This Article is For:

If you’re using a CO2 laser machine or considering purchasing one, understanding how to maintain and extend the life of your laser tube is crucial. This article is for you!

What are the CO2 laser tubes, and how do you use the laser tube to extend the service life of the laser machine, etc are explained here.

You will get the most out of your investment by focusing on the care and maintenance of CO2 laser tubes, particularly glass laser tubes, which are more common and require more attention compared to metal laser tubes.

Two Types of CO2 Laser Tube:

Glass Laser Tubes are popular and widely used in CO2 laser machine, due to their affordability and versatility. However, they are more fragile, have a shorter lifespan, and require regular maintenance to ensure optimal performance.

Metal Laser Tubes are more durable and have a longer lifespan, requiring little to no maintenance, but they come with a higher price tag.

Given the popularity and maintenance needs of glass tubes, this article will focus on how to care for them effectively.

1. Cooling System Maintenance

The cooling system is the lifeblood of your laser tube, preventing it from overheating and ensuring it operates efficiently.

• Check Coolant Levels Regularly: Ensure the coolant levels are adequate at all times. A low coolant level can cause the tube to overheat, leading to damage.

• Use Distilled Water: To avoid mineral buildup, use distilled water mixed with an appropriate antifreeze. This mixture prevents corrosion and keeps the cooling system clean.

• Avoid Contamination: Regularly clean the cooling system to prevent dust, algae, and other contaminants from clogging the system, which can reduce cooling efficiency and damage the tube.

Winter Tips:

In the cold weather, room temperature water inside the water chiller and glass laser tube might freeze because of the low temperature. It will damage your glass laser tube and may lead to the explosion of it. So please remember to add antifreeze when it’s necessary. How to add antifreeze into water chiller, check this guide out:

2. Optics Cleaning

The mirrors and lenses in your laser machine play a critical role in directing and focusing the laser beam. If they become dirty, the quality and power of the beam can degrade.

• Clean Regularly: Dust and debris can accumulate on optics, especially in dusty environments. Use a clean, soft cloth and an appropriate cleaning solution to gently wipe the mirrors and lenses.

• Handle with Care: Avoid touching the optics with your bare hands, as oils and dirt can easily transfer and damage them.

Video Demo: How to Clean & Install Laser Lens?

3. Appropriate Working Environment

Not only for the laser tube, but the whole laser system will also show the best performance in a suitable working environment. Extreme weather conditions or leave the CO2 Laser Machine outside in public for a long time will shorten the service life of the equipment and degrade its performance.

• Temperature Range:

20℃ to 32℃ (68 to 90 ℉) air-conditional will be suggested if not within this temperature range

• Humidity Range:

35%~80% (non-condensing) relative humidity with 50% recommended for optimal performance

4. Power Settings and Usage Patterns

Operating your laser tube at full power continuously can significantly reduce its lifespan.

• Moderate Power Levels:

Running your CO2 laser tube consistently at 100% power can reduce its lifespan. It’s typically recommended to operate at no more than 80-90% of the maximum power to avoid wear on the tube.

• Allow for Cooling Periods:

Avoid long periods of continuous operation. Allow the tube to cool down between sessions to prevent overheating and wear.

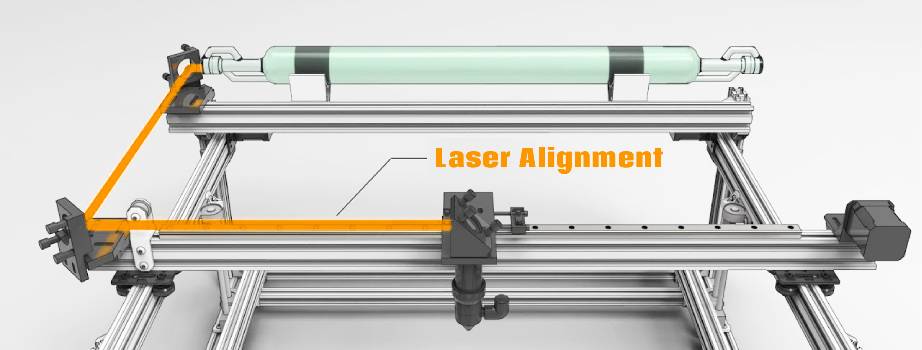

5. Regular Alignment Checks

Proper alignment of the laser beam is essential for accurate cutting and engraving. Misalignment can cause uneven wear on the tube and affect the quality of your work.

