If you're looking for an advanced and efficient solution for cleaning various surfaces in industrial or commercial settings, a handheld laser cleaner can be your ideal choice.

These innovative machines use high-energy laser beams to effectively remove rust, oxides, and other contaminants from a wide range of materials, including metals, stone, and delicate artifacts.

Whether it's rust removal, mold cleaning, paint stripping, or pre-treatment for welding, a handheld laser cleaner can handle even the most challenging tasks without the need for harsh chemicals or abrasive materials.

Here’s what you need to know to learn how to use a handheld laser cleaner safely and effectively for a wide range of applications.

How Does Handheld Laser Cleaner work?

A handheld laser cleaner operates by emitting a high-energy laser beam that targets and removes contaminants from the surface of various materials.

The laser beam delivers concentrated energy to the surface, causing the contaminants—such as rust, paint, or dirt—to vaporize or disintegrate through a process called laser ablation.

This method is highly precise and efficient, eliminating the need for chemicals or abrasive materials that might damage the underlying surface.

The laser beam is guided to the surface via an optical delivery system, which includes mirrors and lenses, ensuring accurate and controlled cleaning. Additionally, many handheld laser cleaners are equipped with a vacuum or extraction system to capture and collect the removed debris, maintaining a clean work environment.

Unlike traditional cleaning methods, which can be labor-intensive and may involve hazardous chemicals, laser cleaning is an environmentally friendly solution.

It effectively removes rust, paint, oxides, and other contaminants from both metal and non-metal surfaces, offering a safer and more sustainable alternative for industrial and commercial applications.

Types of Laser Cleaning Machines

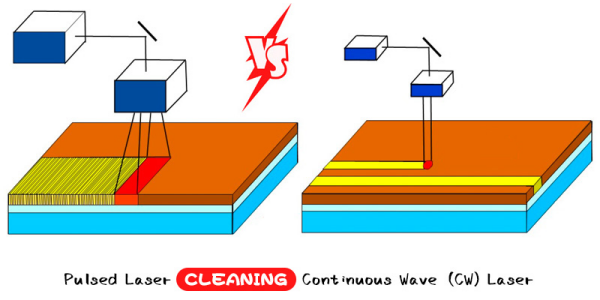

Continuous Wave Vs Pulsed Laser Cleaning Machine

Laser cleaning machines are classified into two main types based on their laser operation: continuous wave (CW) lasers and pulsed lasers. Both types have distinct applications and advantages.

It effectively removes rust, paint, oxides, and other contaminants from both metal and non-metal surfaces, offering a safer and more sustainable alternative for industrial and commercial applications.

Continuous Wave Laser Cleaning Machines

Continuous-wave lasers emit a constant laser beam without interruption.

They provide steady energy output, making them suitable for large-scale cleaning where precision is not critical.

Advantages:

1. Higher average power for faster cleaning of thick contaminants.

2. Suitable for removing rust, paint, and coatings over broad surfaces.

3. More cost-effective for industrial cleaning applications.

Limitations:

1. It can generate more heat, posing a risk of damaging heat-sensitive substrates.

2. Less suitable for intricate or selective cleaning tasks.

Pulsed Laser Cleaning Machines

Pulsed lasers emit short bursts of high-energy laser pulses.

Each pulse delivers energy for a very brief period, allowing for precise cleaning with minimal thermal impact.

Advantages:

1. Ideal for delicate surfaces where heat damage must be avoided.

2. Provides precise control for selective cleaning of small or complex areas.

3. Effective for removing thin films, oxidation, or light residues.

Limitations:

1. Generally more expensive than continuous wave lasers.

2. Requires careful parameter control to achieve optimal results.

Advantages of Handheld Laser Cleaner for Rust Removal

Laser Cleaning Steel

These advantages make handheld laser rust removal machine an ideal choice for rust removal, enhancing cleaning efficiency, reducing costs, and meeting the demands of high-quality cleaning requirements.

Efficient Cleaning

Handheld laser rust cleaning machine utilize high-energy laser beams for efficient and rapid rust removal.

The high-energy laser beam effectively breaks down and removes rust layers.

Compared to traditional cleaning methods, laser cleaning saves significant time and labor costs.

Non-contact Cleaning

It is a non-contact cleaning technique, ensuring that the laser beam does not physically touch the object’s surface during the cleaning process.

This means that the cleaning process does not cause damage or deformation to the object, making it particularly suitable for applications with stringent surface requirements.

Precise Positioning and Cleaning

Handheld laser rust cleaner offer precise positioning and control capabilities.

Operators can use the handheld device to precisely position and control the laser beam, focusing it on the rusted areas that require cleaning.

This enables localized cleaning while avoiding unnecessary cleaning of surrounding areas.

