Armed with this knowledge, you'll be well-equipped to make an informed decision when purchasing a fiber laser that best aligns with your needs and goals.

We hope this buying guide will serve as an invaluable resource on your journey to acquiring a fiber laser that will take your business or projects to new heights of success.

1. What a Fiber Laser Marker is for?

When it comes to marking metals, the technology of fiber laser marking has become increasingly popular in various industries.

Its versatility and ability to create precise, permanent markings have made it a preferred choice for a wide range of applications.

Understanding Fiber Laser Marking is a Process.

Fiber laser marking is a technique that utilizes a high-powered laser beam generated from rare-earth-doped fiber optics.

This technology allows for the creation of high-contrast, indelible markings on different types of metals.

One of the common applications of fiber laser marking is the engraving of initials on knives or jewelry rings.

This technique offers an aesthetically pleasing way to personalize these items, adding a touch of uniqueness and value.

Whether it's a sentimental gift or a branding requirement, the markings are clear, permanent, and resistant to wear.

In industries where traceability is crucial, such as automotive, aerospace, or electronics.

Fiber laser marking is extensively used to engrave serial numbers on screws or nut bolts.

These unique identifiers help in tracking and quality control processes.

Ensuring easy identification, inventory management, and counterfeit prevention.

Fiber laser marking ensures that the serial numbers are permanently marked, even in harsh environments.

Making it an ideal choice for durable and reliable traceability solutions.

2. How to Choose: Based on Use Case

When it comes to selecting a fiber laser marker, it's important to consider your specific use case.

Fiber marking machines come in three main types: handheld, portable, and stationary.

Each type has its own advantages and suitability depending on the intended application.

A handheld fiber laser marker offers the unique ability to mark on immovable objects.

This characteristic makes it particularly useful in scenarios where bringing the object to the laser marking machine is impractical or impossible.

This portable option is often favored by professionals who need to mark objects on-site or in remote locations.

However, it's important to note that handheld fiber laser markers may have limitations in terms of production scale.

Portable Fiber Laser Marker:

For small-scale production or hobbyist applications, a portable fiber laser marker provides a suitable solution.

These compact machines offer flexibility and ease of use, making them ideal for periodic or occasional marking needs.

While they may lack the robustness and stability of stationary fiber marking stations.

Portable markers are more affordable and can be moved easily using wheels.

It's crucial to handle the fiber cable with care to avoid any costly replacements due to human error.

If you have a dedicated space in your factory or workshop, a stationary fiber marking station is highly recommended.

These machines offer enhanced stability and security compared to portable options.

While they may lack the portability of handheld or portable markers, stationary fiber marking stations excel in terms of durability and precision.

They are designed for larger production volumes and can handle continuous marking operations without compromising quality.

Additionally, stationary markers often provide upgrade options such as automation integration.

Allowing for seamless integration into existing production lines.

After deciding on the type of laser marker that suits your needs, there are a few additional factors to consider:

Production Scale: Evaluate the volume of marking required for your application. If you have high production demands, a stationary fiber marking station may be the most efficient choice.

Space Availability: Assess the available space in your facility. If you have a dedicated area for laser marking, a stationary marker is an excellent option. However, if space is limited or if you require on-site marking, a portable or handheld marker may be more suitable.

Automation Needs: If you require automation integration or plan to streamline your marking process, a stationary fiber marking station offers more upgrade options and compatibility with other equipment.

From Handheld to Stationary Fiber Laser Markers

It can be Hard to Decide

3. How to Choose: Based on Production

Selecting the appropriate fiber laser marker for your production requirements is crucial to achieving efficient and high-quality marking results.

One of the key considerations in this process is determining the power of the laser marker.

Additionally, it's essential to understand the variations in performance that can arise from different brands producing laser sources.

Understanding Laser Power for Fiber Laser Markers:

The power of a fiber laser marker plays a vital role in determining the marking speed, depth, and overall performance of the machine.

