

✔ Minimal Material Waste

Laser cutting minimizes material waste by optimizing the layout of cuts, making it a more eco-friendly option.

✔ Efficient Prototyping

Laser cutting is ideal for rapid prototyping and testing designs before committing to mass and custom production.

✔ No Tool Wear

Laser cutting MDF is a non-contact process, which eliminates the need for tool replacement or sharpening.

✔ Versatility

Laser cutting can handle a wide range of designs, from simple shapes to intricate patterns, making it suitable for various applications and industries.

✔ Intricate Joinery

Laser cut wood can be designed with intricate joinery, allowing for precise interlocking parts in furniture and other assemblies.

Case Study from Our Clients

★★★★★

♡ John from Italy

★★★★★

♡ Eleanor from Australia

★★★★★

♡ Michael from America

Be A Partner with Us!

Learn about us >>

Mimowork is a results-oriented laser manufacturer, based in Shanghai and Dongguan China, bringing 20 years of deep operational expertise to produce laser systems and offer comprehensive processing…

▶ Machine Information: Wood Laser Cutter

What is a laser cutter for wood?

A laser cutting machine is a type of auto CNC machinery. The laser beam is generated from the laser source, focused to become powerful through the optical system, then shot out from the laser head, and finally, the mechanical structure allows the laser to move for cutting materials. The cutting will keep the same as the file you imported into the operation software of the machine, to achieve precise cutting.

The wood laser cutter has a pass-through design so that any length of wood can be held. The air blower behind the laser head is significant for excellent cutting effect. Besides wonderful cutting quality, safety can be guaranteed thanks to signal lights and emergency devices.

▶ 3 Factors You Need to Consider When Buying Machine

When you want to invest in a laser machine, there are 3 main factors you need to consider. According to the size and thickness of your material, working table size and laser tube power can be basically confirmed. Combined with your other productivity requirements, you can choose suitable options to upgrade laser productivity. Besides you need to concern about your budget.

Different models come with varying work table sizes, and the work table size determines what size of wooden sheets you can place and cut on the machine. Therefore, you need to select a model with an appropriate work table size based on the sizes of the wooden sheets you intend to cut.

E.g., if your wooden sheet size is 4 feet by 8 feet, the most suitable machine would be our Flatbed 130L, which has a work table size of 1300mm x 2500mm. More Laser Machine types to check out the product list >.

The laser power of the laser tube determines the maximum thickness of wood that the machine can cut and the speed at which it operates. In general, higher laser power results in greater cutting thickness and speed, but it also comes at a higher cost.

E.g., if you want to cut MDF wood sheets. we recommend:

Additionally, budget and available space are crucial considerations. At MimoWork, we offer free but comprehensive pre-sales consultation services. Our sales team can recommend the most suitable and cost-effective solutions based on your specific situation and requirements.

Get More Advice about Wood Laser Cutting Machine Purchase

Laser wood cutting is a simple and automatic process. You need to prepare the material and find a proper wood laser cutting machine. After importing the cutting file, the wood laser cutter starts cutting according to the given path. Wait a few moments, take out the wood pieces, and do your creations.

Step 1. prepare machine and wood

▼

Wood Preparation: choose a clean and flat wood sheet without a knot.

Wood Laser Cutter: based on wood thickness and pattern size to select co2 laser cutter. Thicker wood requires a higher-power laser.

Some Attention

• keep wood clean & flat and in suitable moisture.

• best to make a material test before actual cutting.

• higher-density wood requires high power, so inquire us for expert laser advice.

Step 2. set software

▼

Design File: import the cutting file to the software.

Laser Speed: Begin with a moderate speed setting (e.g., 10-20 mm/s). Adjust the speed based on the complexity of the design and the precision required.

Laser Power: Start with a lower power setting (e.g., 10-20%) as a baseline, Gradually increase the power setting in small increments (e.g., 5-10%) until you achieve the desired cutting depth.

Some you need to know: ensure that your design is in a vector format (e.g., DXF, AI). Details to check out the page: Mimo-Cut software.

Step 3. laser cut wood

Start Laser Cutting: start the laser machine, the laser head will find the right position and cut the pattern according to the design file.

(You can watch over to ensure the laser machine is well done.)

Tips and Tricks

• use masking tape on the wood surface to avoid fumes and dust.

• keep your hand away from the laser path.