Environmentally Friendly

Fiber laser rust removal machine eliminate the need for chemical cleaning agents or solvents, reducing environmental pollution.

The laser cleaning process does not generate wastewater, emissions, or waste materials, aligning with environmental protection and sustainable development requirements.

Versatility Materials

Handheld laser rust removal machine are suitable for cleaning various materials, including metals, plastics, and stone.

Laser beam parameters can be adjusted based on the characteristics of different materials, ensuring efficient cleaning results.

Safety

Handheld laser rust remover are designed to be safe and reliable, with user-friendly operation.

They are typically equipped with safety features such as protective eyewear and safety switches on the handheld device, ensuring the safety of operators and the surrounding environment.

Buying a Pulsed Laser Cleaner? Not Before Watching This

Discover the Differences Between Pulsed and Continuous Wave Laser Cleaners!

Are you curious about the distinctions between pulsed and continuous wave laser cleaners?

In our quick, engaging animated explainer video, we’ll cover:

1. Learn about the various surfaces and materials suitable for pulsed laser cleaning.

2. Find out why pulsed laser cleaners are ideal for aluminum, while continuous wave cleaners are not.

3. Understand which laser settings have the greatest impact on your cleaning effectiveness.

4. Discover how to effectively remove paint from wood using a pulsed laser cleaner.

5. Get a clear explanation of the differences between single-mode and multi-mode lasers.

Handheld Laser Cleaning Machine: A Perfect Fit for All Workshops

Get One Now

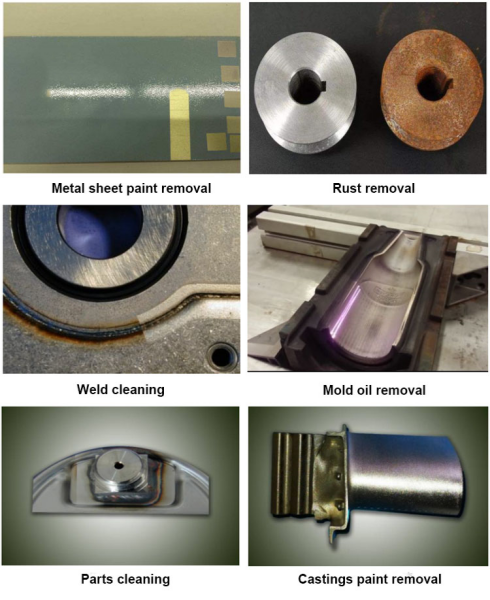

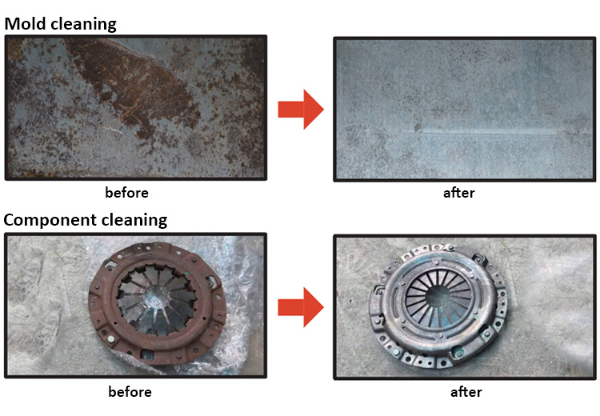

Handheld Laser Cleaning Machine Applications

Even irregular-shaped metal components can undergo rust removal with a laser rust remover.

Anywhere the laser can reach, it can remove surface rust, oil stains, paint layers, or oxidation. Therefore, in areas where tight spaces or difficult-to-reach tools pose challenges, hand held laser cleaning offers unparalleled advantages.

As laser technology is most effective for cleaning small, cleaning larger surface areas may take more time and might not yield optimal results.

Laser Cleaning Application & Examples

Automotive and Marine Bodies

Laser rust removal machine effectively removes oil residue from areas such as the engine compartment, wheel hubs, and chassis. It also targets debris and dust in hard-to-reach corners, achieving a thorough automotive cleaning. Laser descale machine tackles issues that traditional methods may struggle with.

Aluminum Products

Laser rust removal swiftly eliminates oxidation, rust spots, and burrs from the surface of aluminum products, resulting in improved polishing effects and enhanced surface quality.

Electronic Components

The technology can remove oxidation layers from the surfaces of electronic components, enhancing their conductivity and energy efficiency, thereby extending their lifespan.

Pre-coating with Laser cleaning

If you are welding the components until you paint them, the oxides must be cleaned to protect the coating from weakening over time.

Steel Structures

Laser rust cleaner can easily eliminate rust and oil stains on the surface of steel, significantly extending the lifespan of steel structures. It also activates the surface, enhancing the adhesion capability for subsequent coatings.

