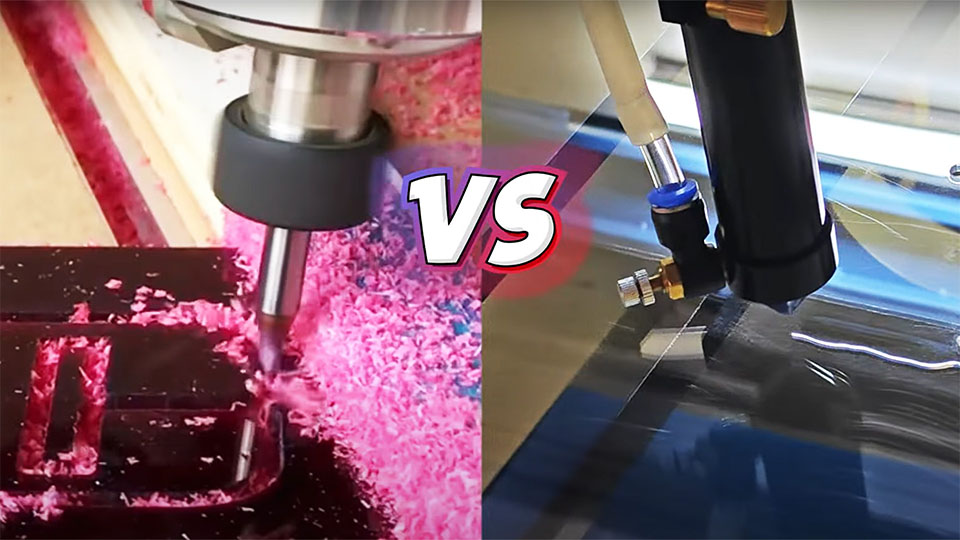

When it comes to acrylic cutting and engraving, CNC routers and lasers are often compared. Which one is better? The truth is, they are different but complement each other by playing unique roles in different fields. What are these differences? And how should you choose? Get through the article and tell us your answer.

How It Work? CNC Acrylic Cutting

The CNC router is a traditional and widely-used cutting tool. A variety of bits can handle cutting and engraving acrylic at different depths and precisions. CNC routers can cut acrylic sheets up to 50mm thick, which is great for advertising letters and 3D signage. However, CNC-cut acrylic needs to be polished afterward. As one CNC expert said, 'One minute to cut, six minutes to polish.' This is time-consuming. Plus, replacing bits and setting various parameters like RPM, IPM, and feed rate increases the learning and labor costs. The worst part is the dust and debris everywhere, which can be hazardous if inhaled.

In contrast, laser cutting acrylic is cleaner and safer.

How It Work? Laser Cutting Acrylic

Besides a clean cutting and safe working environment, laser cutters offer higher cutting and engraving precision with a beam as thin as 0.3mm, which CNC cannot match. No polishing or bit changing is required, and with less cleanup, laser cutting only takes 1/3 of the time of CNC milling. However, laser cutting has thickness limitations. Generally, we recommend cutting acrylic within 20mm to achieve the best quality.

So, who should choose a laser cutter? And who should choose a CNC?

Who Should Choose CNC Router?

• Mechanics Geek

If you have experience in mechanical engineering and can handle complex parameters like RPM, feed rate, flutes, and tip shapes (cue animation of CNC router surrounded by technical terms with a 'brain-fried' look), a CNC router is a great choice.

• For Cutting Thick Material

It’s ideal for cutting thick acrylic, more than 20mm, making it perfect for 3D letters or thick aquarium panels.

• For Deep Engraving

CNC router excels in deep engraving tasks, such as stamp engraving, thanks to its strong mechanical milling.

Who Should Choose Laser Router?

• For Precise Tasks

Ideal for tasks requiring high precision. For acrylic die boards, medical parts, car and airplane dashboards, and LGP, a laser cutter can achieve 0.3mm precision.

• High Transparency Required

For clear acrylic projects like lightboxes, LED display panels, and dashboards, lasers ensure unmatched clarity and transparency.