• remember to open the exhaust fan for great ventilation.

✧ Done! You will get an excellent and exquisite wood project! ♡♡

▶ Real Laser Cutting Wood Process

Laser Cutting 3D Puzzle Eiffel Tower

• Materials: Basswood

• Laser Cutter: 1390 Flatbed Laser Cutter

This video demonstrated Laser Cutting American Basswood to make a 3D Basswood Puzzle Eiffel Tower Model. Mass production of 3D Basswood Puzzles is Conveniently made possible with a Basswood Laser Cutter.

The laser cutting basswood process is fast and precise. Thanks to the fine laser beam, you can get accurate pieces to fit together. Suitable air blowing is important to ensure a clean edge without burning.

• What you get from laser cutting basswood?

After cutting, all pieces can be packaged and sold as a product for profit, or if you would like to assemble the pieces yourself, the final assembled model would look great and very presentable in a showcase or on a shelf.

# How long does it take to laser cut wood?

In general, a CO2 laser cutting machine with 300W power can reach a high speed of up to 600mm/s. Specific time spent relies on specific laser machine power and the size of the design pattern. If you want to estimate the working time, send your material information to our salesman, and we will give you a test and yield estimation.

Start Your Wood Business and Free Creation with the wood laser cutter,

Act now, enjoy it right away!

FAQ about Laser Cutting Wood

▶ How thick of wood can laser cut?

The maximum thickness of wood that can be cut using laser technology is contingent upon a combination of factors, primarily the laser power output and the specific characteristics of the wood being processed.

Laser power is a pivotal parameter in determining the cutting capabilities. You can reference the power parameters table below to determine the cutting capabilities for various thicknesses of wood. Importantly, in situations where different power levels can cut through the same thickness of wood, the cutting speed becomes a crucial factor in selecting the appropriate power based on the cutting efficiency you aim to achieve.

Challange laser cutting potential >>

(up to 25mm Thickness)

Suggestion:

When cutting various types of wood at different thicknesses, you can refer to the parameters outlined in the table above to select an appropriate laser power. If your specific wood type or thickness does not align with the values in the table, please don't hesitate to reach out to us at MimoWork Laser. We will be happy to provide cutting tests to assist you in determining the most suitable laser power configuration.

▶ Can a laser engraver cut wood?

Yes, a CO2 laser engraver can cut wood. CO2 lasers are versatile and commonly used for both engraving and cutting wood materials. The high-powered CO2 laser beam can be focused to cut through wood with precision and efficiency, making it a popular choice for woodworking, crafting, and various other applications.

▶ Difference between cnc and laser for cutting wood?

CNC Routers

Laser Cutters

In summary, CNC routers offer depth control and are ideal for 3D and detailed woodworking projects. Laser cutters, on the other hand, are all about precision and intricate cuts, making them a top choice for precise designs and sharp edges. The choice between the two depends on the specific requirements of the woodworking project.

▶ Who should buy a wood laser cutter?

Both wood laser cutting machines and CNC routers can be invaluable assets for woodcraft businesses. These two tools complement each other rather than compete. If your budget allows, consider investing in both to enhance your production capabilities, though I understand that may not be feasible for most.

◾ If your primary task involves intricate carving and cutting wood up to 30mm in thickness, a CO2 laser cutting machine is the optimal choice.

◾ However, if you're part of the furniture industry and require cutting thicker wood for load-bearing purposes, CNC routers are the way to go.

◾ Given the wide range of laser functions available, if you're an enthusiast of wooden craft gifts or just starting your new business, we recommend exploring desktop laser engraving machines that can easily fit on any studio table. This initial investment typically starts at around $3000.

☏ Wait to hear from you!

Start A Laser Consultant Now!

> What information you need to provide?

|

✔ |

Specific Material (such as plywood, MDF) |

|

✔ |

Material Size and Thickness |

|

✔ |

What You Want to Laser To Do? (cut, perforate, or engrave) |

|

✔ |

Maximum Format to be processed |

> Our contact information

You can find us via Facebook, YouTube, and Linkedin.

Dive Deeper ▷

You may be interested in

# how much does a wood laser cutter cost?

# how to choose working table for laser cutting wood?

# how to find the right focal length for laser cutting wood?

# what else material can laser cut?

Any confusion or questions for the wood laser cutter, just inquire us at any time

Post time: Oct-16-2023