With the rapid development of laser welding technology, the market is flooded with a wide variety of laser welding devices, ranging from high-quality laser welder machines to those with inconsistent performance.

Many buyers are unsure how to begin selecting the ideal laser welder for their specific needs.

To help you make an informed decision, here are some key factors to consider when choosing the best laser welding device.

1. Is Your Product Suitable For Laser Welding?

Before purchasing a laser welder, it is essential to evaluate whether your product is compatible with laser welding technology.

Most manufacturers of laser welding devices offer free sample testing services. It’s advisable to take advantage of these services to see the welding results firsthand.

This will help you confirm if a laser welder machine meets your product's specific requirements, ensuring you achieve the desired welding quality.

In addition,if you are not sure if your product is suitable for laser welding, you can go to the following page to confirm:>>APPLICATION OVERVIEW<<

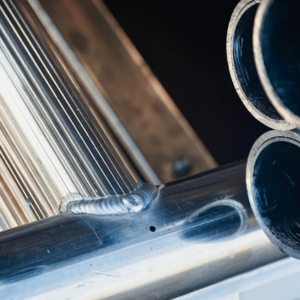

Metal Laser Welding Machine Aluminum

2. Choosing Suitable Laser Welder Power

The laser generator is the core component of any laser welding machine, and its power level is a critical factor to consider.

Generally, the higher the power, the higher the price due to the increased demands on laser rods and cooling systems.

The depth and thickness of the weld directly determine the required power of the laser welder.

For example, thicker or deeper welds will necessitate a higher-powered laser welding device.

Our website offers laser welding machines with different power, if you are interested you can click here to learn more:>>LASER WELDER MACHINE<<

Want to Buy a Laser Welder?

3. Choosing Laser Welder Based On Application

Laser welders come with various hardware configurations depending on their intended applications.

For instance, welding sheet metal enclosures, stainless steel and carbon steel corner joints, or overlapping welds will require different setups.

Additionally, there are specialized laser welder machines for applications like fiber optic cable welding.

Be sure to choose the hardware configuration that matches your primary usage scenario, as this will significantly affect both performance and price.

4. Selecting Laser Welding Device: Budget and Usage Tips

While some buyers may lean toward international brands, these laser welding devices often come with a higher price tag.

However, laser welder machines manufactured in China have become highly competitive due to advancements in technology.

Many Chinese laser welding devices now meet international standards, offering reliable performance at more affordable prices.

Additionally, purchasing locally-made machines can provide better after-sales service and support, making them a more convenient option in the event of technical issues.

When choosing a laser welding device, balance your budget with your specific usage needs to make a practical and cost-effective decision.

5. Conclusion

Selecting the right laser welder machine involves careful consideration of your product's suitability for laser welding, the required power, appropriate hardware configurations, and your budget.

By focusing on these aspects, you can identify a laser welding device that aligns with your production needs while delivering superior performance and cost efficiency.

Whether you are exploring laser welders for sale or seeking to enhance your manufacturing capabilities, these guidelines will help you make an informed and confident decision.

Handheld Laser Welder

Want To Know More About Laser Welder?

Related Machine: Laser Welders

With a compact and small machine appearance, the portable laser welder machine is equipped with a moveable handheld laser welder gun which is lightweight and convenient for multi laser welding applications at any angles and surfaces.

Optional various types of laser welder nozzles and automatic wire feeding system make laser welding operation easier and that is friendly for beginner.

High-speed laser welding greatly increases your production efficiency and output while enabling a excellent laser welding effect.

Even though small laser machine size, the fiber laser welder structures are stable and sturdy.

The handheld fiber laser welder is designed with five parts: the cabinet, the fiber laser source, the circular water-cooling system, the laser control system, and the hand held welding gun.

The simple but stable machine structure makes it easier for the user to move the laser welding machine around and weld the metal freely.

The portable laser welder is commonly used in metal billboard welding, stainless steel welding, sheet metal cabinet welding, and large sheet metal structure welding.

Post time: Jan-07-2025