Pre-welding with Laser Cleaning

Utilizing a laser descaling apparatus has the potential to enhance the caliber of welded components.

Following the laser rust removal process, the presence of pores in the welded joints substantially reduces. Consequently, the welded joints exhibit elevated levels of yield strength, tensile strength, ductility, and resistance to fatigue.

Pre-Welding Before & After Laser Cleaning

Want To Know More About Handheld Laser Cleaning?

Start a Conversation Now!

How to use the Hand-held Laser Cleaner?

Using a handheld laser cleaner requires careful preparation and adherence to safety protocols. Here is a step-by-step guide to help you get started:

1. Equipment Inspection and Safety Preparation

1. Safety Gear: Wear appropriate personal protective equipment (PPE), including laser safety goggles, gloves, and protective clothing.

2. Work Area Setup: Ensure the work area is well-lit, ventilated, and free from flammable materials. Set up barriers or enclosures to contain the laser beam and protect bystanders.

3. Device Inspection: Check the laser cleaner for any visible damage, loose connections, or issues with the cooling system.

2. Setting Laser Parameters

Configure the laser settings based on the material and type of contaminants. Key parameters include laser power, pulse frequency, and spot size. Refer to the manufacturer’s guidelines for recommended settings.

Laser Cleaning Before & After

Conduct a test on a small, inconspicuous area to verify that the settings are effective without damaging the surface.

3. Laser Alignment and Testing

Position the laser head so that the beam is precisely aimed at the target area. Use the aiming laser to ensure the beam is clear and stable. Perform a brief test scan to observe the cleaning effect. Adjust the settings if necessary to achieve optimal results.

4. Initiating the Cleaning Process

Begin cleaning by scanning the laser beam evenly across the surface at a consistent speed. Avoid dwelling on one spot to prevent overheating or damage. For thick or stubborn contaminants, multiple passes may be required. Monitor the process to ensure even cleaning.

5. Checking the Cleaning Effect

After cleaning, visually inspect the surface to ensure all contaminants have been removed and the surface is smooth and residue-free. If further cleaning is needed, adjust the parameters and repeat the process until the desired result is achieved.

6. Equipment Maintenance and Cleanup

Once done, turn off the device and disconnect it from power. Clean the laser head and optical components to remove any debris. Check the cooling system and replace filters if necessary. Store the equipment in a dry, secure location to maintain its longevity.

By following these steps, users can safely and effectively operate a handheld laser cleaner to achieve precise and efficient cleaning results on various surfaces.

The pulse laser cleaning machine has four power options for you to choose from 100W, 200W, 300W, and 500W.

The pulsed fiber laser featuring high precision and no heat affection area usually can reach an excellent cleaning effect even if under a low power supply. Due to the noncontinuous laser output and high peak laser power, the pulsed laser cleaner is more energy-saving and suitable for fine parts cleaning.

The fiber laser source has premium stability and reliability, with the adjustable pulsed laser, is flexible and serviceable in rust removal, paint removal, stripping coating, and eliminating oxide and other contaminants.

The CW laser cleaning machine has four power options for you to choose from: 1000W, 1500W, 2000W, and 3000W depending on cleaning speed and cleaning area size.

Different from pulse laser cleaner, the continuous wave laser cleaning machine can reach higher-power output which means higher speed and larger cleaning covering space.

That’s an ideal tool in shipbuilding, aerospace, automotive, mold, and pipeline fields due to the highly efficient and steady cleaning effect regardless of the indoor or outdoor environment.

Commonly Asked Question: Handheld Laser Cleaner

Q1: Can a Handheld Laser Cleaner be Used on Delicate Surfaces like Wood or Stone?

Yes, handheld laser cleaners are versatile and can be used on a variety of materials, including wood, stone, metal, and even delicate artifacts.

The key is to adjust the laser parameters (e.g., lower power and finer spot size) to avoid damaging the surface. Always perform a test on a small, inconspicuous area before starting the main cleaning process.

Q2: Is it Safe to Use a Handheld Laser Cleaner?

Handheld laser cleaners are safe when used correctly.

However, they emit high-energy laser beams that can be hazardous to the eyes and skin. Always wear appropriate PPE, such as laser safety goggles and gloves. Additionally, ensure the work area is well-ventilated and secure to prevent accidental exposure.

Q3: How Often Should I Maintain my Handheld Laser Cleaner?

Regular maintenance is essential to ensure the longevity and optimal performance of your laser cleaner.

After each use, clean the laser head and optical components to remove any debris. Check the cooling system and replace filters as needed. Perform a thorough inspection of the device every few uses to identify any potential issues early. Proper maintenance can significantly extend the life of your equipment.

Post time: Jan-24-2025