When it comes to small projects, a 30W or 50W fiber laser is generally considered an excellent starting point.

These power levels offer a good balance between affordability and versatility, making them suitable for many applications.

However, it's essential to assess your specific marking needs, material types, and desired marking depth to determine the optimal power requirement for your production.

To ensure you choose the right fiber laser marker for your production needs, it is highly recommended to engage in discussion with pre-sales professionals.

These experts possess in-depth knowledge and experience in the field and can provide valuable insights and guidance.

By discussing your production scale, marking requirements, and specific applications, they can help determine the appropriate laser power and other features necessary for optimal performance.

The Importance of Brand Variation in Laser Sources:

It's worth noting that, similar to graphics cards, the same model name produced by different brands can result in varying performances.

In the case of fiber laser markers, the laser source is a critical component that significantly impacts the overall marking capabilities.

Various reputable brands, such as JPT, Raycus, and Max, produce fiber laser sources.

However, it's important to understand that the performance and reliability of these sources may differ.

Evaluating the reputation, customer reviews and technical specifications of different brands can help you make an informed decision.

Choosing the right fiber laser marker based on your production requirements is a crucial step in achieving efficient and accurate marking results.

By carefully evaluating these factors, you can confidently choose a fiber laser marker that meets your production requirements and delivers exceptional marking performance.

4. How to Choose: Addons & Accessories

In addition to selecting the right fiber laser marker for your marking needs, incorporating suitable add-ons and accessories can enhance the functionality, efficiency, and versatility of your marking process.

Whether you have aspirations to sell marked products, prioritize environmental sustainability, or aim for full automation, there are various add-ons available to meet your specific requirements.

Rotary Device for Marking Cylindrical Objects:

If you plan to sell marked tumblers or other cylindrical objects, a rotary device is essential.

This add-on enables precise and consistent marking on curved surfaces by rotating the object while the laser marks it.

The rotary device ensures that the marking remains aligned and accurate, even on irregular or curved surfaces.

With this accessory, you can expand your product offerings and cater to a wider range of customer demands.

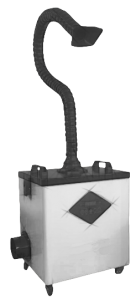

Fume Extractor for Environmental Friendliness:

To maintain a clean and healthy workspace while minimizing the environmental impact, a fume extractor is a valuable addition.

Fiber laser marking involves the emission of fumes and particles during the marking process.

A fume extractor effectively captures and filters these fumes, ensuring proper ventilation and reducing exposure to harmful substances.

By investing in a fume extractor, you create a safe and sustainable working environment for yourself and your employees.

CCD Camera and Conveyor Belt for Automation:

For those seeking full automation in their marking process, incorporating a CCD camera and a conveyor belt can significantly streamline operations.

With this setup, materials such as screws can be placed on the conveyor belt, which transports them to the fiber laser marker.

The CCD camera, equipped with advanced imaging technology, automatically identifies and targets the screws, ensuring precise and accurate marking without the need for human intervention.

Once marked, the screws can be seamlessly transferred to the packaging line for further processing.

This automation setup is ideal for mass marking needs, maximizing efficiency and productivity.

Choosing the right add-ons and accessories for your fiber laser marker can greatly enhance your marking capabilities and overall efficiency.

By carefully considering these add-ons and accessories, you can tailor your fiber laser marking system to meet your unique needs, unlocking new possibilities and driving success in your marking applications.

5. What is Mandatory for Safety?

When it comes to working with laser marking equipment, ensuring safety is of paramount importance.

Laser beams can pose potential risks to the eyes and skin if proper precautions are not taken.

Prioritizing Safety: The Core Requirement

In any laser marking environment, safety should always be the top priority.

Even though the laser marking process may appear visually harmless, it is crucial to understand that laser beams can cause serious damage to the eyes if exposed directly or reflected off a reflective surface.

Therefore, it is mandatory to adopt necessary safety measures to protect one's eyesight.