• Start-Up

For businesses focusing on small, high-value items like jewelry, art pieces, or trophies, a laser cutter offers simplicity and flexibility for customization, creating rich and fine details.

There are two standard laser cutting machines for you: Small acrylic laser engravers (for cutting and engraving) and large format acrylic sheet laser cutting machines (that can cut thicker acrylic up to 20mm).

1. Small Acrylic Laser Cutter & Engaraver

• Working Area (W * L): 1300mm * 900mm (51.2” * 35.4 ”)

• Laser Power: 100W/150W/300W

• Laser Source: CO2 Glass Laser Tube or CO2 RF Metal Laser Tube

• Max Cutting Speed: 400mm/s

• Max Engraving Speed: 2000mm/s

The flatbed laser cutter 130 is perfect for small items cutting and engraving, like keychain, decorations. Easy to use and perfect for intricate design.

2. Large Acrylic Sheet Laser Cutter

• Working Area (W * L): 1300mm * 2500mm (51” * 98.4”)

• Laser Power: 150W/300W/450W

• Laser Source: CO2 Glass Laser Tube or CO2 RF Metal Laser Tube

• Max Cutting Speed: 600mm/s

• Position Accuracy: ≤±0.05mm

The flatbed laser cutter 130L is perfect for large format acrylic sheet or thick acrylic. Good at handling advertising signage, showcase. Larger working size, but clean and accurate cuts.

If you have special requirements like engraving on cylindrical items, cutting sprues, or special automotive parts, consult us for professional laser advice. We are here to help you!

Video Explanation: CNC Router VS Laser Cutter

In summary, CNC routers can handle thicker acrylic, up to 50mm, and offer versatility with different bits but require post-cut polishing and produce dust. Laser cutters provide cleaner, more precise cuts, no need for tool replacement, and no tool wear. But, if you need to cut acrylic thicker than 25mm, lasers won't help.

So, CNC VS. Laser, which one is better for your acrylic production? Share your insights with us!

1. What is the difference between CNC acrylic and laser cutting?

CNC routers use a rotating cutting tool to physically remove material, suitable for thicker acrylic (up to 50mm) but often require polishing. Laser cutters use a laser beam to melt or vaporize the material, offering higher precision and cleaner edges without the need for polishing, best for thinner acrylic (up to 20-25mm).

2. Is laser cutting better than CNC?

Laser cutters and CNC routers excel in different areas. Laser cutters offer higher precision and cleaner cuts, ideal for intricate designs and fine details. CNC routers can handle thicker materials and are better for deep engraving and 3D projects. Your choice depends on your specific needs.

3. What does CNC mean in laser cutting?

In laser cutting, CNC stands for "Computer Numerical Control." It refers to the automated control of the laser cutter using a computer, which precisely directs the movement and operation of the laser beam to cut or engrave materials.

4. How fast is CNC compared to laser?

CNC routers typically cut thicker materials faster than laser cutters. However, laser cutters are faster for detailed and intricate designs on thinner materials, as they don't require tool changes and offer cleaner cuts with less post-processing.

5. Why can't diode laser cut acrylic?

Diode lasers can struggle with acrylic due to wavelength issues, especially with clear or light-colored materials that don't absorb the laser light well. If you attempt to cut or engrave acrylic with a diode laser, it's best to test first and be prepared for potential failure, as finding the right settings can be challenging. For engraving, you might try spraying a layer of paint or applying a film to the acrylic surface, but overall, I recommend using a CO2 laser for the best results.

What's more, diode lasers can cut some dark, opaque acrylic. However, they cannot cut or engrave clear acrylic because the material doesn't absorb the laser beam effectively. Specifically, a blue-light diode laser cannot cut or engrave blue acrylic for the same reason: the matching color prevents proper absorption.

6. Which laser is best for cutting acrylic?

The best laser for cutting acrylic is a CO2 laser. It provides clean, precise cuts and is capable of cutting various thicknesses of acrylic effectively. CO2 lasers are highly efficient and suitable for both clear and colored acrylic, making them the preferred choice for professional and high-quality acrylic cutting and engraving.

Choose the suitable machine for your acrylic production! Any questions, consult us!

Post time: Jul-27-2024