Laser engraved leather is the new fashion in leather projects! Intricate engraved details, flexible and customized pattern engraving, and super fast engraving speed definitely surprise you! Only need one laser engraver machine, no need for any dies, no need for knife bits, the leather engraving process can be realized at a fast speed. Therefore, laser engraving leather not only greatly increases productivity for leather products manufacturing, but also is a flexible DIY tool to meet all kinds of creative ideas for hobbyists.

from

Laser Engraved Leather Lab

So How to laser engrave leather? How to choose the best laser engraving machine for leather? Is laser leather engraving really superior to other traditional engraving methods like stamping, carving, or embossing? What projects can the leather laser engraver finish?

▶ Operation Guide: How to Laser Engrave Leather?

Depending on the CNC system and precise machine components, the acrylic laser cutting machine is automatic and easy to operate. You just need to upload the design file to the computer, and set the parameters according to material features and cutting requirements. The rest will be left to the laser. It's time to free your hands and activate creativity and imagination in mind.

Step 1. prepare machine and leather

Leather Preparation: You can use the magnet to fix the leather to keep it flat, and better to wet the leather before laser engraving, but not too wet.

Laser Machine: choose the laser machine depending on your leather thickness, pattern size, and production efficiency.

▶

Step 2. set software

Design File: import the design file into the laser software.

Laser Setting: Set the speed and power for the engraving, perforating, and cutting. Test the setting using the scrap before real engraving.

▶

Step 3. laser engrave leather

Start Laser Engraving: ensure the leather is in the right position for accurate laser engraving, you can use a projector, template, or laser machine camera to position.

▶ What You Can Make with Leather Laser Engraver?

① Laser Engraving Leather

laser engraved leather keychain, laser engraved leather wallet, laser engraved leather patches, laser engraved leather journal, laser engraved leather belt, laser engraved leather bracelet, laser engraved baseball glove, etc.

② Laser Cutting Leather

laser cut leather bracelet, laser cut leather jewelry, laser cut leather earrings, laser cut leather jacket, laser cut leather shoes, laser cut leather dress, laser cut leather necklaces, etc.

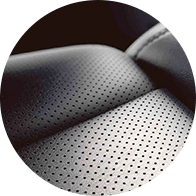

③ Laser Perforating Leather

perforated leather car seats, perforated leather watch band, perforated leather pants, perforated leather motorcycle vest, perforated leather shoes upper, etc.

What's your leather application?

Let's know and offer you advice

The great engraving effect benefits from the right leather laser engraver, suitable leather type, and correct operation. Laser engraving leather is easy to operate and master, but if you plan to start a leather business or improve your leather productivity, having a little knowledge of basic laser principles and machine types is better.

▶ What is laser engraving?

▶ What is the best laser for engraving leather?

CO2 Laser VS Fiber Laser VS Diode Laser

Recommend: CO2 Laser

▶ Recommended CO2 Laser Engraver for Leather

From MimoWork Laser Series

Working Table Size: 1300mm * 900mm (51.2” * 35.4 ”)

Laser Power Options: 100W/150W/300W

Overview of Flatbed Laser Cutter 130

A small laser cutting and engraving machine that can be fully customized to your needs and budget. The two-way penetration design allows you to place materials that extend beyond the cut width. If you want to achieve high-speed leather engraving, we can upgrade the step motor to a DC brushless servo motor and reach the engraving speed of 2000mm/s.

Working Table Size: 1600mm * 1000mm (62.9” * 39.3 ”)

Laser Power Options: 100W/150W/300W

Overview of Flatbed Laser Cutter 160

Customized leather products in different shapes and sizes can be laser engraved to meet continuous laser cutting, perforating, and engraving. The enclosed and solid mechanical structure provides a safe and clean working environment during laser cutting on leather. Besides, the conveyor system is convenient for rolling leather feeding and cutting.

Working Table Size: 400mm * 400mm (15.7” * 15.7”)

Laser Power Options: 180W/250W/500W

Overview of Galvo Laser Engraver 40

MimoWork Galvo Laser Marker and Engraver is a multi-purpose machine used for leather engraving, perforating, and marking (etching). Flying laser beam from a dynamic lens angle of inclination can realize fast processing within the defined scale. You can adjust the height of the laser head to fit the processed material’s size. Fast engraving speed and fine engraved details make the Galvo Laser Engraver your good partner.

▶ How to Choose Laser Engraving Machine for Leather?

You Need To Consider

> What information you need to provide?

> Our contact information

How to Choose Leather for Laser Engraving?

▶ What leather types are suitable for laser engraving?

Laser engraving is generally suitable for a variety of leather types, but the effectiveness can vary based on factors such as the leather's composition, thickness, and finish. Here are some common types of leather that are suitable for laser engraving:

Vegetable-Tanned Leather ▶

Full-Grain Leather ▶

Top-Grain Leather ▶

Suede Leather ▶

Split Leather ▶

Aniline Leather ▶

Nubuck Leather ▶

Pigmented Leather ▶

Chrome-Tanned Leather ▶

Natural leather, genuine leather, raw or treated leather like napped leather, and similar textiles such as leatherette, and Alcantara can be laser cut and engraved. Before engraving on a large piece, it's advisable to perform test engravings on a small, inconspicuous scrap to optimize settings and ensure the desired results.

▶ How to select and prepare the leather to be engraved?

▶ Some Tips & Attentions of laser engraving leather

Proper Ventilation: Ensure proper ventilation in your workspace to eliminate smoke and fumes generated during engraving. Consider using a fume extraction system to maintain a clear and safe environment.

Focus the Laser: Properly focus the laser beam on the leather surface. Adjust the focal length to achieve sharp and precise engraving, especially when working on intricate designs.

Masking: Apply masking tape to the leather surface before engraving. This protects the leather from smoke and residue, providing a cleaner finished look. Remove the masking after engraving.

Adjust Laser Settings: Experiment with different power and speed settings based on the type and thickness of the leather. Fine-tune these settings to achieve the desired engraving depth and contrast.

Monitor the Process: Keep a close eye on the engraving process, especially during the initial tests. Adjust settings as needed to ensure consistent and high-quality results.

▶ Machine Upgrade to simplify your work

Video: Projector Laser Cutter & Engraver for Leather

You may be interested

▶ Advantages of Laser Cutting & Engraving Leather

▶ Tools Comparison: Carving VS. Stamping VS. Laser

▶ Laser Leather Trend

Laser engraving on leather is a growing trend driven by its precision, versatility, and ability to create intricate designs. The process allows for efficient customization and personalization of leather products, making it popular for items like accessories, personalized gifts, and even large-scale production. The technology's speed, minimal material contact, and consistent results contribute to its appeal, while the clean edges and minimal waste enhance the overall aesthetics. With the ease of automation and suitability for various leather types, CO2 laser engraving is at the forefront of the trend, offering a perfect blend of creativity and efficiency in the leatherworking industry.

Any confusion or questions for the leather laser engraver, just inquire us at any time

Post time: Jan-08-2024