Essential Safety Equipment: Safety Glasses

The most critical safety accessory when working with laser marking systems is a pair of suitable safety glasses.

Safety glasses are specifically designed to shield the eyes from harmful laser radiation.

When choosing safety glasses, it is essential to consider their ability to block the specific wavelengths emitted by fiber lasers, which typically range between 1,000 and 1,100 nm.

Selecting Properly Fitting Safety Glasses

To ensure maximum protection, it is crucial that the safety glasses fit snugly around the eyes, leaving no gaps that could allow laser radiation to enter.

Ill-fitting or loose safety glasses may compromise their effectiveness and leave the eyes vulnerable to potential harm.

Therefore, it is recommended to choose safety glasses that provide a secure and comfortable fit.

Certifications and Standards

When selecting safety glasses, look for those that comply with relevant safety standards and certifications.

These certifications ensure that the glasses have undergone rigorous testing to meet specific safety requirements.

Examples of recognized safety standards include ANSI Z87.1 in the United States and EN 207/208 in Europe.

Checking for these certifications guarantees that the safety glasses offer the necessary protection against laser radiation.

Additional Safety Measures

While wearing appropriate safety glasses is a fundamental safety requirement, it is also essential to adhere to other safety practices.

These may include:

Restricted Access: Restricting access to the laser marking area to authorized personnel only helps minimize the risk of accidental exposure.

Training and Education: Ensuring that all individuals working with laser marking systems receive proper training and education on laser safety protocols and best practices.

Controlled Environment: Maintaining a well-organized and controlled working environment, including clear labeling of laser hazards and implementing safety interlocks when necessary.

6. How to Choose Software?

Selecting the right software for your laser marker is a crucial aspect of optimizing its performance and efficiency.

While the software is often bundled with the laser marker itself, it is essential to consider its capabilities, compatibility, and the training package provided.

The Importance of Laser Marker Software

Laser marker software serves as the control center for your laser marking machine, enabling you to design and execute precise marking patterns, adjust parameters, and manage the marking process.

The software plays a vital role in achieving accurate and high-quality markings, ensuring efficient workflow, and facilitating seamless integration with other systems.

Key Considerations when Choosing Software

Compatibility: Ensure that the software is compatible with your laser marker and any other relevant equipment or systems you plan to use. Compatibility issues can hinder functionality and limit your capabilities.

Features and Functionality: Assess the features and functionality offered by the software. Look for capabilities such as vector-based design tools, barcode generation, serialization, image conversion, and the ability to import various file formats. Consider your specific marking requirements and choose software that aligns with your needs.

User Interface and Ease of Use: Evaluate the user interface of the software and its ease of use. A user-friendly interface with intuitive navigation and clear instructions can significantly enhance your productivity and minimize the learning curve.

Customization and Flexibility: Consider whether the software allows customization and flexibility in terms of designing unique marking patterns, adjusting settings, and integrating with external systems. The ability to tailor the software to your specific needs can be invaluable in achieving optimal results.

Training Packages for Laser Marker Software

When purchasing a laser marker, it is crucial to inquire about the training package provided alongside the machine.

Comprehensive training ensures that you are equipped with the necessary knowledge and skills to utilize the software and the laser marking machine to their fullest potential while prioritizing safety.

Training should cover various aspects, including:

Software Operation: Thorough training on the software's functionalities, user interface, and navigation, empowering you to harness its capabilities effectively.

Marking Techniques: Training should encompass different marking techniques, such as engraving, etching, and surface annealing, enabling you to apply the most suitable technique for your specific applications.

Parameter Optimization: Understanding how to optimize marking parameters, such as laser power, speed, frequency, and focus, to achieve desired marking results.

Safety Guidelines: Comprehensive training should emphasize safety protocols, ensuring that you understand the potential risks associated with laser marking and how to mitigate them.

Congratulations!

By following this article, you just picked out a virtual machine in your mind.

If you enjoyed the content, please consider subscribing to our YouTube channel.

Post time: May-21-2024