• Check Alignment Regularly:

Especially after moving the machine or if you notice a decline in cutting or engraving quality, check the alignment using alignment tools.

Whenever possible, operate at lower power settings that are sufficient for your task. This reduces the stress on the tube and prolongs its life.

• Correct Any Misalignments Promptly:

If you detect any misalignment, correct it immediately to avoid further damage to the tube.

6. Do Not Turn ON and OFF the Laser Machine throughout the Day

By decreasing the number of times of experiencing high and low-temperature conversion, the sealing sleeve at one end of the laser tube will show better gas tightness.

Turn off your laser cutting machine during lunch or diner break can be acceptable.

The glass laser tube is the core component of the laser cutting machine, it’s also a consumable good. The average service life of a CO2 glass laser is about 3,000 hrs., approximately you need to replace it every two years.

We Suggest:

Buying from a professional and reliable laser machine supplier is important for your consistent and high-quality production.

There are some top brands of CO2 laser tubes we cooperate with:

✦ RECI

✦ Yongli

✦ SPT Laser

✦ SP Laser

✦ Coherent

✦ Rofin

...

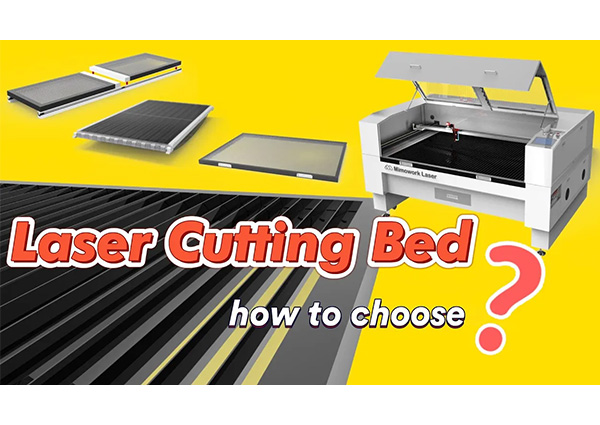

Popular CO2 Laser Machine Series

• Laser Cutter and Engraver for Acrylic & Wood & Patch:

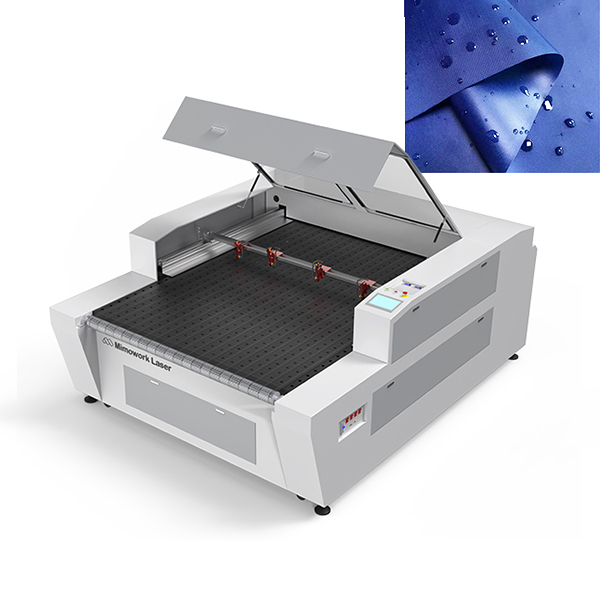

• Laser Cutting Machine for Fabric & Leather:

• Galvo Laser Marking Machine for Paper, Denim, Leather:

Get More Advice about Selecting Laser Tube & Laser Machine

FAQ

1. How to Remove the Scale in the Glass Laser Tube?

If you have used the laser machine for a while and find out there are scales inside the glass laser tube, please clean it up immediately. There are two methods you can try:

✦ Add citric acid into warm purified water, mix and inject from the water inlet of the laser tube. Wait for 30 minutes and pour out the liquid from the laser tube.

✦ Add 1% hydrofluoric acid into the purified water and mix and inject from the water inlet of the laser tube. This method only applies to extremely serious scales and please wear protective gloves while you are adding hydrofluoric acid.

2. What is the CO2 Laser Tube?

As one of the earliest gas lasers developed, the carbon dioxide laser (CO2 laser) is one of the most useful types of lasers for processing non-metal materials. The CO2 gas as the laser-active medium plays an important role in the process of generating the laser beam. During the usage, the laser tube will undergo thermal expansion and cold contraction from time to time. The sealing at the light outlet is therefore subject to higher forces during laser generating and may show a gas leak during cooling. This is something that can’t be avoided, whether you are using a glass laser tube (as known as DC LASER – direct current) or RF Laser (radio frequency).

3. How to Replace CO2 Laser Tube?

How to replace CO2 laser glass tube? In this video, you can check out the CO2 laser machine tutorial and specific steps from CO2 laser tube installation to changing the glass laser tube.

We take the laser co2 1390 installation for example to show you.

Usually, the co2 laser glass tube is located on the back and side of the co2 laser machine. Put the CO2 laser tube on the bracket, connect the CO2 laser tube with the wire and water tube, and adjust the height to level the laser tube. That’s done well.

Then how to maintain a CO2 laser glass tube? Check out the 6 tips for CO2 laser tube maintenance we mentioned above.

CO2 Laser Tutorial & Guide Videos

How to Find Focus of Laser Lens?

Perfect laser cutting and engraving result means appropriate CO2 laser machine focal length. How to find the focus of the laser lens? How to find the focal length for a laser lens? This video answers you with specific operation steps for adjusting the co2 laser lens to find the right focal length with a CO2 laser engraver machine. The focus lens co2 laser concentrates the laser beam on the focus point which is the thinnest spot and has a powerful energy. Adjusting the focal length to the appropriate height significantly impacts the quality and precision of laser cutting or engraving.

How does a CO2 Laser Cutter Work?

Laser cutters use focused light instead of blades to shape materials. A "lasing medium" is energized to produce an intense beam, which mirrors and lenses guide into a tiny spot. This heat vaporizes or melts bits away as the laser moves, allowing intricate designs to be etched slice by slice. Factories use them to mass produce accurate parts quickly from things like metal and wood. Their precision, versatility and minimal waste has revolutionized manufacturing. Laser light proves a powerful tool for precise cutting!

How Long will a CO2 Laser Cutter Last?

Every manufacturer investment has longevity considerations. CO2 laser cutters gainfully serve production needs for years when properly maintained. While individual unit lifespan varies, awareness of common lifespan factors helps optimize upkeep budgets. Average service periods are surveyed from laser users, though many units exceed estimates with routine component validation. Longevity ultimately depends on application demands, operating environments, and preventative care regimens. With attentive custodianship, laser cutters reliably enable efficient fabrication for as long as required.

What can a 40W CO2 Laser Cut?

Laser wattage speaks to capability, yet material properties matter too. A 40W CO2 tool processes with care. Its gentle touch handles fabrics, leathers, wood stocks up to 1/4”. For acrylic, anodized aluminum, it limits scorching with fine settings. Though weaker materials limit feasible dimensions, crafts still flourish. One mindful hand guides tool potential; another sees opportunity everywhere. A laser gently shapes as directed, empowering vision shared between man and machine. Together may we seek such understanding, and through it nourish expression for all people.

Any Questions about Laser Machine or Laser Maintenance?

You Might be Interested in:

Post time: Sep-01-2024